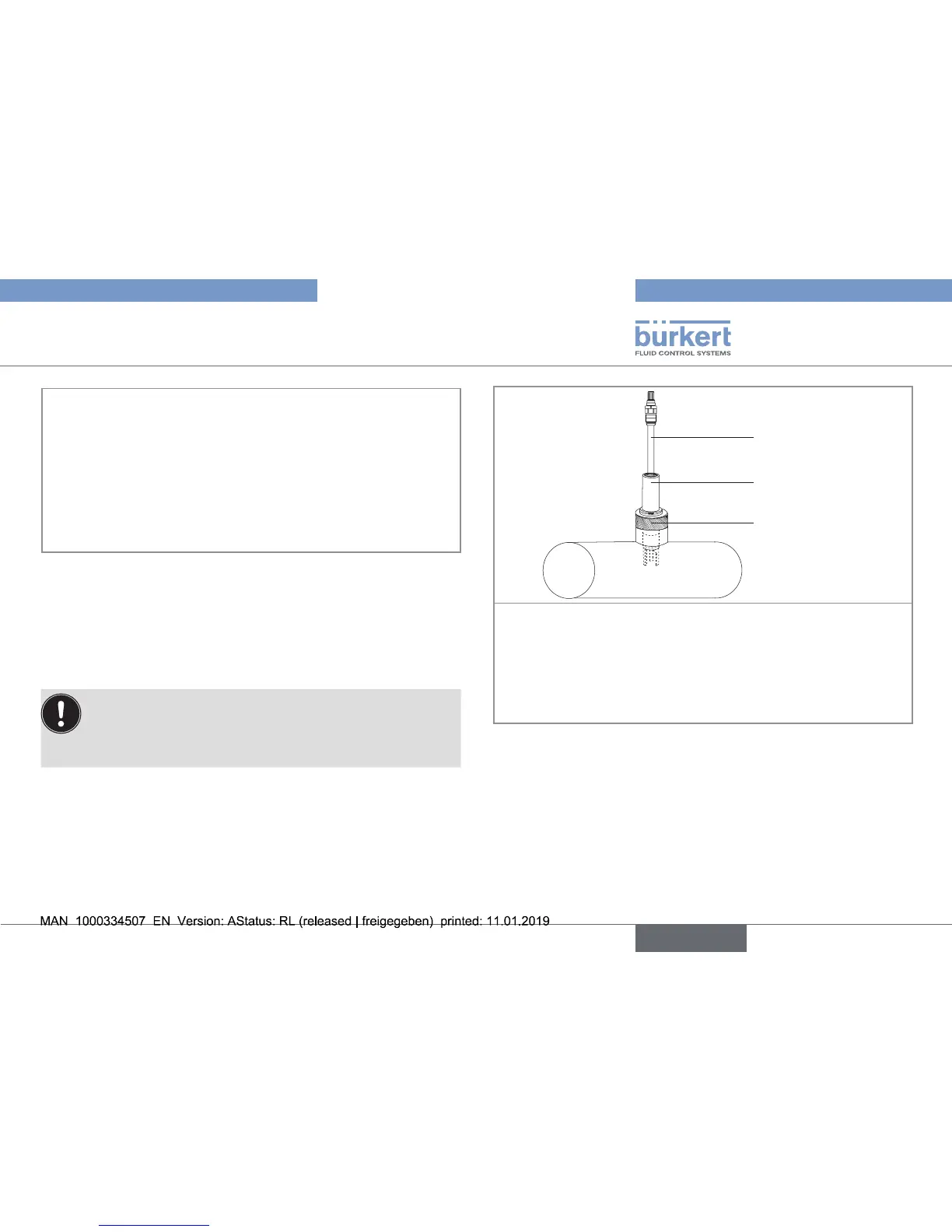

→ Make sure the direct welding holder is mounted onto the pipe

or on the vessel.

→ Make sure the product and the holder are not damaged.

→ Make sure all O-rings are in place in their appropriate grooves,

and are not damaged.

→ Insert the seal pusher 2 into the holder 3.

→ Screw the product 1 into the seal pusher 2 using a tightening

torque of 2...3 N·m (1.48...2.21 lbf·ft).

Fig. 13: Installation of a 8221 with a PG13.5 connection onto a

direct welding holder onto a pipe or on a vessel

7.9. Product with a PG13.5 connection

onto a G1¼'' threaded hygienic

holder

• To avoid any mechanical damage to O-rings during

assembly, lightly grease them.

• After assembly, clean the product of any remaining drops

of grease.

2

1

3

(not delivered)

→ Make sure the product and the holder are not damaged.

→ Make sure all O-rings are in place in their appropriate grooves,

and are not damaged.

→ Make sure the holder 2 is mounted onto an adaptor 3 welded

onto the pipe or on the vessel.

→ Screw the product 1 in the holder 2.

Fig. 14: Installation of a 8221 with a PG13.5 connection onto a

holder with G1¼'' connection onto a pipe or on a vessel

25

Installation

Type 8221

Loading...

Loading...