6

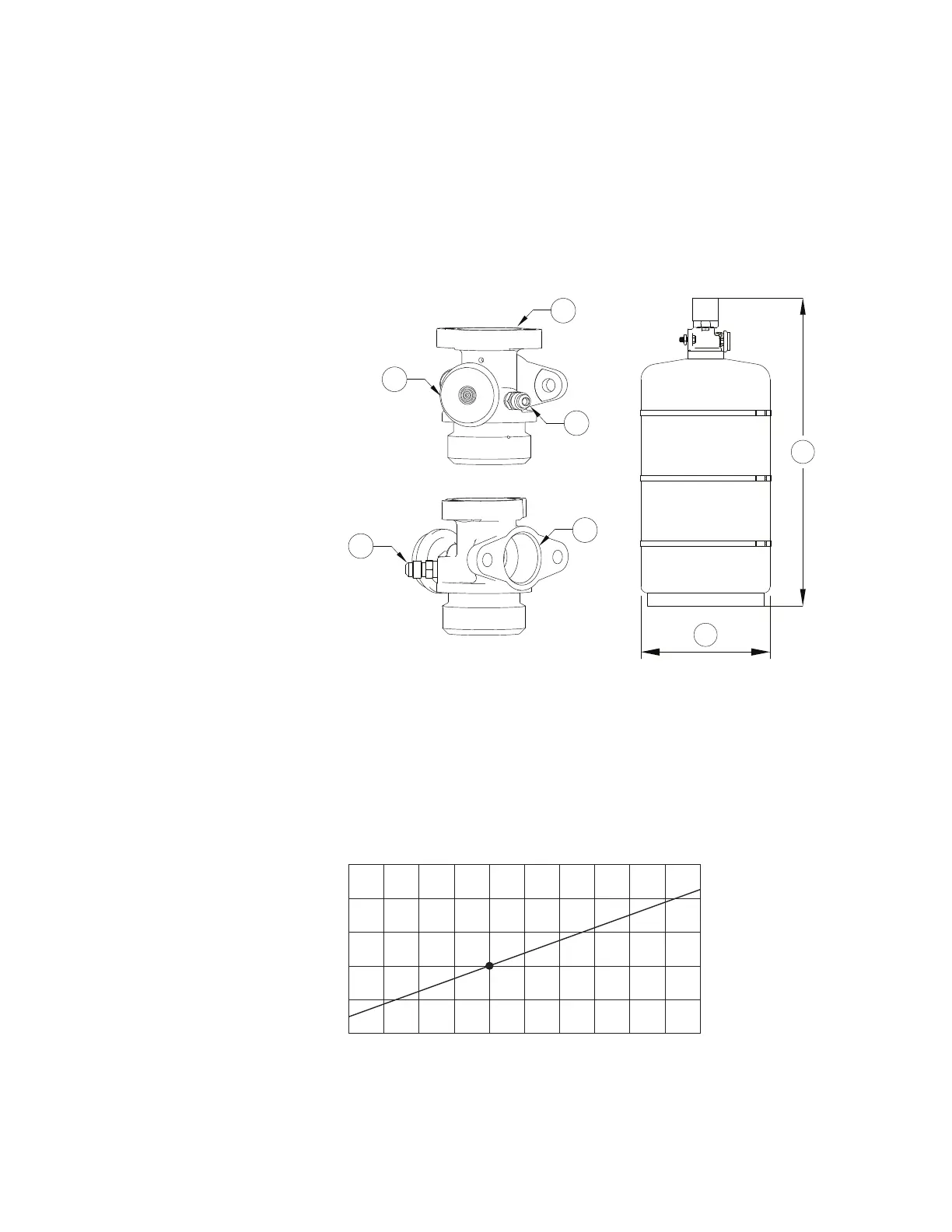

Cylinder Assembly

The EWC cylinder assembly (p/n 87-300001-001) uses a mild steel cylinder, conforming to 4BW250 DOT

& 4BWM-17 TC specifications, and a nickel-plated brass valve with pressure indicator gauge. Each valve

includes a Schrader port for connection to the primary actuator hose (for primary cylinders) or the optional

supervisory pressure switch (for secondary cylinders).

Each cylinder assembly is factory-filled with CAS liquid fire suppressant and pressurized to 200 PSIG

(1379 kPA) at 70°F (21°C). Each cylinder supports up to 6 flow points.

