8

condensate cannot be drained outside, a horizontal drain section

should be installed in the venting before penetrating the sidewall.

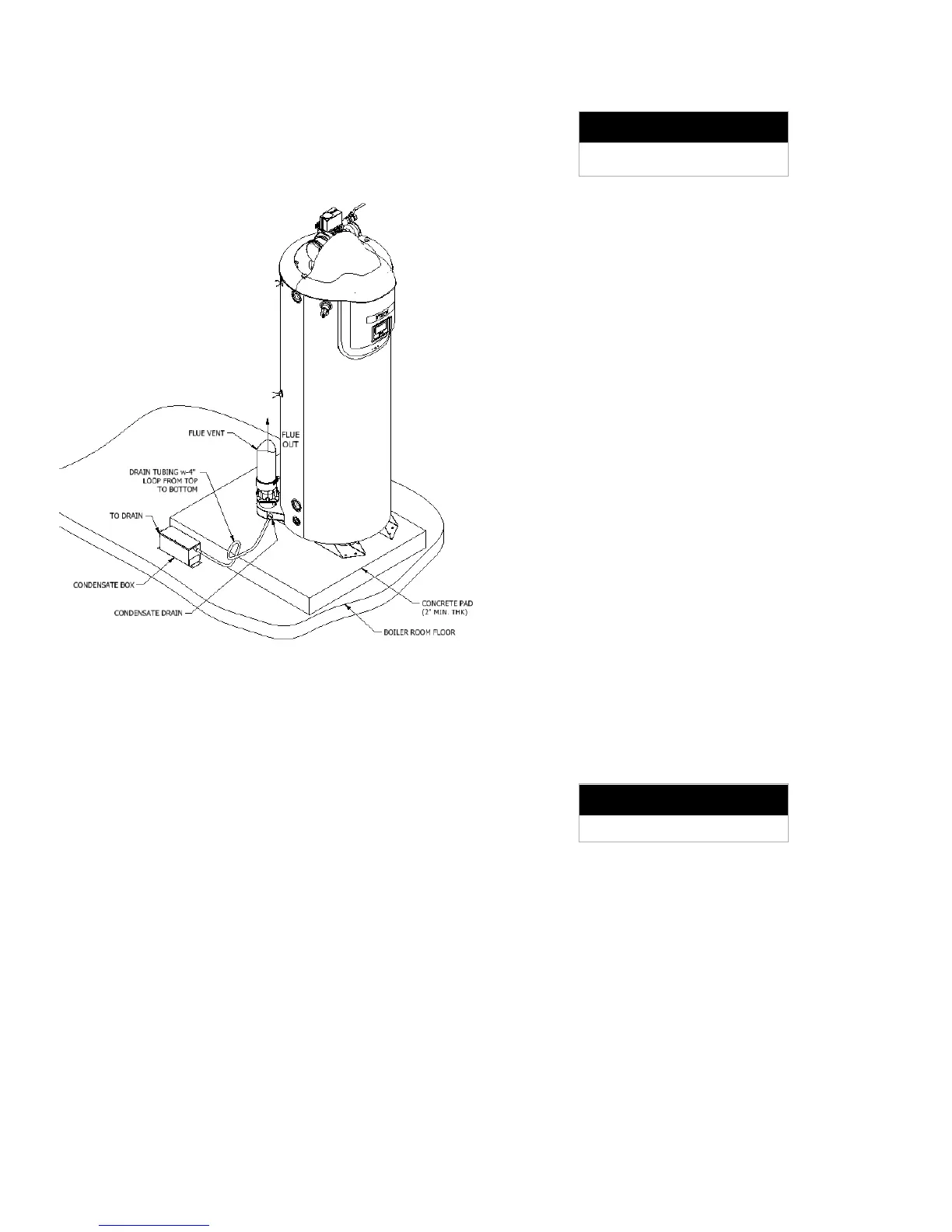

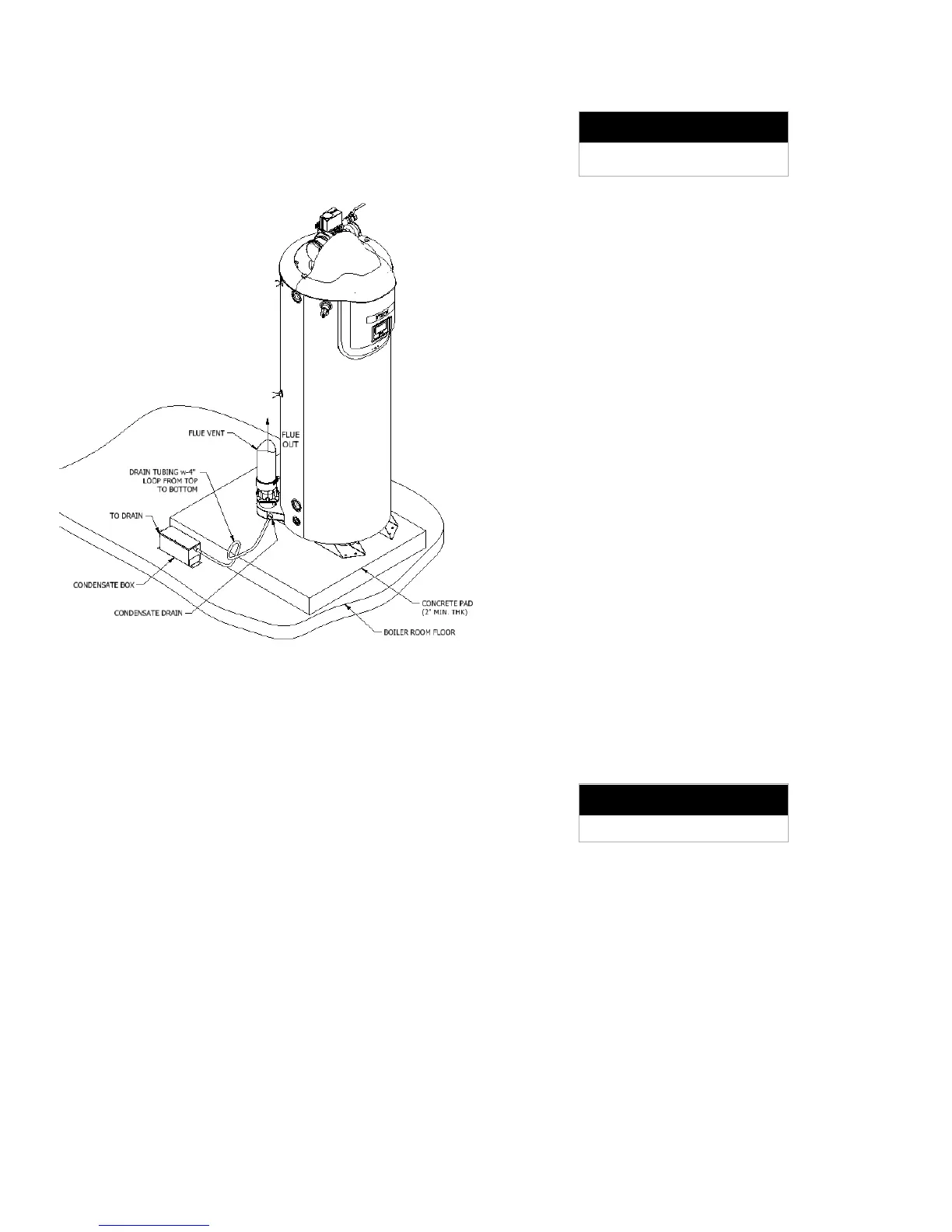

The water heater connects directly to a vertical vent run and does

not require a base tee. A drain line must be connected to the

water heater to collect and dispose of condensate.

Drain and Neutralizer Cartridge Installation

Plastic drain tubing shall be provided as a drain line for the water

heater condensate drain. The tubing must have a trap (a 4"

(10cm) diameter circular trap loop in the drain tubing is sufficient).

