GB

I-MAT_Ed2 - Operating Instructions Page 31 / 136

9.2.2. Constant pressure mode with 2 pressure

transducers (differential mode)

If it is required to use a differential pressure

feedback, between delivery and suction of the pump

by using 2 transducers it’s necessary to connect

the rst transducer and the second transducer as

shown in section 6.7.

Parameters to programm or check (recommended

sequence):

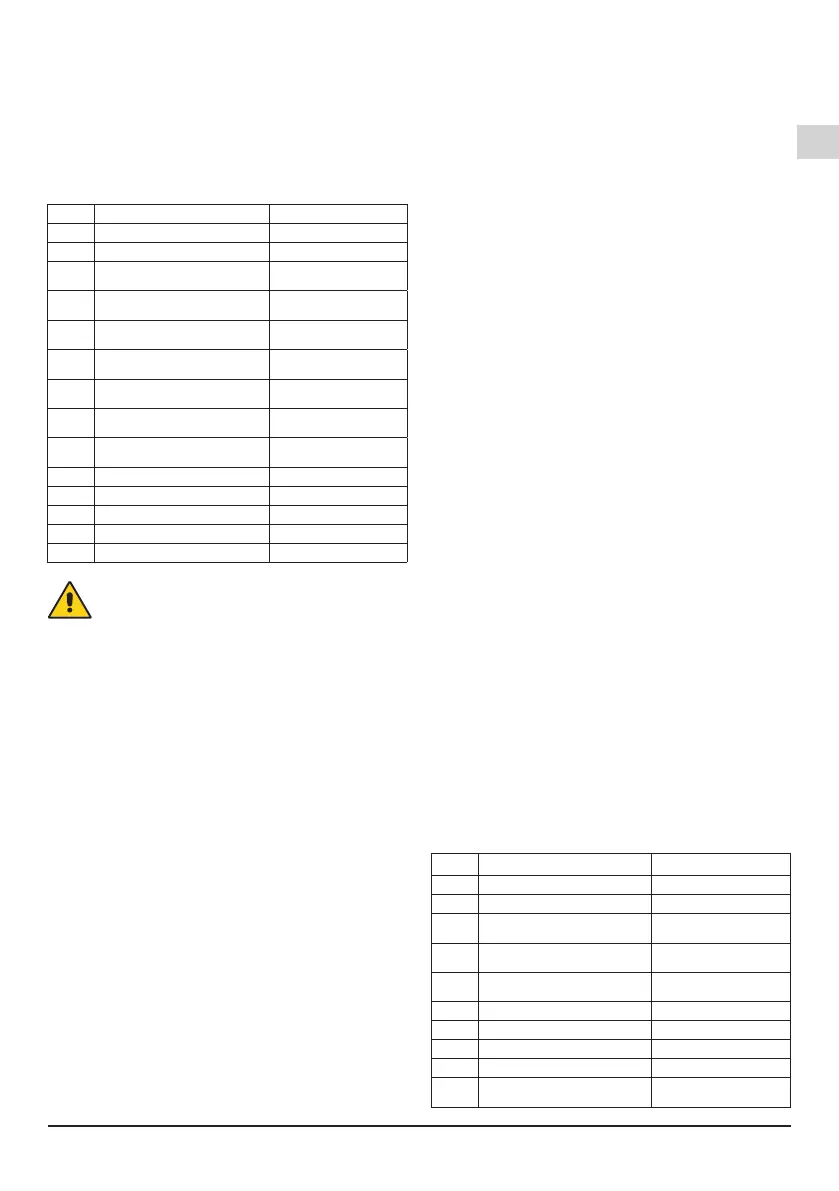

Par.

Description

Suggested value

AP01

Maximum pump pressure

based on pump type

AP02

Primary transducer supply

data sheet

transducer

AP03

Primary transducer

measuring unit

1 [bar]

AP04

Primary transducer

minimum value

data sheet

transducer

AP05

Primary transducer

maximum value

data sheet

transducer

AP06

Secondary transducer

supply

data sheet

transducer

AP07

Secondary transducer

measuring unit

1 [bar]

AP08

Secondary transducer

minimum value

data sheet

transducer

AP09

Secondary transducer

maximum value

data sheet

transducer

AP10

Secondary transducer mode

DiFF

UP02

Nominal pump current

see motor plate

UP03

Nominal pump frequency

see motor plate

UP05

Operating mode

PC

UP06

Primary set-point

on demand [bar]

To ensure the system works properly, the

primary transducer (B1-B4 clamps) must be

always connected to the delivery pipe, and

the secondary transducer (B5-B8 clamps)

must be always connected to the suction

pipe.

9.2.3. Minimum run frequency and pre-pause

frequency settings

The frequency converter is equipped with an

automatic stop system in case of low water. In

the case where the system does not guarantee

the correct stop of the pump, it is possible to set

manually the following values:

Frequency before stop

Minimum run frequency

In order to manually set these parameters it is

necessary to change the value of parameter AP17

from “Auto” to “Man”. Then the pre-pause frequency

values (PC02 and PC04 parameters) and the

minimum frequency values (PC01 and PC03

parameters), must be set using the calculation

formulas described in the next section.

9.2.4. Frequency before stop and minimum run

frequency calculation formulas

Adjusting the pre-pause frequency (PC02 and

PC04 parameters) allows you to properly stop the

pump when the water demand is low and the pump

operation is no longer required (e.g. a leakage or a

small ow of a few liter per minute).

