Maintenance | 7

0870169116_RH0003-0021B_-0002_IM_en 15 / 28

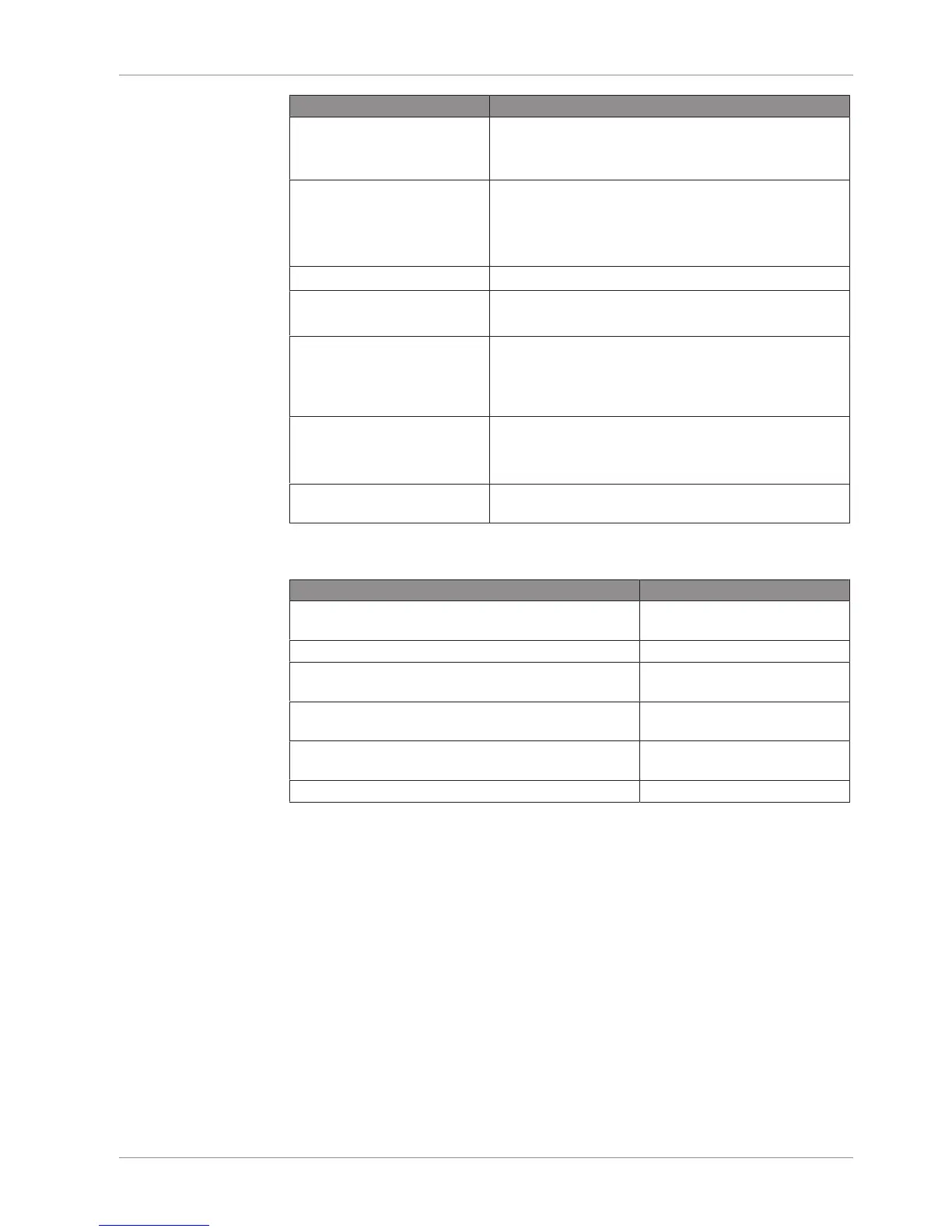

Interval Maintenance work

Weekly • Check the level and the colour of the oil.

• Check the machine for oil leaks - in case of leaks have

the machine repaired (contact Busch).

Monthly • Check the inlet screen, clean if necessary.

In case of an inlet filter being installed:

• Check the inlet filter cartridge, replace if neces-

sary.

After the first 240 hours

• Change the oil, see Oil Change [}16].

At least after 2000 hours In case of an oil separator being installed:

• Change the filter cartridge

Between 6 and 12 months

• Change the oil, see Oil Change [}16].

The oil change depends on the process application,

refer to the table of Oil Change Recommendations

[}15].

