19

107774-01- 9/17

NOTICE

Do not exceed maximum vent/combustion air system length. Refer to Tables 7.1B, 7.5, 7.13, and 7.21

in this section for maximum vent/combustion air system length.

Use only vent and combustion air terminals and terminal locations shown in Tables 7.5, 7.13 and

7.21.

5. Minimum Vent and Air Intake Lengths - Observe the minimum vent lengths shown in Tables 7.5, 7.13 and 7.21.

6. Clearances to Combustibles - Maintain the following clearances from the vent system to combustible construction:

• Vent - 1/4” (also observe clearances through both combustible and non-combustible walls - see 9)

• Air Intake - 0”

• Concentric Portion of Concentric Terminals - 0”

7. Pitch of Horizontal Vent Piping - Pitch all horizontal vent piping so that any condensate which forms in the piping will run

towards the boiler.

• Pitch CPVC/PVC vent piping 1/4” per foot.

• Pitch Polypropylene vent piping 5/8” per foot.

VII. Venting A. Vent System Design (continued)

Table 7.1B: Vent/ Air Intake Fitting Equivalent Length

CPVC/PVC Fitting

Equivalent

Length (ft)

PolyPro, Polyue

or InnoFlue

Vent Fitting

Equivalent

Length (ft)

FasNSeal Vent Fitting

Equivalent

Length (ft)

