Gas burning appliances are divided into four categories based

on the pressure and temperature produced in the exhaust stack

and the likelihood of condensate production in the vent.

Category I. An appliance operating with a non-positive vent

static pressure and with a vent gas temperature that avoids

excessive condensate production in the vent (i.e. “B Vent”).

Category II. An appliance operating with a non-positive vent

static pressure and with a vent gas temperature that may

cause excessive condensate production in the vent.

Category III. An appliance operating with a positive vent

pressure and with a vent gas temperature that avoids

excessive condensate production in the vent.

Category IV. An appliance operating with a positive vent

pressure and with a vent gas temperature that may cause

excessive condensate production in the vent (i.e. “BH Special

Gas Vent”).

The VTech water heater can be vented as either a Category II or

IV appliance. It must be vented and supplied with combustion

and ventilation air as described in this section. Provisions for

combustion and ventilation air are to be in accordance with the

section “Air for Combustion and Installation”, of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or clause 8.2, 8.3, 8.4

of “Natural Gas and Propane Installation Code”, CSA

B149.1-15 and CSA B149.2-15, or appliance provisions of the

local building codes. The distance of the vent terminal from

adjacent buildings, windows that open and building openings

must comply with the latest edition of the National Fuel Gas

Code, ANSI Z223.1. In Canada, the installation and clearances

must comply with the latest edition of CSA B149.1-15 and CSA

B149.2-15 Installation Code for Gas Burning Appliances and

Equipment.

For indoor installations, venting must be in accordance with Part

7 “Venting of Equipment” of the National Fuel Gas Code,

ANSI Z223.1, or Section 7 “Venting of Equipment and Air

Supply for Appliances” of the CSA B149.1-15 and CSA

B149.2-15 installation code, or applicable provisions of the local

building codes. Horizontal runs of vent pipe shall be securely

supported (approximately every 4 feet) to prevent sagging and

maintain a minimum slope of ¼" per foot to provide drainage of

the vent towards the nearest drain or the vent termination.

The weight of the venting system must not rest on the unit.

Adequate support of the venting system must be provided in

compliance with local codes and other applicable codes. Vent

connection is made directly to the flue outlet opening on the back

of the unit. All connections should be secured and sealed per the

vent manufacturers specifications. When a positive vent system

is disconnected for any reason, the flue must be reassembled

and resealed according to the vent manufacturer’s instructions.

Do not use an existing chimney as a raceway if another appliance

or fireplace is vented through the chimney.

3.1.1 – Venting Transition

All VTech have a round stainless steel vent connection suitable

for direct connection to PVC or CPVC piping, of the size listed in

Section 1.3.3.

Adaptors for stainless steel venting are available from CAMUS.

Polypropylene vent adaptors are available from the venting

manufacturer directly.

Depending on the venting category chosen and the design

provide by the vent manufacturer, an increaser may be required

for the proper vent configuration.

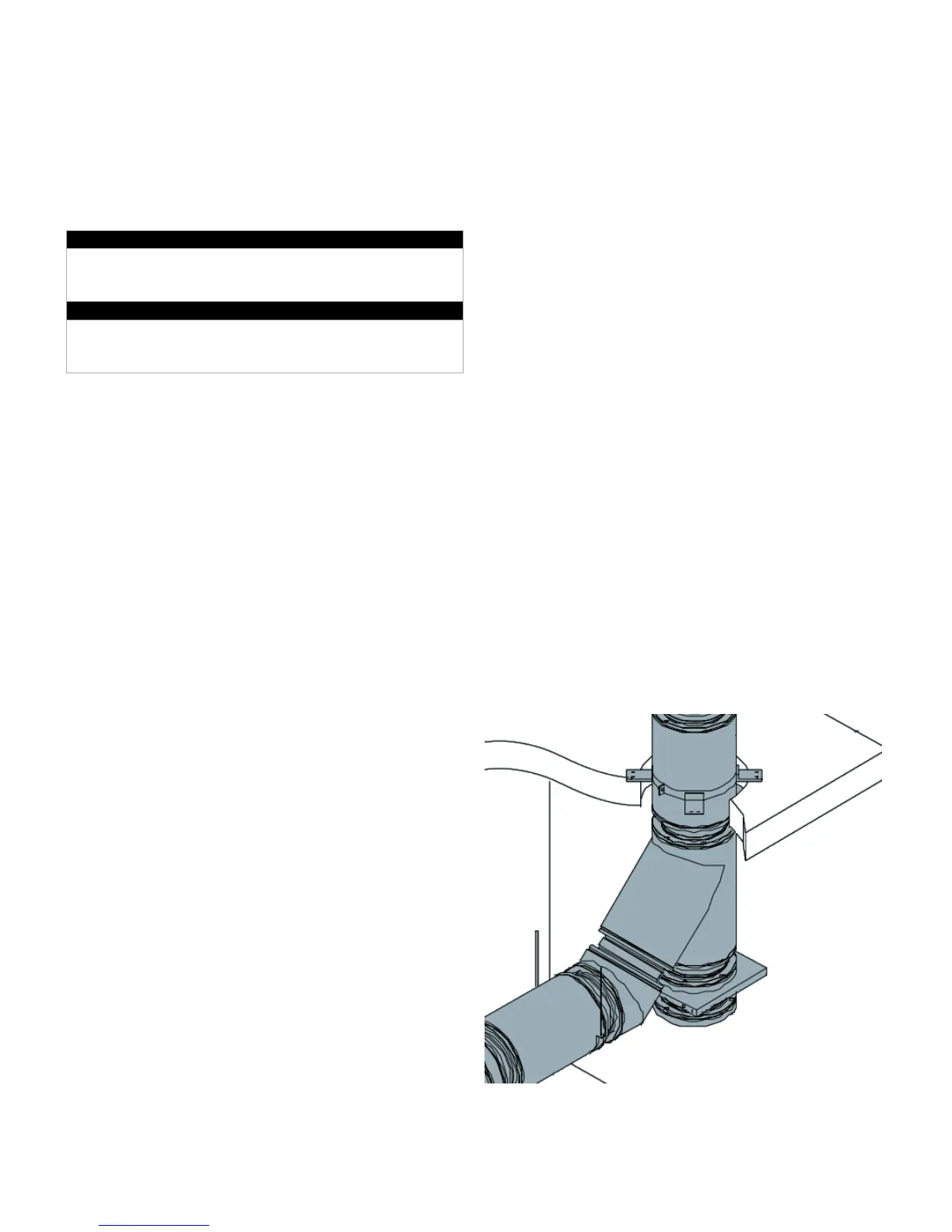

3.1.2 – Vent Drainage

Care must be taken to properly seal all joints against leakage of

exhaust or condensate. All horizontal runs should be provided

with a slope or ¼” per linear foot to ensure efficient drainage of

condensate. This slope should be designed to take condensate

away from the water heater, and towards the nearest vent drain.

The bottom of any vertical vent run should have a combination

45° tee/elbow with drain cap installed to remove condensate in

this area of the vent. If this vertical run includes several horizontal

or angled offsets, all components must be arranged to provide a

continuous downward slope to the tee at the base of the run.

Horizontal sections from this tee must be sloped away, either to

the next tee in the system, or back to the water heater.

NOTE: Any drain in the venting system will require a trap to

ensure flue gas does not enter the interior space.

Combination Tee and Elbow, w/ Drain Cap

In systems where the vent remains horizontal after the initial

vertical rise from the water heater vent connection, it should be

sloped to drain through the sidewall. In cases where the

Loading...

Loading...