54

Section 2 Scanner

®

2000 microEFM

Measuring Uncompensated Liquid via a Turbine Meter

Best Practices

7KH6FDQQHUPLFUR()0FDOFXODWHVXQFRPSHQVDWHGOLTXLGÀRZWKURXJKDWXUELQHPHWHULQDFFRUGDQFH

ZLWK$3,0306&KDSWHU6HFWLRQ0HDVXUHPHQWRI/LTXLG+\GURFDUERQVE\7XUELQH0HWHUV)RU

optimum performance, ensure that the turbine and Scanner 2000 installation complies with the industry

UHFRPPHQGDWLRQVOLVWHGEHORZ

,QVWDOOWKHWXUELQHÀRZPHWHULQWKHPHWHUUXQVXFKWKDWWKHUHDUHDWOHDVWQRPLQDOSLSHGLDPHWHUVXS-

VWUHDPDQG¿YHQRPLQDOSLSHGLDPHWHUVGRZQVWUHDPRIWKHPHWHU%RWKLQOHWDQGRXWOHWSLSHVKRXOGEHRI

WKHVDPHQRPLQDOVL]HDVWKHPHWHU

6WUDLJKWHQLQJYDQHVDUHUHFRPPHQGHGIRUHOLPLQDWLQJVZLUOFRQGLWLRQV,IXVHGWKH\VKRXOGEHLQVWDOOHG

¿YHSLSHGLDPHWHUVXSVWUHDPRIWKHPHWHU

Installation Procedure—Direct Mount to a Turbine Meter (CSA Compliant)

A Scanner 2000 without the MVT bottomworks can be mounted directly to a liquid turbine meter for

