GB

I-MAT_Ed2 - Operating Instructions Page 43 / 136

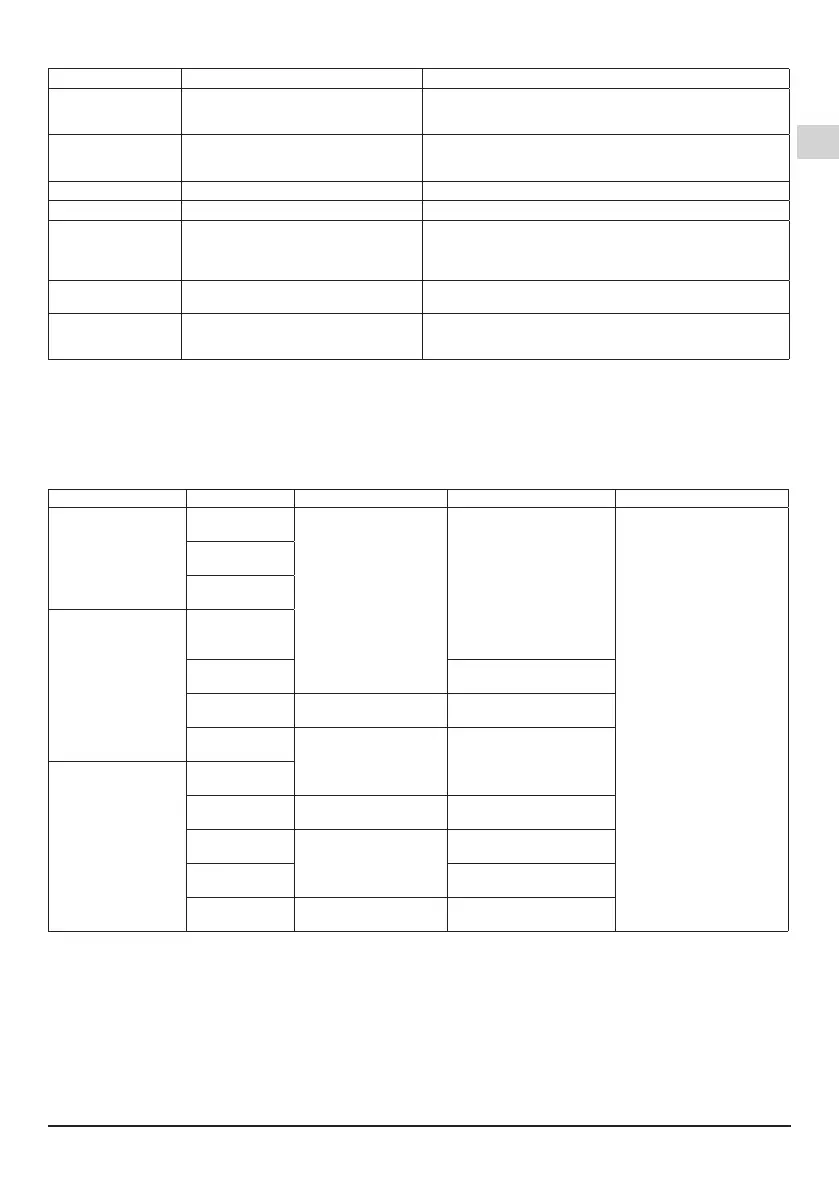

18. Troubleshooting chart

Fault Probable cause Possible solution

Short-circuit - Motor or cable short-circuit

- Wrong power supply connection

- Wrong connection of the cable shield

- Check motor connections

- Check power supply voltage

Frequency

converter

overheating

- Ambient temperature too high

- One or more frequency converter fans

faulty

- Check the condition of installation (see section 3.1)

- Change the defective fans

Low supply voltage - Supply voltage lower than 330V - Check the supply line

High supply voltage - Supply voltage higher than 520V - Check the supply line

Overcurrent - Step up/down ramp too high

- Improper connection of the motor

- Wrong motor settings

- Increase the time of the ramps (see section 16.2)

- Check the parameters of the motor (see section 16.1)

- Check the frequency converter settings and motor data (see

section 16.1)

Electronic card

overheating

Electronic card overheating - Check the condition of installation (see section 3.1)

- Reduce the carrier frequency

Dry-run The pump is running with no water - Check the suction and delivery manifold and the priming

conditions

- Check the performances curves of the pump

1) For electrical reparation, disconnect the supply voltage from the frequency converter. Refer to the safety

regulation described in section 4.

