19

Part 5 – Water

5.1 – Installation Guidelines

The Tank is comprised of vertical tubes welded directly into a

stainless steel combustion chamber. This assembly is contained

in a pressure vessel, incorporating a storage volume to

accommodate “dump” loads. This Tank is designed to withstand

160 PSIG working pressure.

Check all applicable local plumbing and building safety codes

before proceeding. If the appliance is installed above the system

it may require a low water cut-off device at the time of appliance

installation (available from factory). Some local codes require the

installation of a low water cut-off on all systems.

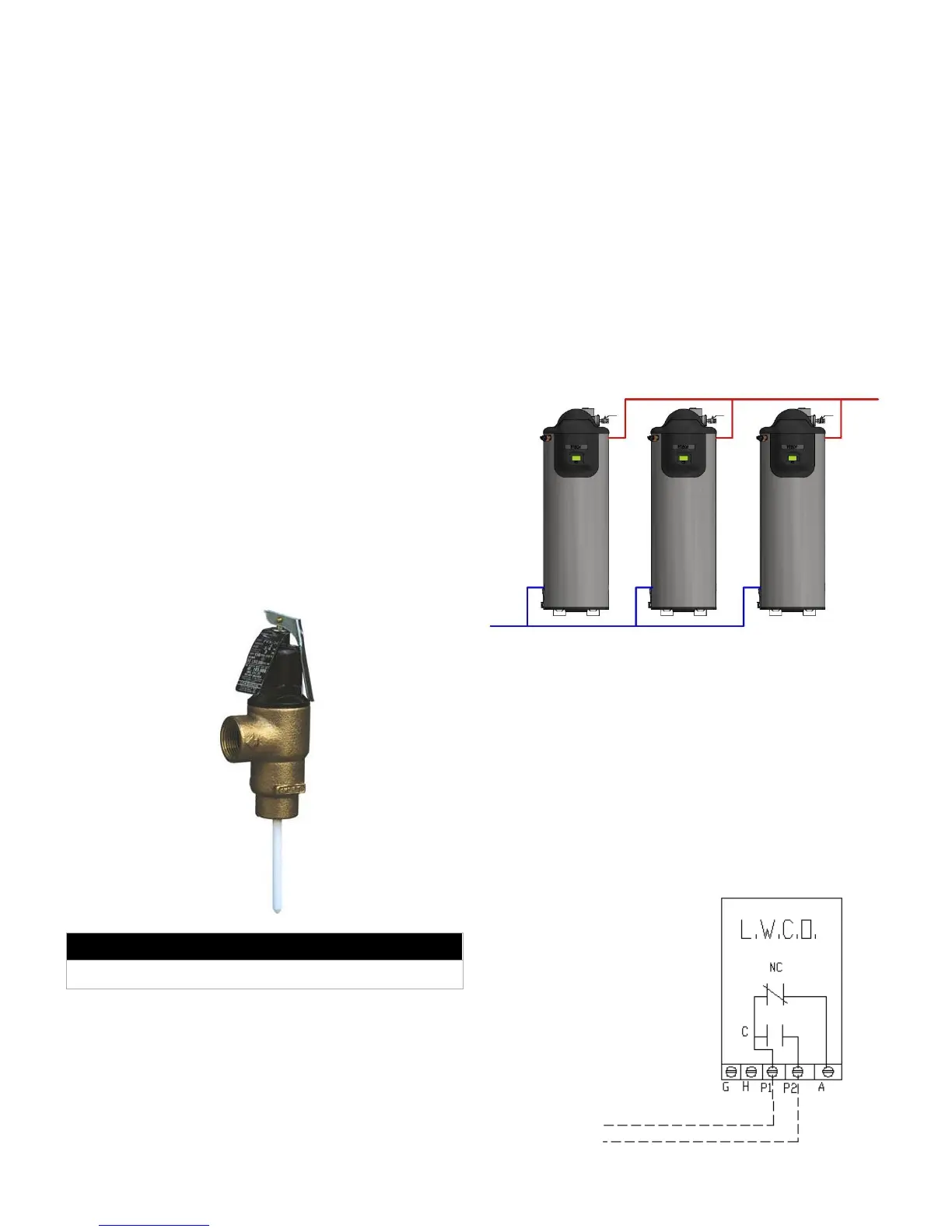

This appliance is supplied with a temperature and pressure

relief valve sized in accordance with ASME Water Heater and

Pressure Vessel Code, Section IV. The relief valve is installed

in the side of the pressure vessel near the top of the appliance.

To prevent water damage, the discharge from the relief valve

shall be piped to a suitable floor drain for disposal when relief

occurs. No reducing couplings or other restrictions shall be

installed in the discharge line. The discharge line shall allow

complete drainage of the valve and line. Relief valves should be

manually operated at least once a year. If a relief valve

discharges periodically, this may be due to thermal expansion in

a closed water supply system. Contact the water supplier or local

plumbing inspector on how to correct this situation. Do not plug

the relief valve.

T&P Relief Valve

NOTE: If the water heaters are used for charging a large storage

tank and installed with a pump circulating water between the tank

and this appliance, then an expansion tank connected to this loop

becomes the “Point of No Pressure Change”, since the pressure

at this point will remain constant regardless of pump operation.