PHDVXULQJOLTXLG)LJXUH$SLSHDGDSWHUDQGXQLRQDUHDWWDFKHGWRWKH6FDQQHUDOORZLQJDGLUHFW

FRQQHFWLRQWRWKHWXUELQHPHWHU

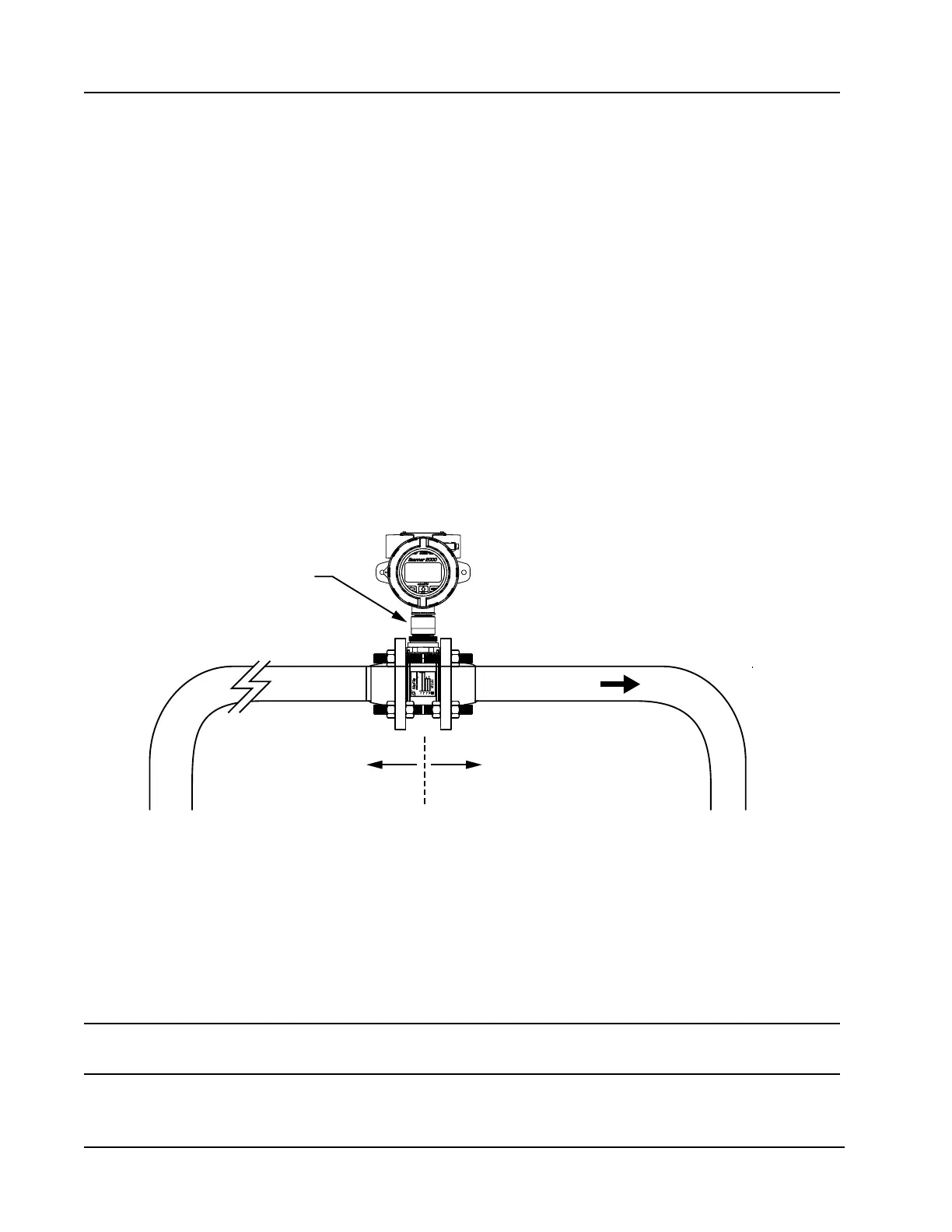

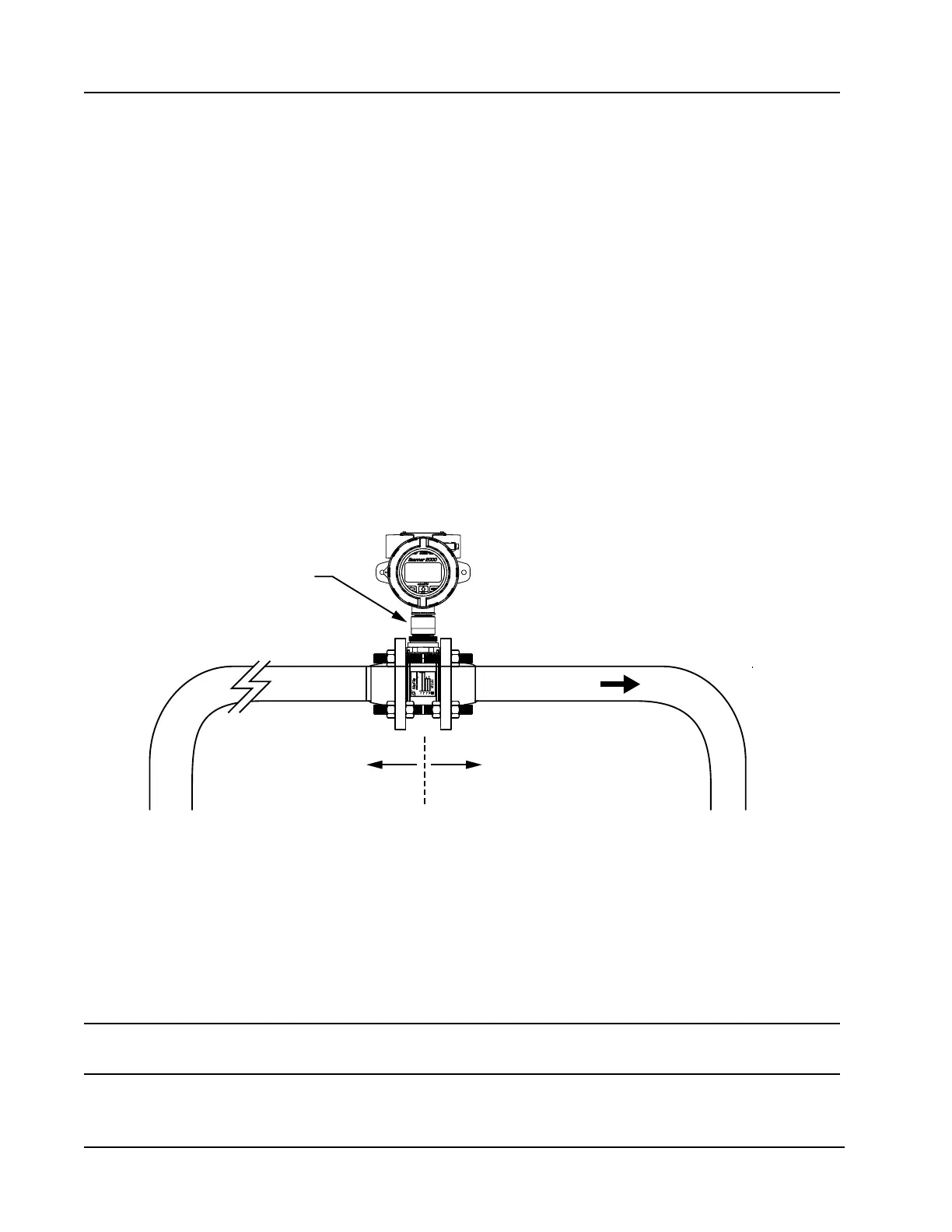

Flow

Adapter/union

(CSA-approved)

10 pipe diameters

upstream (minimum)

5 pipe diameters

downstream (minimum)

Figure 2.14—Direct-mount installation for use with a Barton 7000 Series meter

7RFRQQHFWWKH6FDQQHUWRDOLTXLGWXUELQHPHWHUXVLQJWKLVPHWKRGSHUIRUPWKHIROORZLQJVWHSV

3RVLWLRQWKH6FDQQHUDERYHWKHÀRZPHWHU

3OXJWKH6FDQQHUFDEOHFRQQHFWRULQWRWKHPDJQHWLFSLFNXSRIWKHWXUELQHPHWHUDQGKDQGWLJKWHQWKH

NQXUOHGQXWRQWKHFRQQHFWRU

6FUHZWKH6FDQQHURQWRWKHÀRZPHWHUWKUHDGVVXUURXQGLQJWKHPDJQHWLFSLFNXSZLWKWKHGLVSOD\IDF-

LQJWKHGHVLUHGGLUHFWLRQ

&$87,21 'RQRWXVH7HÀRQ

®

WDSHRQWKHWKUHDGVRIWKHXQLRQDGDSWHURUSLSHSOXJV8VHRI

7HÀRQ

®

tape will void the explosion-proof rating of the instrument.

7LJKWHQDOOVHFWLRQVRIWKHSLSHXQLRQ

Loading...

Loading...