Section 01 TECHNICAL MANUAL

Subsection 02 (AIR CONTROLLED SUSPENSION (ACS))

vmr2010-004-108

Pressure Transducer Ground Test

1. Remove seats and RH side panel.

2. Disconnect pressure transducer connector.

vmr2010-004-104_a

1. Pressure transducer connector

3. Set the FLUKE 115 MULTIMETER (P/N 529 035

868)

to Vdc.

4. Place ignition switch to ON position.

5. Measure voltage as per the following table.

TEST PROBES VOLTAGE

Pin 1 (BK/GY)

Battery positive (+) post

Battery voltage

(± 12 Vdc)

Refer to the following illustration for the pressure

transducer connector pinout.

vmr2010-004-108

Pressure Transducer Replacement

1. Release air pressure, refer to

RELEASING AIR

PRESSURE IN SYSTEM FOR SERVICING

in this

subsection.

2. Disconnect pressure transducer connector.

3. Remove Oetiker clamp.

4. Remove pressure transducer from hose.

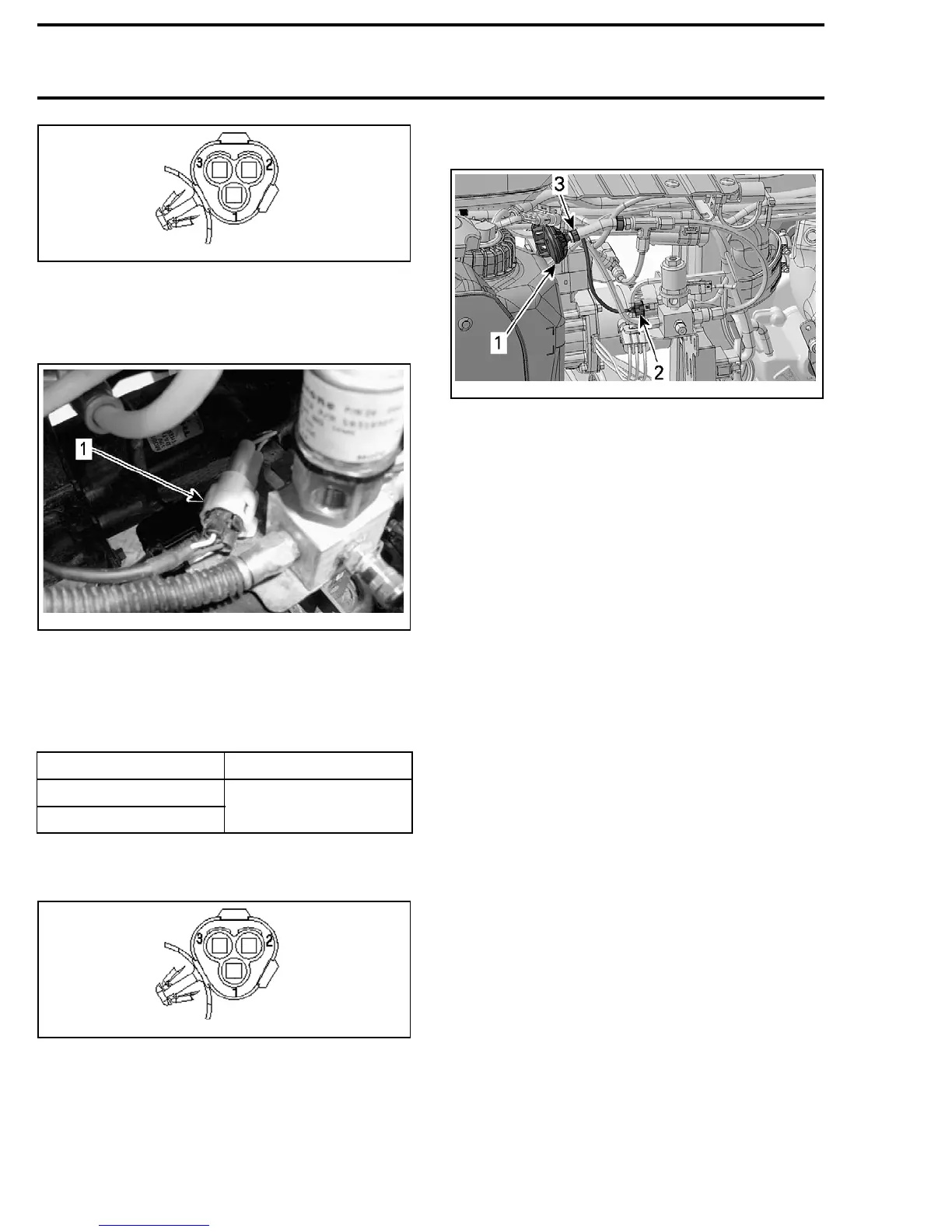

vmr2010-004-030_a

1. Auxiliary line pressure transducer

2. Connector

3. Oetiker clamp

5. Install a new pressure transducer on hose.

6. Install a new Oetiker clamp using

OETIKER PLI-

ERS (P/N 295 000 070)

.

7. Connect pressure transducer connector.

8. Ensure that there is no air leaks from pressure

transducer hose. Refer to

ACS SYSTEM LEAK

TEST (WITH B.U.D.S.)

.

ACS HOSES

ACS Hose and Fitting Replacement

1. Release air pressure, refer to

RELEASING AIR

PRESSURE IN SYSTEM FOR SERVICING

in this

subsection.

2. Locate hose or fitting to be replaced.

3. Remove it from vehicle.

4. Install the new hose or fitting.

5. Perform a

ACS SYSTEM LEAK TEST (WITH

B.U.D.S.)

.

Auxiliary Line Adapter Replacement

1. Release air pressure, refer to

RELEASING AIR

PRESSURE IN SYSTEM FOR SERVICING

in this

subsection.

2. Disconnect auxiliary line hose from adapter as

follows:

2.1 Push fitting ring toward adapter.

2.2 Hold ring in place.

2.3 Pull air hose.

44 vmr2010-004

Loading...

Loading...