In this case always pump away from the expansion tank

connection and into the VTech inlet connection. Pumping away

from the expansion tank means that the pressure on the suction

side of the pump is dissipated at the expansion tank, allowing the

pump differential to add pressure to the system, enhancing

system performance.

5.2 – Connecting to the Tank

All water connections are FNPT fittings. For ease of service,

install unions on the inlet and outlet of the appliance. The

incoming cold water must be connected to the lower port

connections on either the left or right side of the appliance. The

hot water supply to the building must be connected to the upper

port connections on either the left or right side of the appliance.

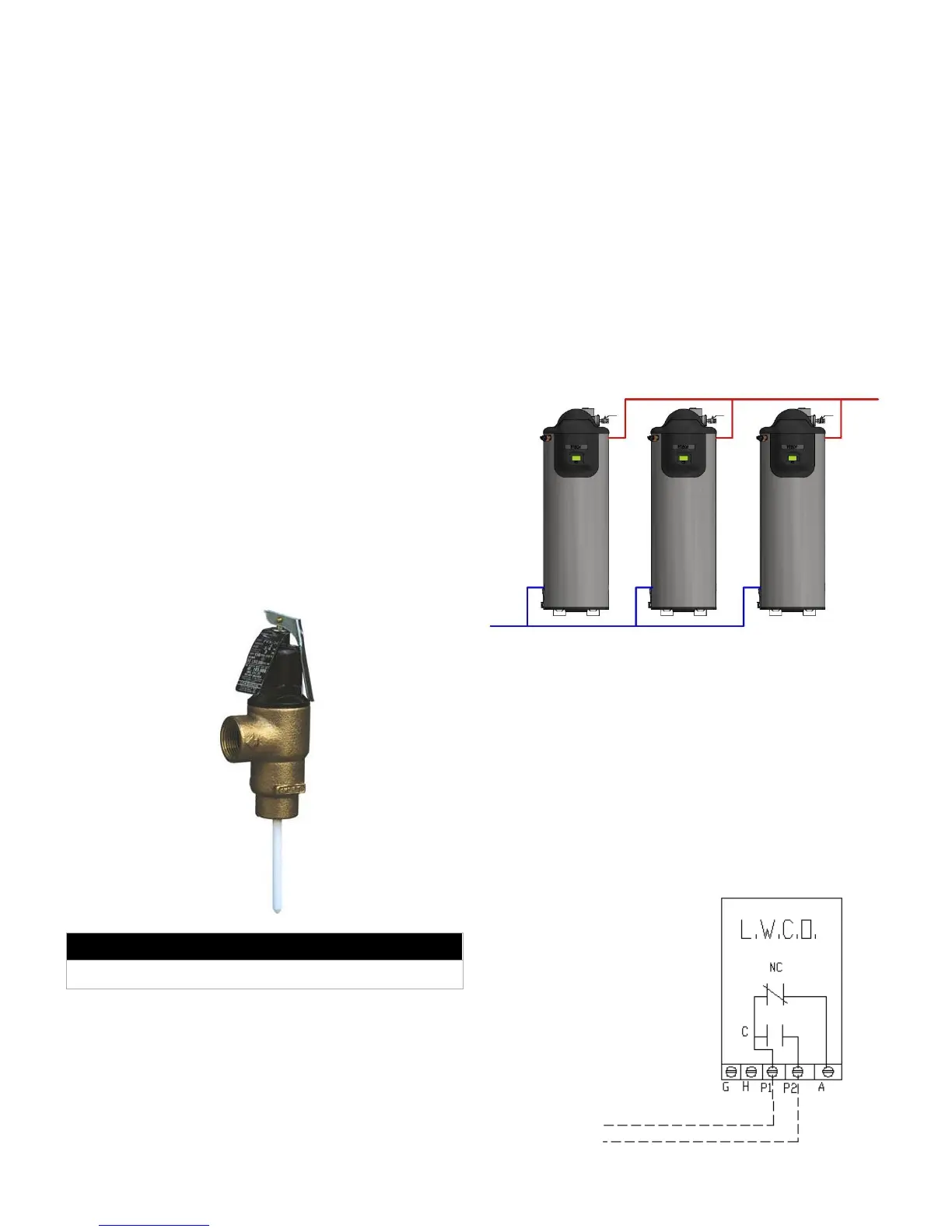

If multiple units are installed together, piping to the units must be

arranged such that each unit has the same length of pipe

connected to it, in order to balance the flow. The recommended

configuration would be “Reverse-Return”, where the unit closest

to the incoming supply connection is the furthest from the system

supply connection.

VTech Reverse-Return Piping Configuration

5.3 – Hydraulic Safeties

All safeties are installed in a common circuit, ensuring any safety

is capable of deactivating the unit. Please see the electrical

drawings in this manual for more information.

5.3.1 – Low Water Cut-off (LWCO)

If the VTech is installed above the hot water distribution system

(as is the case with penthouse mechanical room installations),

then a LWCO device may be required. Some local codes require

the installation of a LWCO on all systems. Low water cut-offs

should be tested every six months.

Watts LWCO - Electrical Connections

Loading...

Loading...