23

107774-01- 9/17

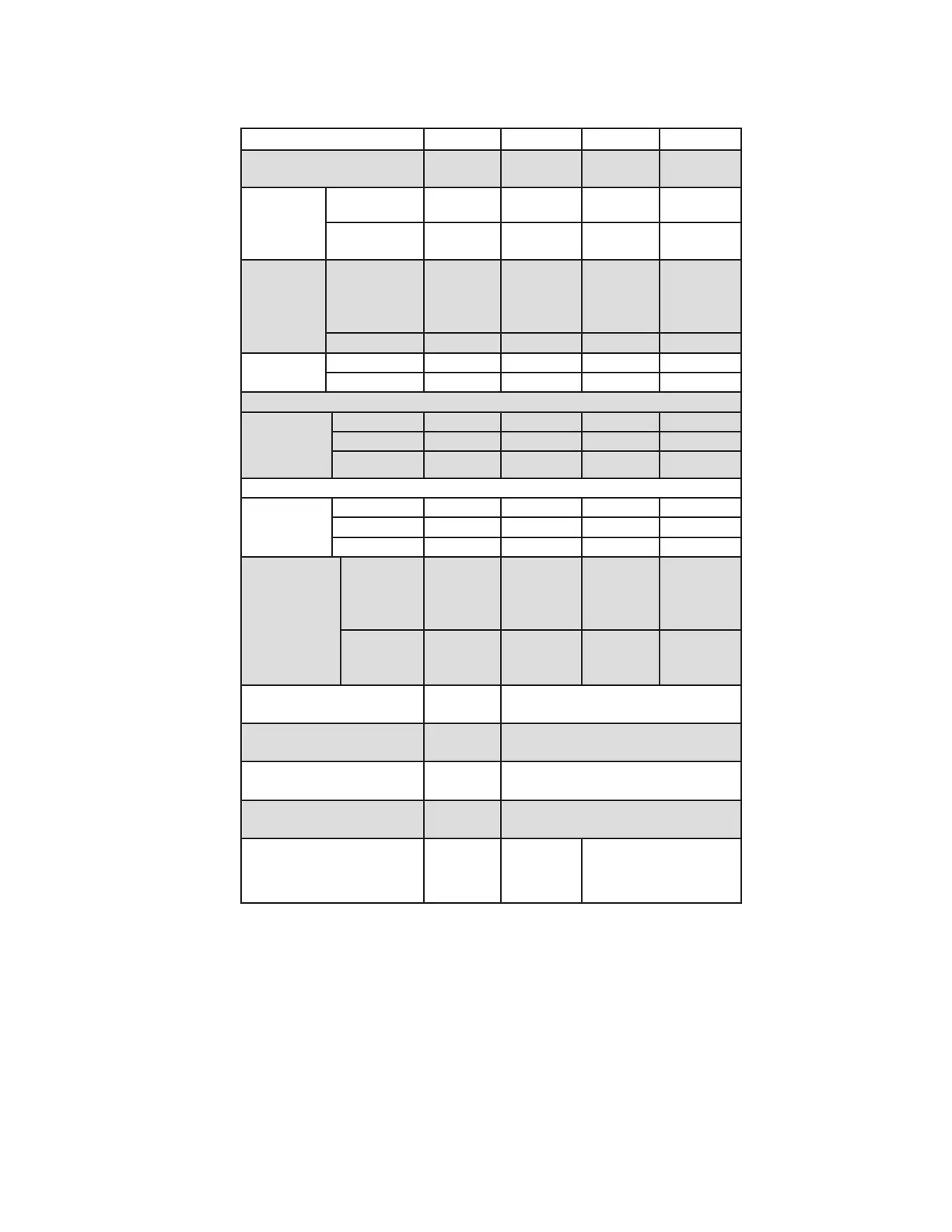

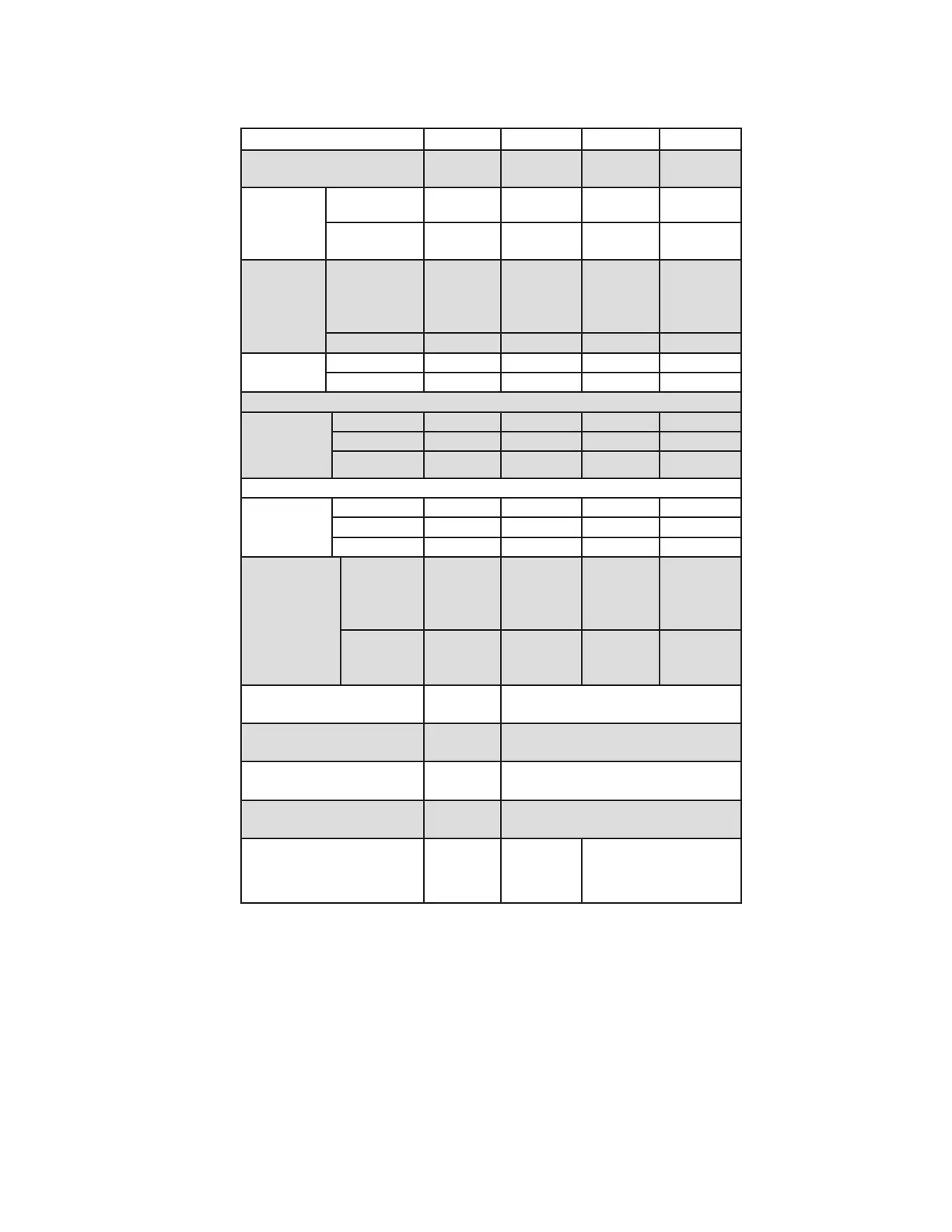

VII. Venting B. Design Requirements Unique to Horizontal Twin Pipe Venting Systems (continued)

Table 7.5: Summary of Horizontal Twin Pipe Venting Options

Vent Option 1 2 3 4

Illustrated in Figure

7.6, 7.7,

7.8

7.9, 7.10 7.9 7.9

Pipe

Penetration

through

Structure

Vent Wall Wall Wall Wall

Intake Wall Wall Wall Wall

Material

Vent

CPVC/

PVC

(Note 2)

DuraVent

PolyPro

(Rigid)

Selkirk

Polyue

Centro-

therm

InnoFlue

SW

Intake PVC PVC PVC PVC

Nominal

Diameter

Vent 3” 3” 3” 3”

Intake 3” 3” 3” 3”

Min Equivalent Vent Length:

Models

135 12” 12” 12” 12”

150 52” 52” 52” 52”

180 52” 52” 52” 52”

Max Equivalent Vent Length (Note 1):

Models

135 135ft 135ft 135ft 135ft

150 135ft 135ft 135ft 135ft

180 135ft 135ft 135ft 135ft

Terminal

Option A

(Fittings)

Vent

Coupling

w/screen

(Note 3)

3PPS-12B

or

3PPS-36B

w/screen

3PF-10UV

or

3PF-39UV

w/screen

ISEP03 or

ISEP0339

w/screen

Intake

Elbow

w/screen

(Note 3)

Elbow

w/screen

Elbow

w/screen

Elbow

w/screen

Terminal Option B

(Ipex Low Prole)

Ipex

#196985

Not Permitted

Terminal Option C

(DiversiTech HVENT)

HVENT-3 Not Permitted

Terminal Option D

(Ipex FGV Concentric)

Ipex

196006

Not Permitted

Terminal Option E

(DiversiTech CVENT)

CVENT-3 Not Permitted

Terminal Option F

(DuraVent Horizontal

Concentric)

Not

Permitted

3PPS-HK Not Permitted

Notes:

1. Max vent lengths shown also apply to the intake. For example, Vent Option #1 may have up to 135ft of vent pipe and also up to

135 ft of intake pipe.

2. First 30” of vent and vent Elbow connected to boiler must be CPVC. Downstream vent pipe can be PVC except as noted in text.

3. PVC Terminal coupling and inlet elbow may be offset on snorkels as shown in Figure 7.12.

Loading...

Loading...