3” 90° Elbow (“Sanitary Bend”) 4.0 3” 90° Elbow 8.7

3” 90° Elbow 4.0

3” 45° Elbow 2.0 3” 45° Elbow 4.6

3” 45° Elbow 2.0

3” 90° Elbow (“Short Bend”) 10.0

3” Straight Tee 18.0

3” Coupling 0.0

3” Boot Tee 8.0

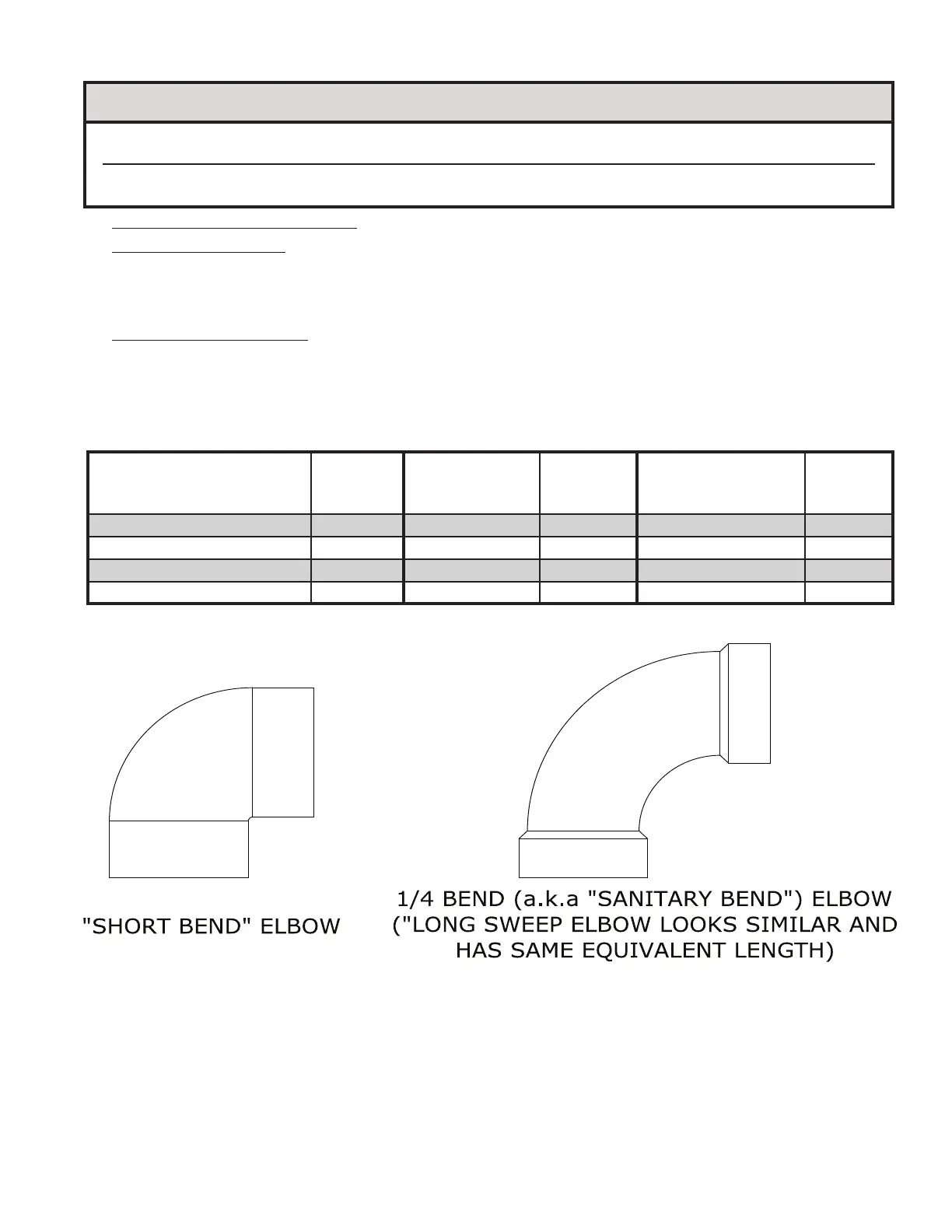

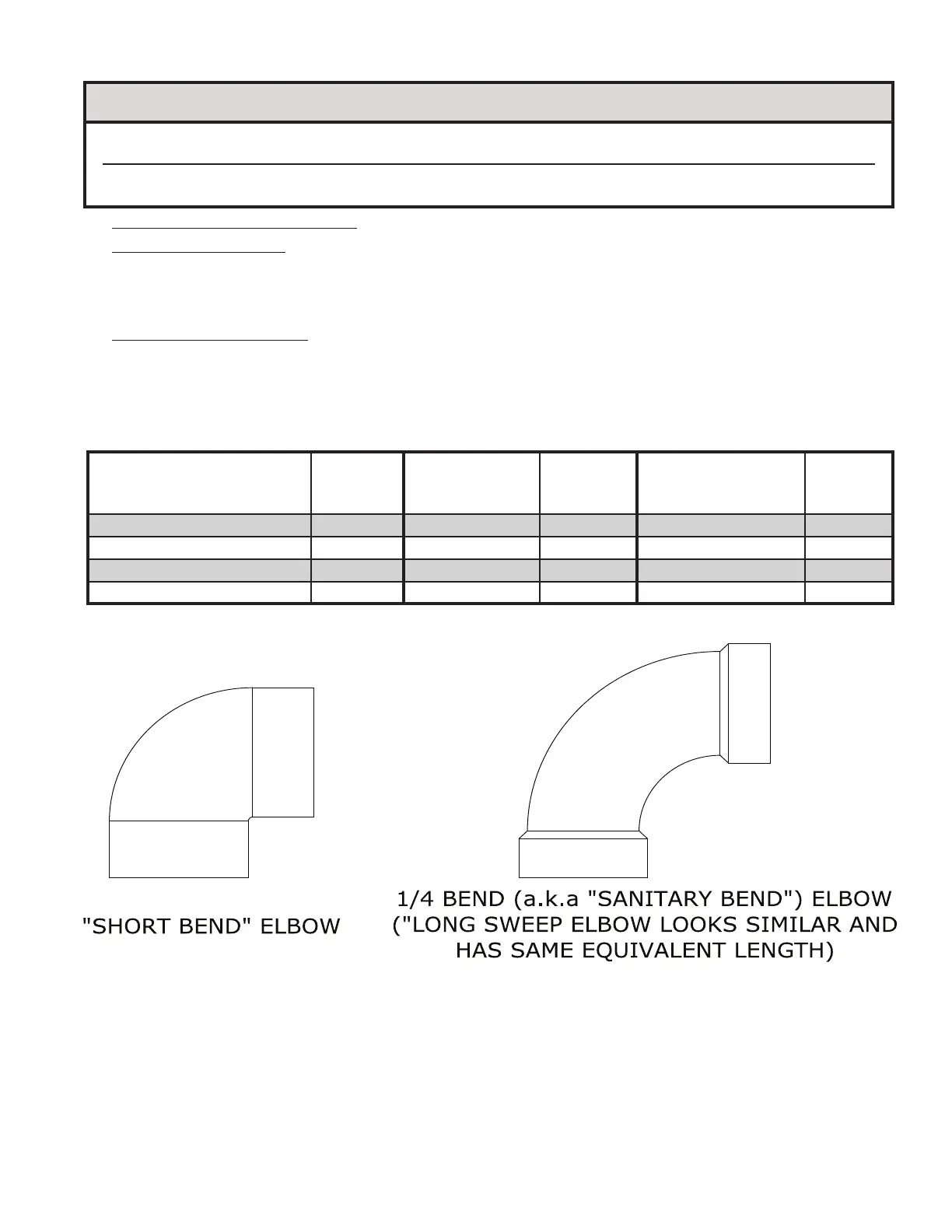

Figure 7.2: CPVC and PVC Elbows

Loading...

Loading...