Prime the trap loop by pouring a small quantity of water into the

drain hose before assembly to the water heater connection. Use

caution not to collapse or restrict the condensate drain line. The

drain must be routed to the condensate neutralization system or

a suitable drain for disposal of condensate that occurs in both the

water heater and in the vent system. Ensure that the drain from

the condensate tee is not exposed to freezing temperature.

3.1.3 – CAT II Venting

A Category II venting system operates with a negative pressure

in the vent at all times, and with flue gas temperatures

sufficiently cool for condensation to occur before reaching the

termination. As a result, a corrosion resistant stainless steel,

such as AL29-4C or 316L, must be used for the venting. AL29-

4C is typically recommended for having higher corrosion

resistance. (This recommendation does not supersede local

codes or the provisions of CSA B149.1-15 and CSA B149.2-

15 in Canada or the National Fuel Gas Code in the United

States.) 316L is limited to use in applications where there is no

possibility of contaminants in the air such as refrigerants, chlorine

etc. Always choose the venting system which best satisfies the

requirements of the application.

The Category II vent systems can be used for single appliances,

but they can also be used to vent multiple appliances combined

into a common vent. This special venting system must be

engineered by a venting manufacturer or other qualified

professional, using a proven vent-sizing program with

knowledge of accurate operating parameters. Approval of the

installation is at the discretion of the authority having jurisdiction.

Acceptable Breech Pressure

For CAT. II Vent Systems

For Category II vent systems, the pressure at the appliance

breeching must be kept within a range of ˗0.05” WC to ˗0.15”

WC. If the calculated draft at any unit exceeds this range (i.e. ≤

˗0.16” WC), a single acting barometric damper, or suitable

alternative draft control approved by the vent designer or

engineer, must be used to prevent the extra suction from

decreasing the pressure at the breeching.

If the vent cannot support a negative draft under all conditions,

and a positive pressure will be developed during some operation,

then the vent design must be changed accordingly. Possible

options include changing the design to Category IV, or providing

an extractor (or “draft inducer”) at the vent outlet, interlocked with

the appliance operating circuit, in order to maintain a negative

draft in the vent while the unit is operating. The designer must

ensure that the solution utilized will maintain the vent system at

the desired minimum draft under all conditions.

Category II vents typically terminate vertically through the roof.

The flue from a Category II vent system must have a condensate

drain with provisions to properly collect, neutralize and dispose

of any condensate that may occur.

3.1.4 – CAT IV Venting

The Category IV venting system operates with positive pressure

at the appliance breeching generated by the combustion air fan,

which operates the combustion process and also exhausts the

flue products from the building. The pressure may be positive

throughout, though it is conceivable to operate with negative

pressure in part of a Category IV vent system. In either case, the

entire Category IV vent system must have all joints and seams

sealed gas-tight. The flue products in the vent system will be

cooled below their dew point and form condensate, so Category

IV systems must use AL29-4C or 316L stainless steel, or

approved thermoplastics like UL/ULC S636 PVC or CPVC, and

polypropylene (PPE, to maximum 12” diameter).

Acceptable Breech Pressure

For CAT. IV Vent Systems

The installed length of the positive pressure Category IV vent,

from the appliance to the point of termination outside of the

building, must not exceed a maximum of 100 equivalent feet

(30.5M) in length. The straight length that each elbow equates

to depending on the diameter and centerline radius, typically 7 to

19 feet per 90° elbow and roughly half this value for each 45°

elbow. The equivalency values must be verified with the

individual vent manufacturer, as they are not standard, and

depend on the precise dimensions, surface roughness, etc., that

a particular product is built with. For site conditions exceeding

100 equivalent feet an engineered vent system approved by the

local authority will be required.

Category IV vents may terminate either vertically through the

roof, or horizontally on a side wall. See the information about the

specific vent termination location for recommended location and

clearances. The flue from a Category IV vent system must have

a condensate drain with provisions to properly collect, neutralize

and dispose of any condensate that may occur.

Loading...

Loading...