77

107774-01- 9/17

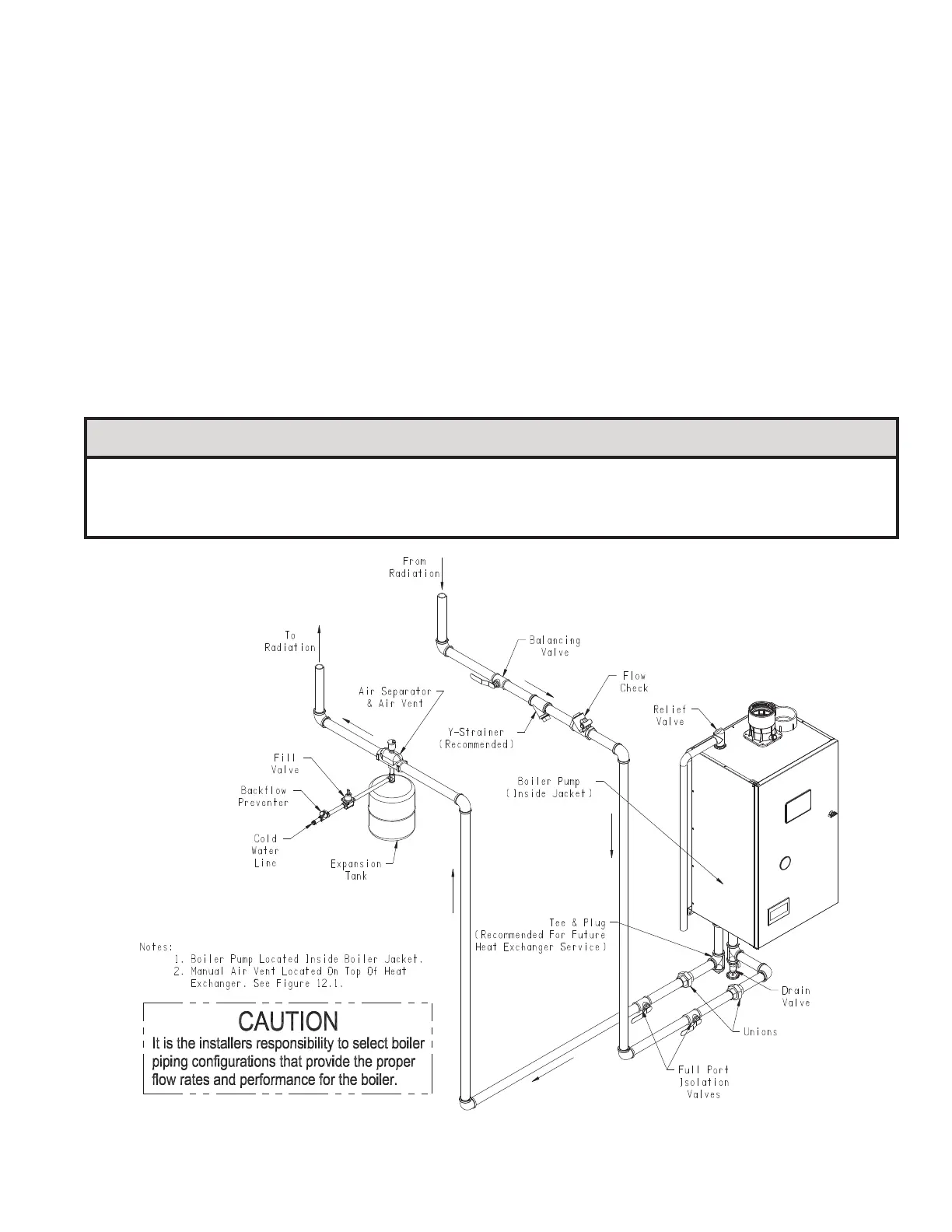

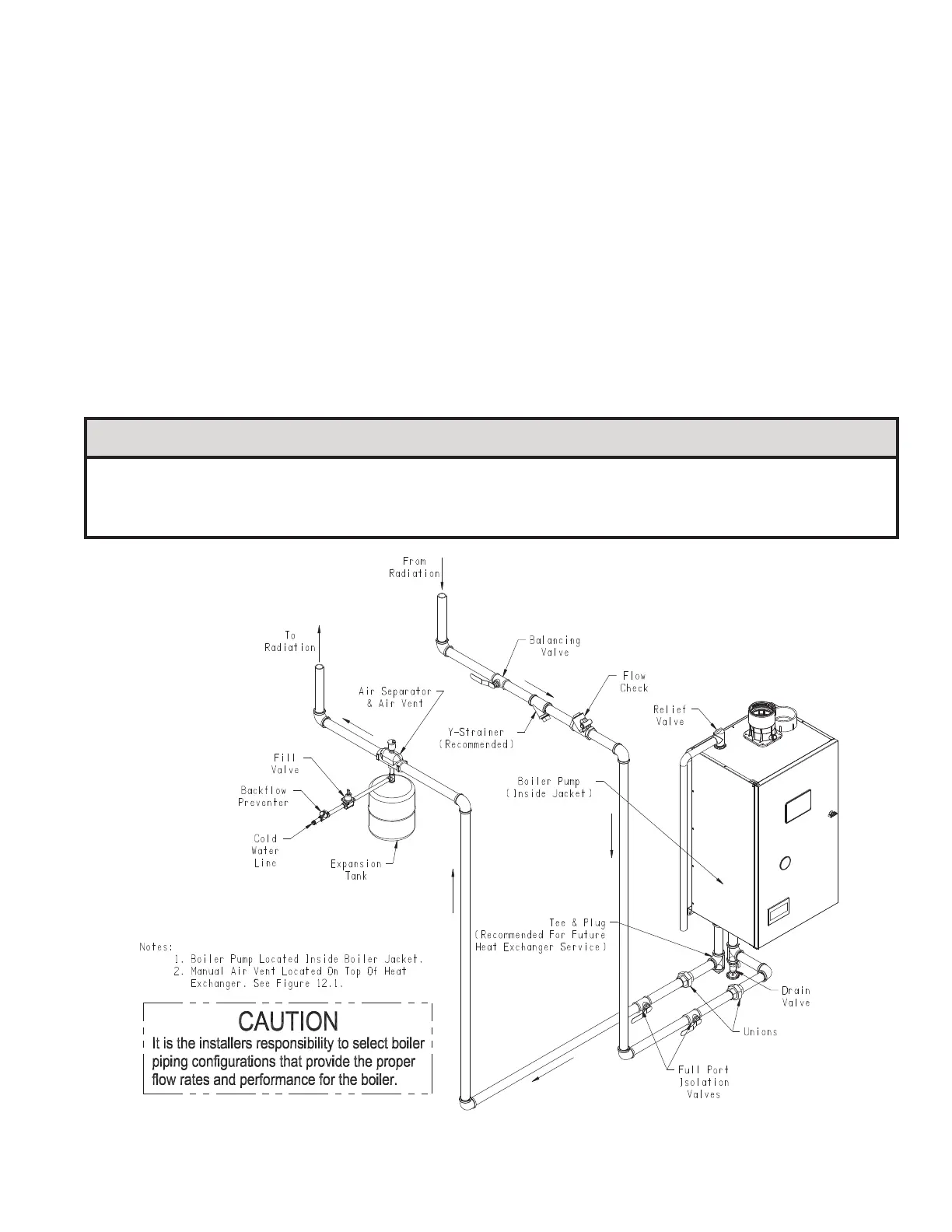

Figure 9.6: Piping Method #2 - Direct Connection of Boiler to Heating System

NOTICE

Where it is not possible to install a separate boiler loop, the system circulator must be sized to ensure that

the ow through the boiler stays within the dened parameters to prevent overheating when the boiler is

red at it’s full rated input. Install a ow meter to measure the ow, or re the boiler at full rate and ensure

the boiler delta T does not exceed 35°F (19°C).

Method 2: Direct Connection to Heating System (Generally NOT Recommended)

In some relatively rare cases it may be possible to connect this boiler directly to the heating system as is done with

conventionalboilers(Figure9.6).Ifthisisdone,theowratethroughtheboilerwillequaltheowratethroughthesystem.

TheowratethroughthesystemmustthereforealwaysremainwithinthelimitsshowninTable9.1.Forthisreason,the

pressure drop through the entire system must be known.

Thismethodisgenerallynotrecommendedbecauseitisoftenverydifculttoaccuratelycalculatethepressuredrop

through the system. In replacement installations, it may be impossible to get an accurate measurement of the amount of

pipingandnumberofttingsinthesystem.Inaddition,ifthesystemiszoned,thesystemowmaydropwellbelowthe

minimum required when only one zone is calling for heat.

The one advantage to this method is its installation simplicity. It may make sense to use this method when the boiler is to be

installed with a new single zone system having a low-pressure drop.

Figure 9.7 shows the performance curve for the pump in each boiler model, taking into account the pressure drop through

theboiler’sheatexchangerandinternalpiping.Thesecurvesthereforeshowtheowthatcanbeachievedthroughtheboiler

as a function of the pressure drop through the connected piping. Calculation of the system pressure drop must be performed

by someone having familiarity with pressure drop calculations, such as an HVAC engineer.

IX. System Piping (continued)

Loading...

Loading...