In this case the pump must be stopped for some

seconds and the ow is guaranteed by the reserve

stored in the vessel.

The frequency before stop Hz P can be calculated

as follows:

50 Hz pumps

Hz=2+ √(Hset÷Hmax )x 50 (*)

60 Hz pumps

Hz=2+ √(Hset÷Hmax )x 60 (*)

where: - H set is the working pressure in bar

- H max is the maximum pump pressure, in

bar, when ow is equal to 0.

(*) For the maximum pump pressure it’s required:

For the pumps operating with suction lift subtract

the suction lift value (in bar).

For the pumps installed with suction positive add

the positive suction head value (in bar).

The minimum run frequency (PC01 and PC03

parameters) must be set 6-7 Hz lower than the

frequency before stop.

9.3. Proportional pressure mode

The proportional pressure operating mode reduce

the pressure proportionally with the water demand

of the system.

In this operating mode the frequency converter

keeps a set-point pressure at the maximum

frequency, this set-point pressure could be set with

the parameter UP06.

The slope of the pressure-ow rate line could be set

through the percentage of the pressure when ow

is equal to 0.

It is possible to have different congurations of this

operating mode related with the different types and

number of transducers installed:

Proportional pressure with 1 pressure transducer

(absolute or differential transducer).

Proportional pressure with 2 pressure transducers

in differential mode.

For detailed program settings see the following

conguration sections.

9.3.1. Proportional pressure mode with single

transducer (differential or absolute)

This conguration uses a feedback given by a

pressure transducer (connected as shown in

section 6.7).

Parameters to programm or check (recommended

sequence):

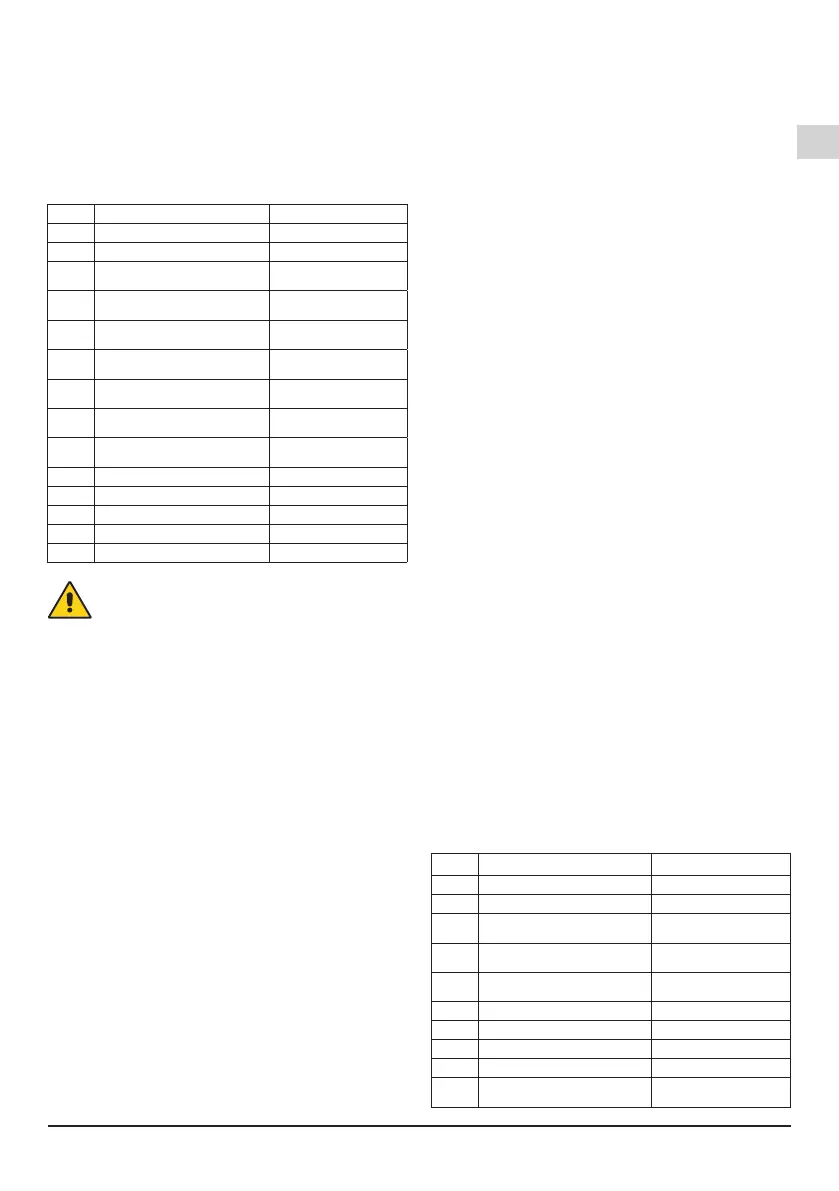

Par.

Description

Suggested value

AP01

Maximum pump pressure

based on pump type

AP02

Primary transducer supply

data sheet

transducer

AP03

Primary transducer

measuring unit

1 [bar]

AP04

Primary transducer

minimum value

data sheet

transducer

AP05

Primary transducer

maximum value

data sheet

transducer

UP02

Nominal pump current

see motor plate

UP03

Nominal pump frequency

see motor plate

UP05

Operating mode

PP

UP06

Primary set-point

on demand [bar]

PP01

Percentage of the pressure

with zero ow

50 [%]

Loading...

Loading...