72

107774-01 - 9/17

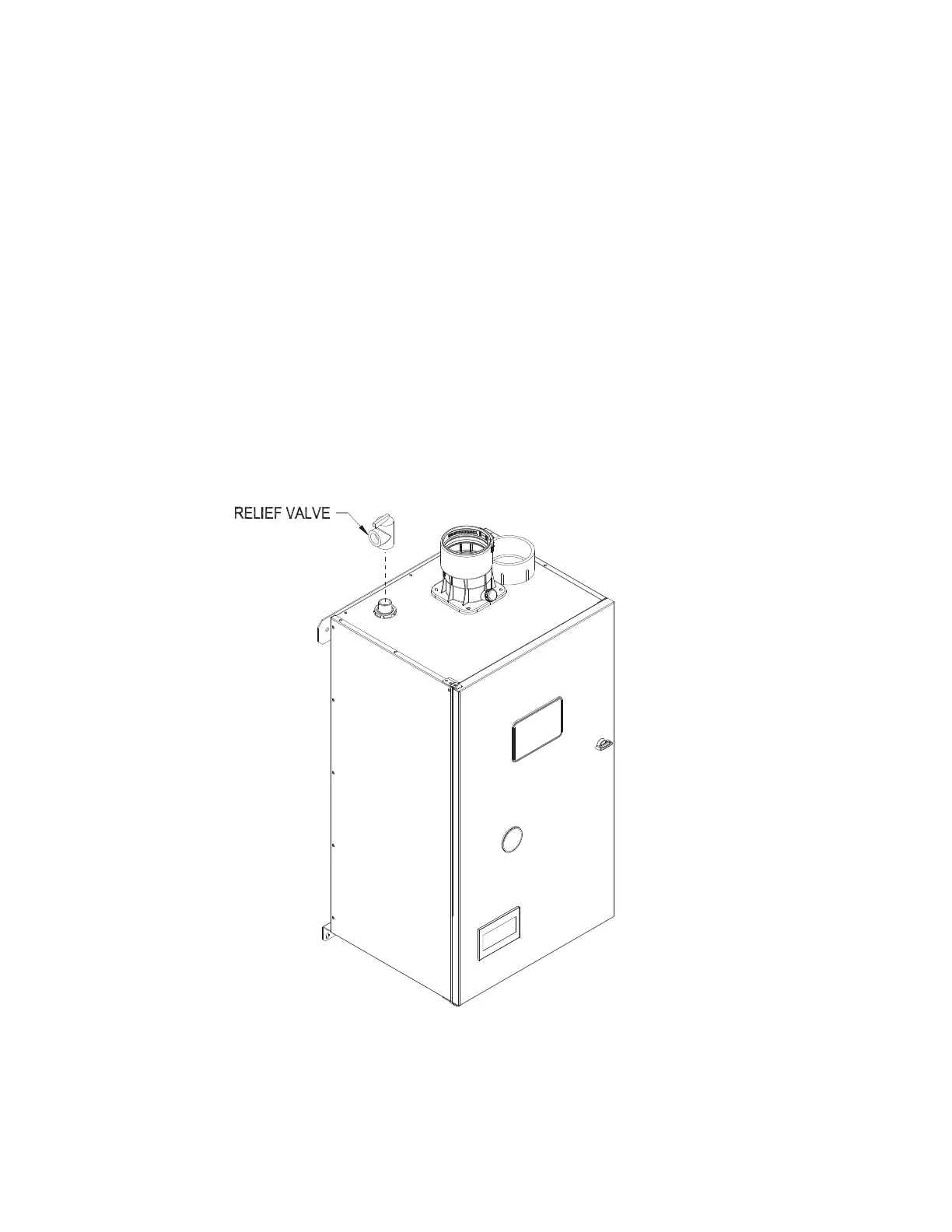

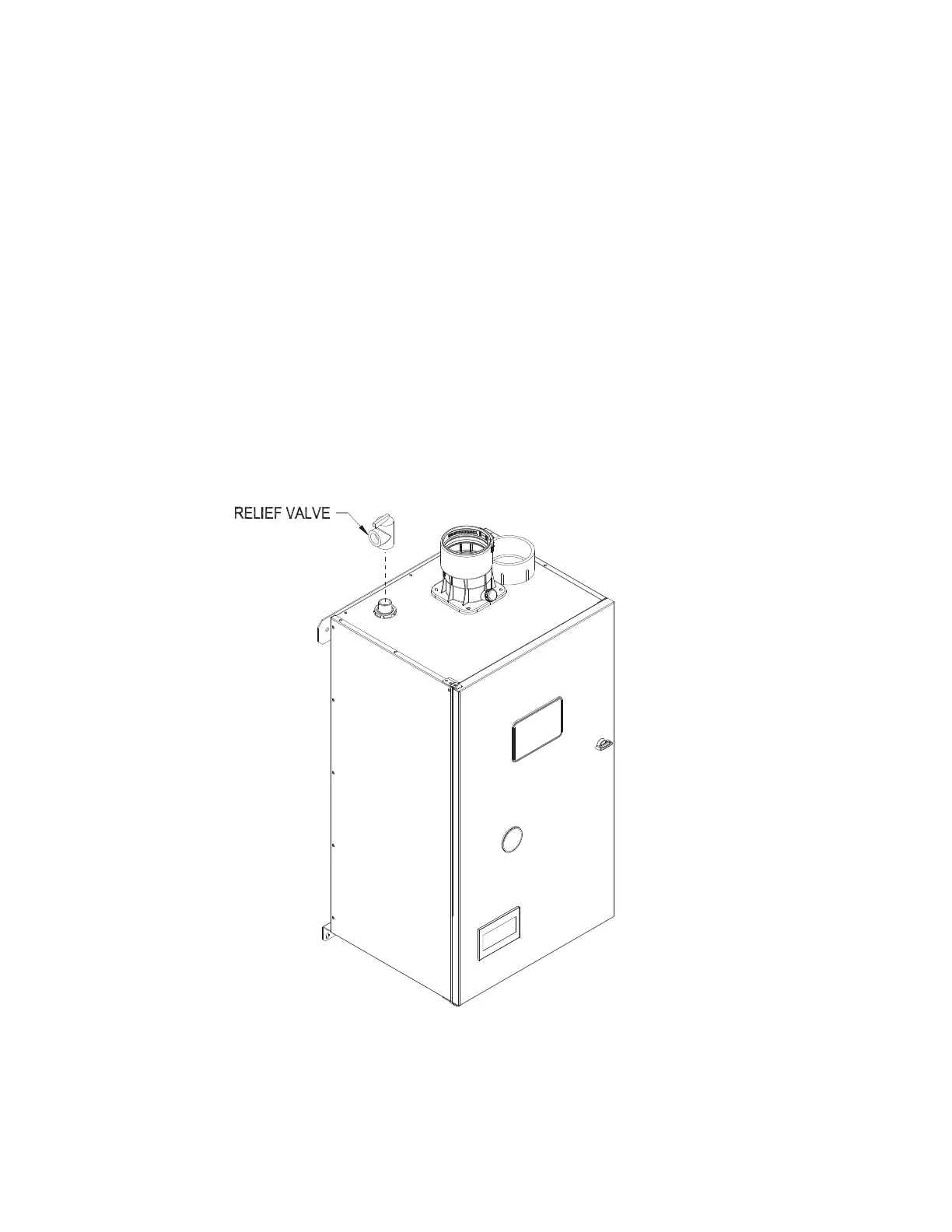

Figure 9.0: Factory Supplied Piping and Trim Installation

IX. System Piping (continued)

9. Drain Valve (required) – Install the drain valve (provided by the installer) as shown in Figure 9.2.

10. Low Water Cut-off (may be required by local jurisdiction) – Protection of this boiler against low water and/or

inadequateowisprovidedbytheUL353certiedowswitchbuiltintotheboiler.Thisisawatertubeboilerand

thisowswitchisthereforetheonlyeffectivewaytoprovidesuchprotection.SectionHG614(c)ofthe2015

ASMEboilerandPressureVesselCoderecognizestheuseofalistedowswitchinlieuofalowwatercut-offon

water tube boilers.

In the event that a local jurisdiction insists upon the installation of a low water cut-off with this boiler, refer to Part

XI and the low-water cut-off manufacturer’s instructions for proper wiring. Install the low water cut-off in the supply

piping at the point prescribed the local jurisdiction (generally at a point above the boiler).

If a probe type low water cut-off is used, be certain that it is located at a point in the piping from which air can

escape to an automatic air vent. Generally, this means that there should be no down-turns in the piping between

the low water cut-off and the point where the automatic air vent is installed. Failure to do this may result in nuisance

boiler shut-downs due to small amounts of air trapped around the probe.

Loading...

Loading...