Technical Data | 10

Instruction Manual VACTEST DCC 400_EN_en 19 / 24

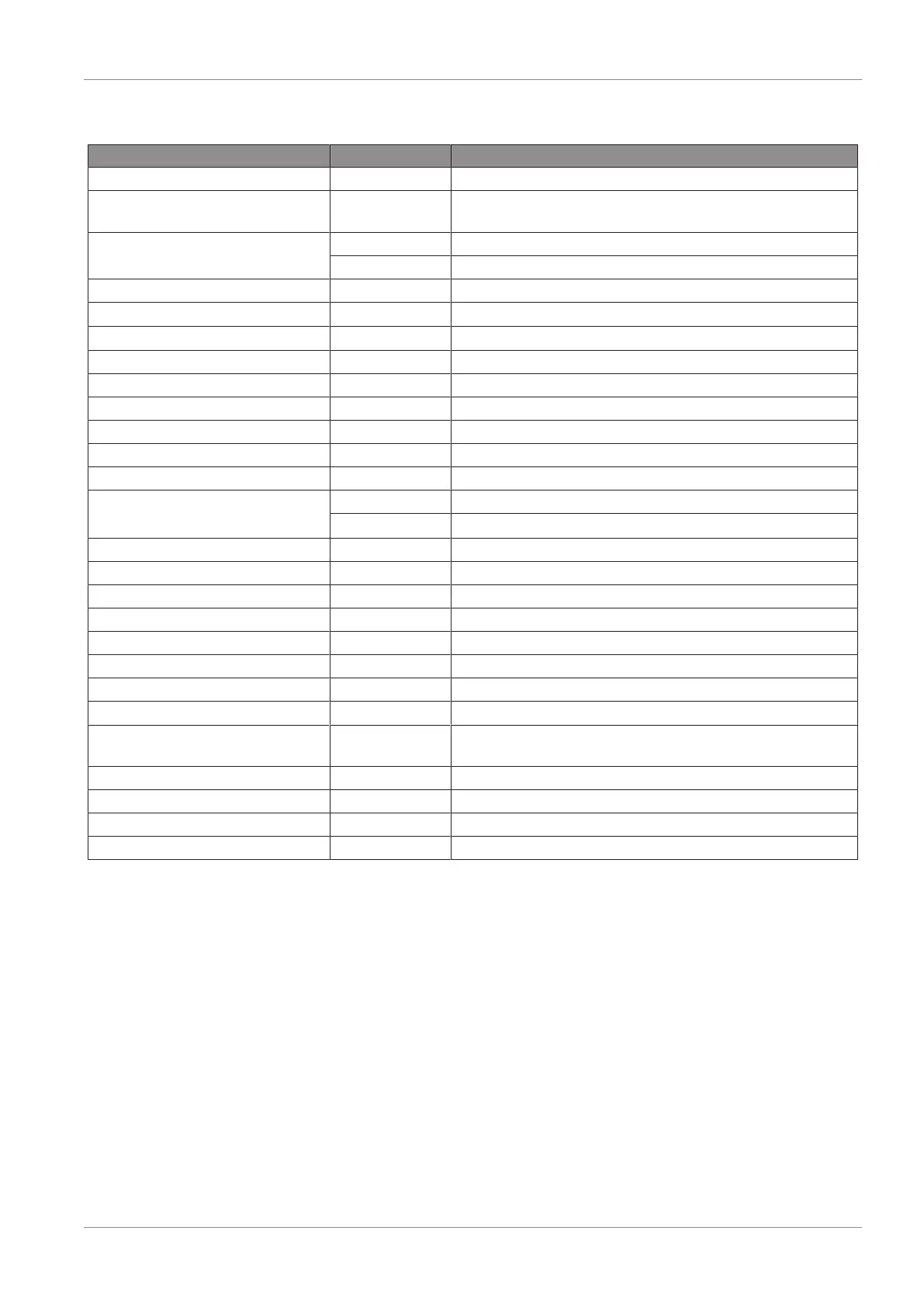

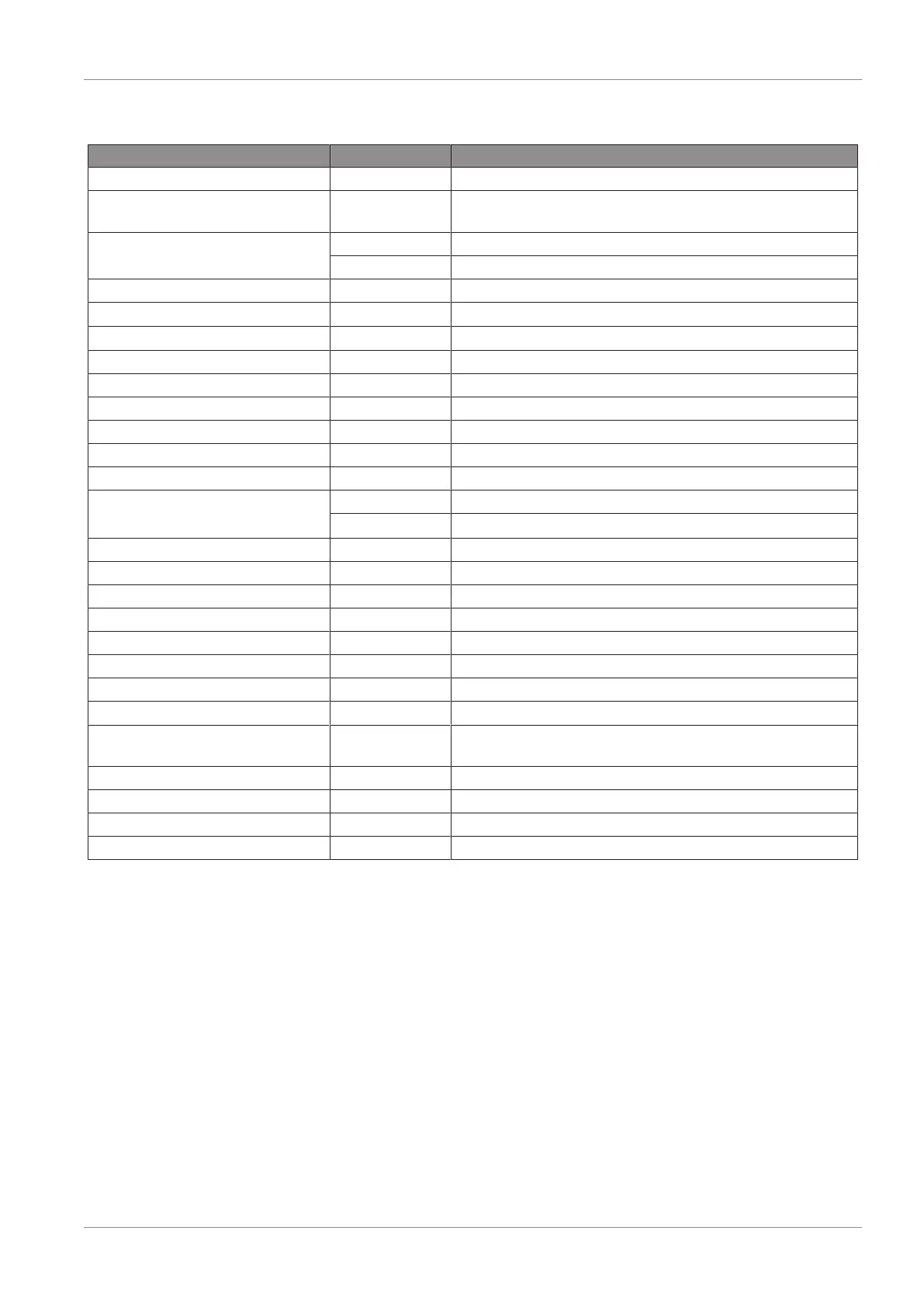

10 Technical Data

VacTest DCC 400

Measurement principle Inverted magnetron

Materials exposed to vacuum Stainless steel 1.4307, nickel, tungsten, molybdenum, glass,

ceramic

Measuring range mbar 2 x 10

-3

… 5 x 10

-9

torr 1.5 x 10

-3

… 3.75 x 10

-9

Overpressure limit bar abs. 10

Measurement uncertainty % of reading 2 x 10

-3

… 1 x 10

-8

mbar: ±25 %

Repeatability of measurement % of reading 2 x10

-3

… 1 x 10

-8

mbar: ±5 %

Leakage rate mbar l/s < 5 x 10

-10

Reaction time ms < 50

Serial Interface RS485

Electrical Connection D-Sub, 15-pin, male

Supply voltage V 20 … 30

Cathode voltage V 2.5

Max. power consumption W normal operation ► 3

W relays/display ► 0.8

Output signal 0 … 10 V, RS485

Output function V log(p

mbar

) + 10.5

Under-range voltage V 0.9

Error V 0.4

Setpoint relay 2 dry contacts

Relay contact rating 2A, 50 VAC / 2 A, 30 VDC, max. 60 VA

Operating Temperature °C +5 ... +60

Storage Temperature °C -40 ... +65

Max. bake-out temperature at the

flange

°C 160

Relative Humidity: max. 80% up to 30°C, max. 50% at 40°C, not condensing

Ambient pressure: hPa (mbar) 860 … 1060

Protection Class IP 40 (IP 54 with appropriate D-Sub connector)

Weight g 555

Loading...

Loading...