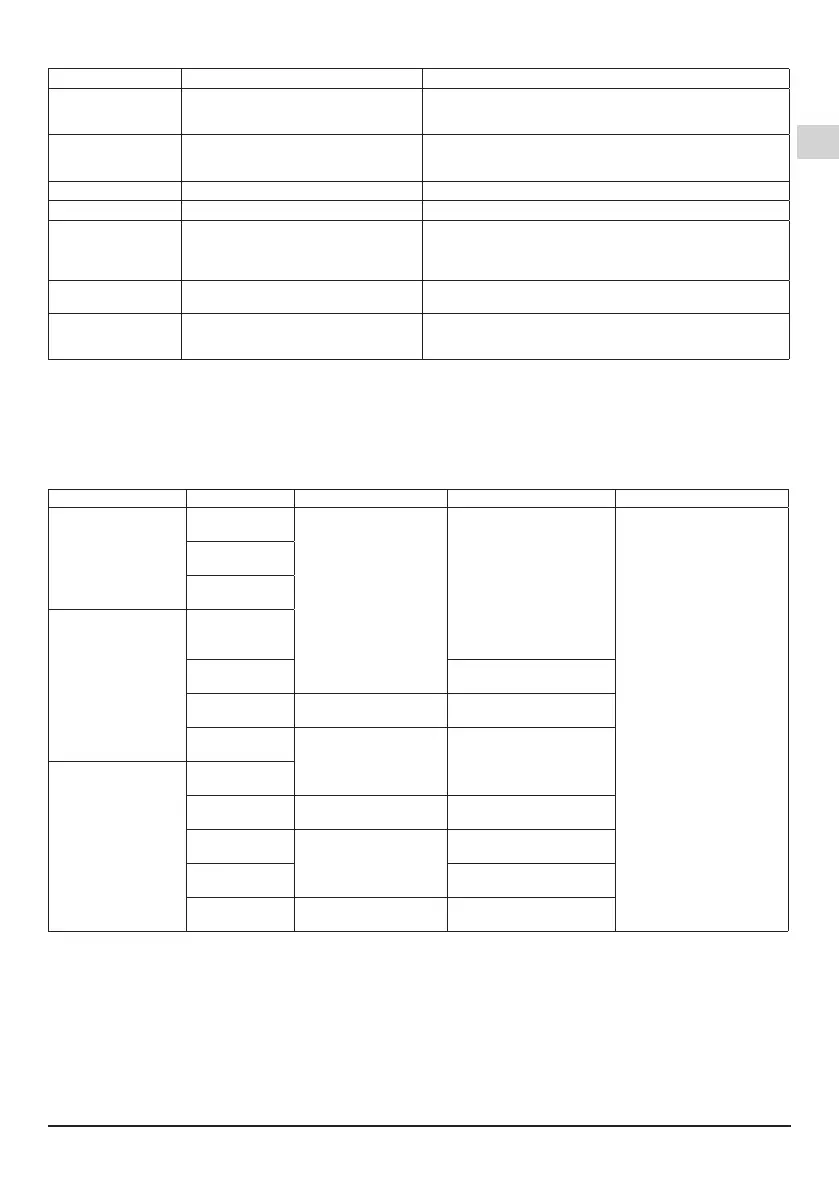

19. Filters for the reduction of irradiated noise and electromagnetic noise emissions

I-MAT Inom (A) Filter Sinusoidal lter Maximum length

I-MAT 5.2TT-A

0.1 - 2

CNW 854/8

CNW 933/6

No length limit

2 - 4

4 – 5.2

I-MAT 11.2TT-B

5.3 - 6

6 - 8

CNW 933/8

8 - 10 CNW 854/10 CNW 933/10

10 – 11.2

CNW 854/12 CNW 933/12

I-MAT 25.8TT-C

11.3 - 12

12 - 16 CNW 854/16 CNW 933/16

16 - 20

CNW 854/24

CNW 933/20

20 - 24 CNW 933/24

24 - 30 CNW 854/30 CNW 933/30

Loading...

Loading...