Figure 3 - Cylinder Tank Details

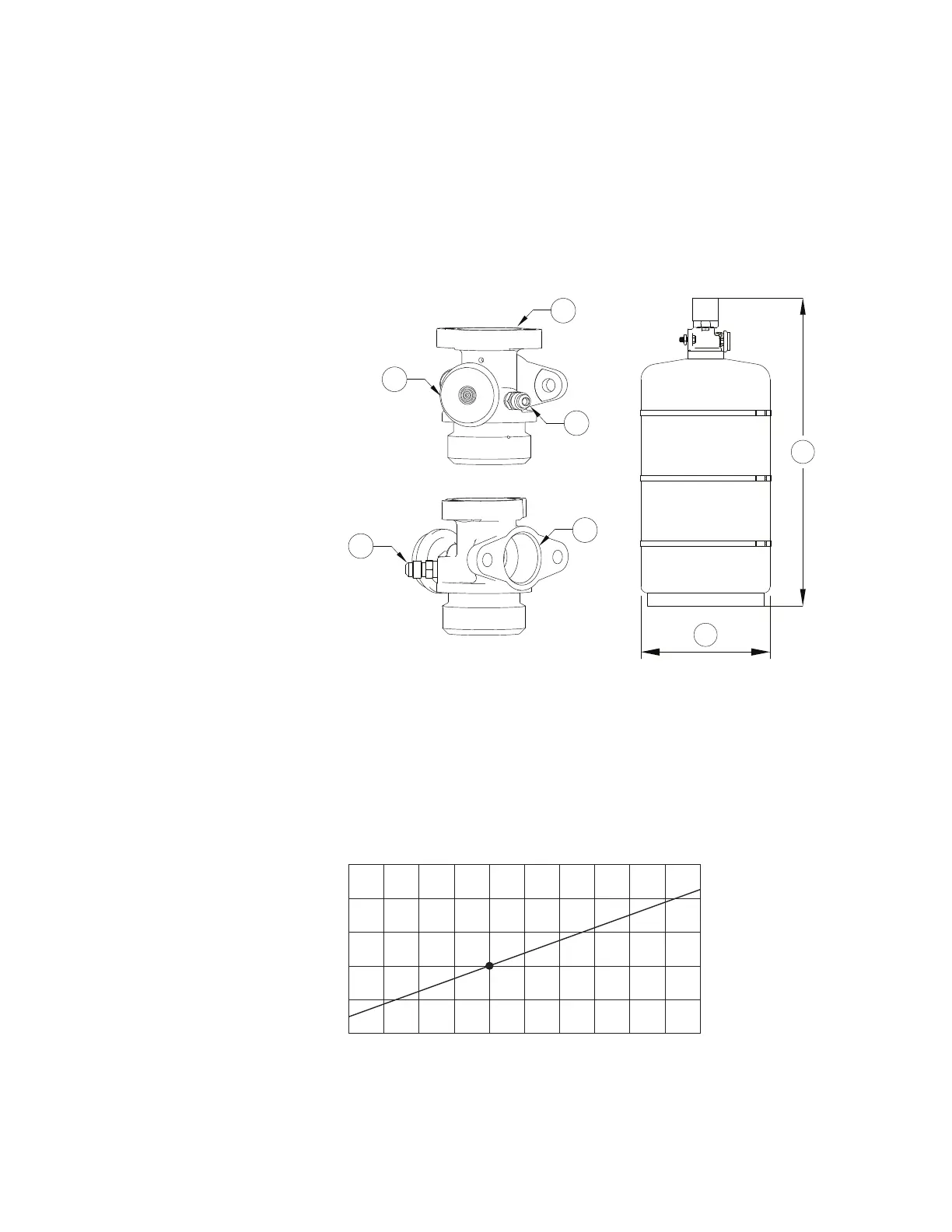

The pressure of a cylinder will vary with the ambient temperature, as detailed in Table 1. The gauge

indicator (shown in Figure 3) should be in the acceptable ‘green’ range for a cylinder that is properly

pressurized and within the listed operating temperature range. For a cylinder at the lowest listed operating

temperature of 32°F (0°C), the pressure gauge should read approximately 185 psig (the lower end of the

green range). For a cylinder at the highest listed operating temperature of 132°F (54.4°C), the pressure

gauge should read approximately 224 psig (the upper end of the green range).

Table 1 - Cylinder Temperature Vs Pressure

1. Valve Actuation Interface

2. Schrader Valve

3. Pressure Gauge

4. Discharge Outlet

A. Tank to Actuator Distance =

23-1/4”

B. Tank Diameter = 10”

230

(1586 kPA)

220

(1517 kPA)

210

(1448 kPA)

200

(1378 kPA)

190

(1309 kPA)

180

(1240 kPA)

30

(-1)

40

(4)

50

(10)

60

(15.6)

70

(21)

80

(27)

90

(32)

100

(38)

110

(43.3)

120

(49)

130

(54.4)

Temperature °F (°C)

Pressure PSIG (kPa)

Loading...

Loading...