Yearly • Clean the machine from dust and dirt.

• Check the coupling, see Coupling Maintenance

[}18].

Every 5 years • Have a major overhaul on the machine (contact

Busch).

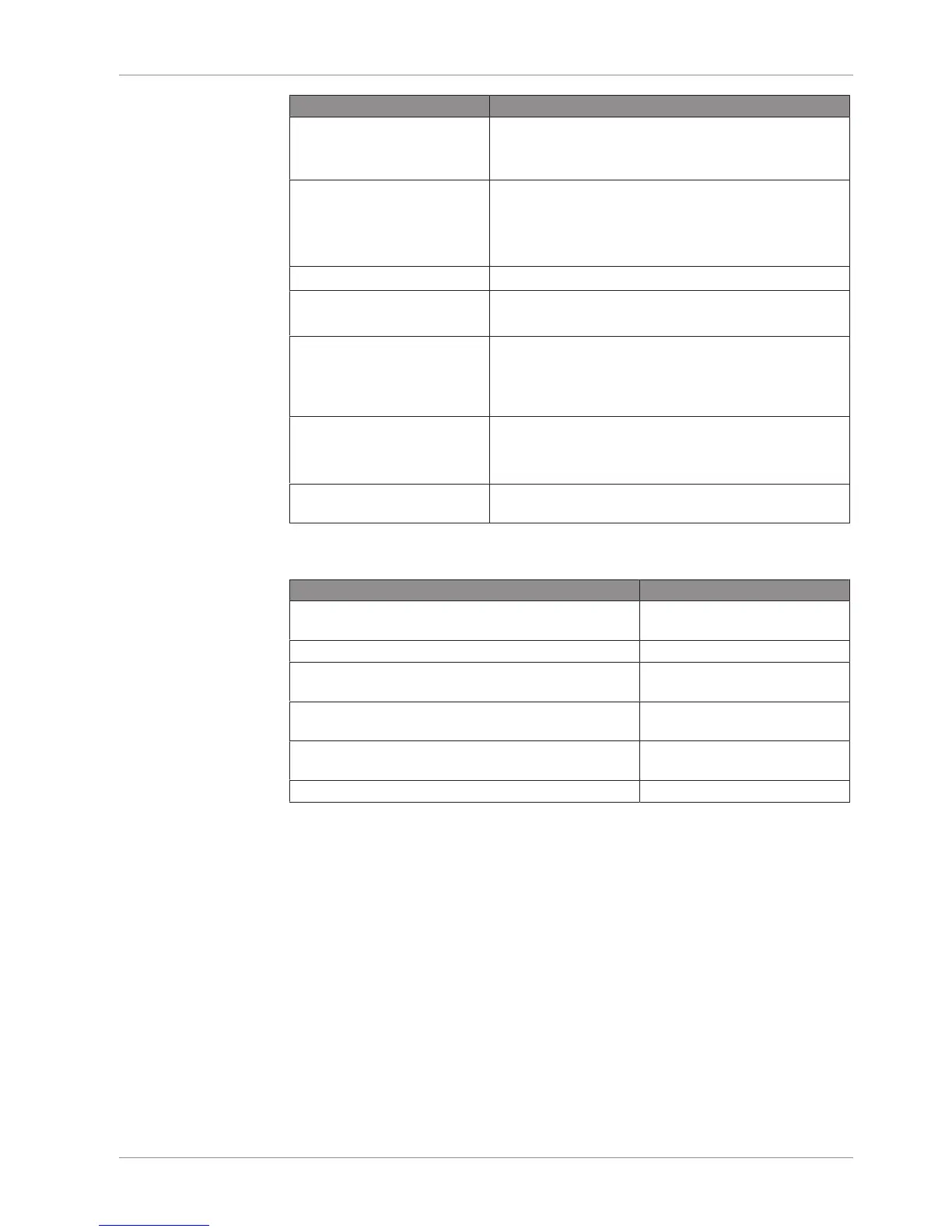

7.2 Oil Change Recommendations

Purpose Oil Change Interval

Vacuum system for study / laboratory, small vacuum

system

Within 6 months to 1 year

Vacuum system for production / vacuum evaporation Within 3 to 6 months

Vacuum valve exhaust system / large vacuum evapor-

ation system

Within 3 months

Metallurgy vacuum system such as thermal treatment,

melting and the like

Within 1 month

High vacuum dry / vacuum impregnation / vacuum

forming / vacuum packing system

Within 1 month

Low vacuum dry / pug mill / food packing system Within 1 week

Loading...

Loading...