15

ENGLISH

EVD

4

+030220227 - rel. 2.1 - 12.06.2008

Key:

= Main parameters required to start operation;

= Secondary parameters required for optimum operation;

— = Advanced parameters.

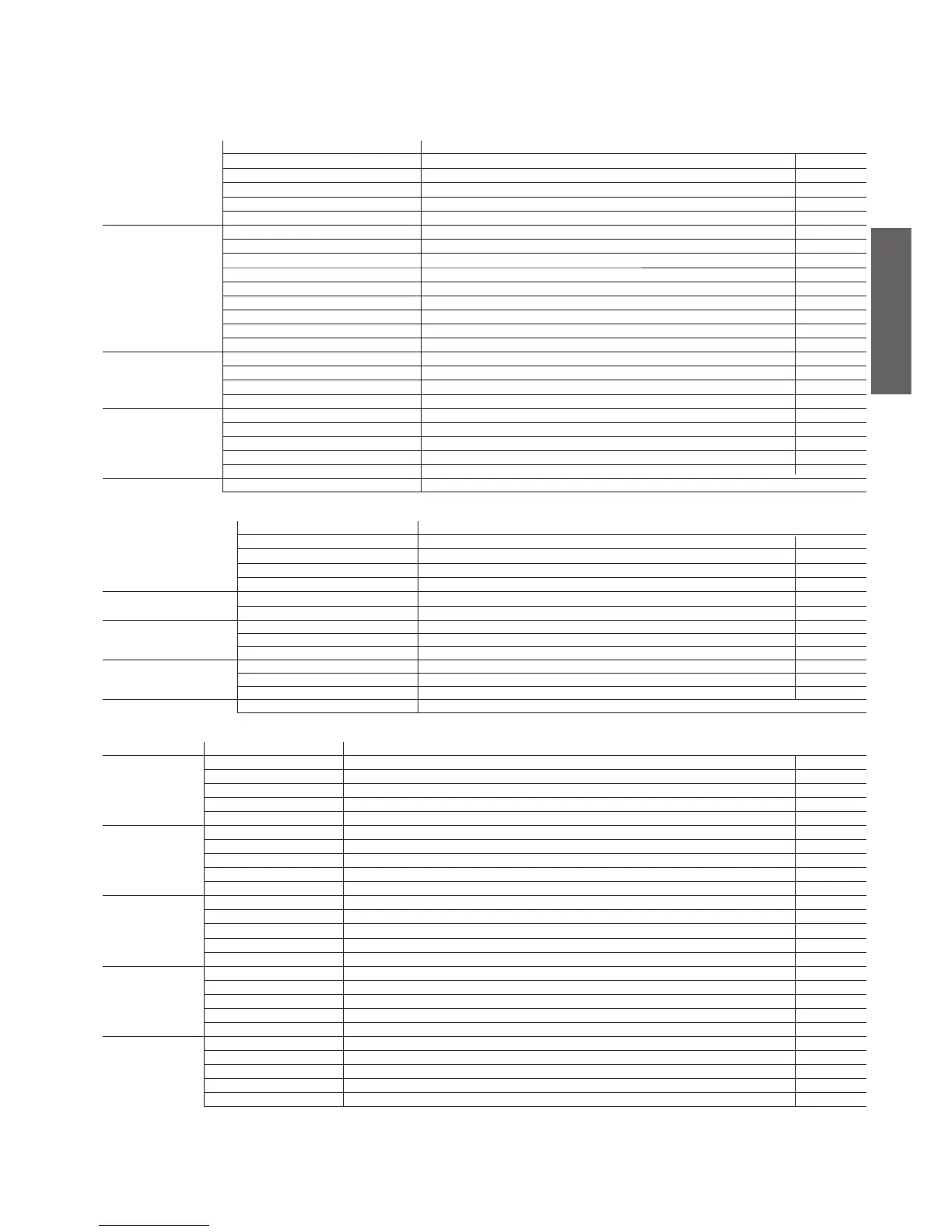

MANUFACTURER group

SYSTEM SET

Parameter name Description

EVD type

model of EVD used, from pCO

EVD probes type

number indicating the combination of sensors used to calculate the superheat

Valve type

number that defi nes the type of electronic valve used

Battery presence

enable valve not closed error, to be entered if the battery is present

Refrigerant

number indicating the type of refrigerant used

Custom valve confi guration

Minimum steps

minimum control steps

—

Maximum steps

maximum control steps

—

Closing steps

steps completed in total closing —

Opening extra steps

enable extra steps in opening —

Closing extra steps

enable extra steps in closing —

Phase current

peak current per phase —

Still current

current with the motor off —

Steprate

motor speed —

Duty cycle

motor duty cycle

—

EEV stand-by steps

number of valve standby steps, see standby steps —

S1 probe limits Min

‘zero’ scale for pressure sensor on input S1

S1 probe limits Max

end scale for pressure sensor on input S1

S2-Pt1000 calib.

calibration index for PT1000 sensor —

Alarms delay

Alarms delay Low SH

low superheat alarm delay

—

Alarms delay High SH

high superheat temperature alarm delay in CH mode —

Alarms delay LOP

low evaporation pressure (LOP) alarm delay —

Alarms delay MOP

high evaporation pressure (MOP) alarm delay —

Alarms delay probe error

probe error alarm delay —

Stand alone enable StandAlone

AUTOSETUP

Parameter name Description

Re-install AUTOSETUP values

confi rm enable restore parameter default values

Circuit/EEV ratio

percentage of the maximum capacity managed by the valve in the circuit where it is installed

Compressor or unit

macroblock parameter that defi nes the integral time

Capacity control

macroblock parameter that defi nes the proportional factor

Evaporator Type Cool

macroblock parameter that defi nes the integral time

Heat

macroblock parameter that defi nes the integral time

Cool Mode

temperature at minimum operating pressure (MOP) in CH mode

Heat Mode

temperature at minimum operating pressure (LOP) in HP mode

Defr. Mode

temperature at minimum operating pressure (LOP) in DF mode

MOP

Cool Mode

temperature at maximum operating pressure (MOP) in CH mode

Standby steps

temperature at maximum operating pressure (MOP) in HP mode

Defr. Mode

temperature at maximum operating pressure (MOP) in DF mode

High SH alarm threshold maximum superheat temperature

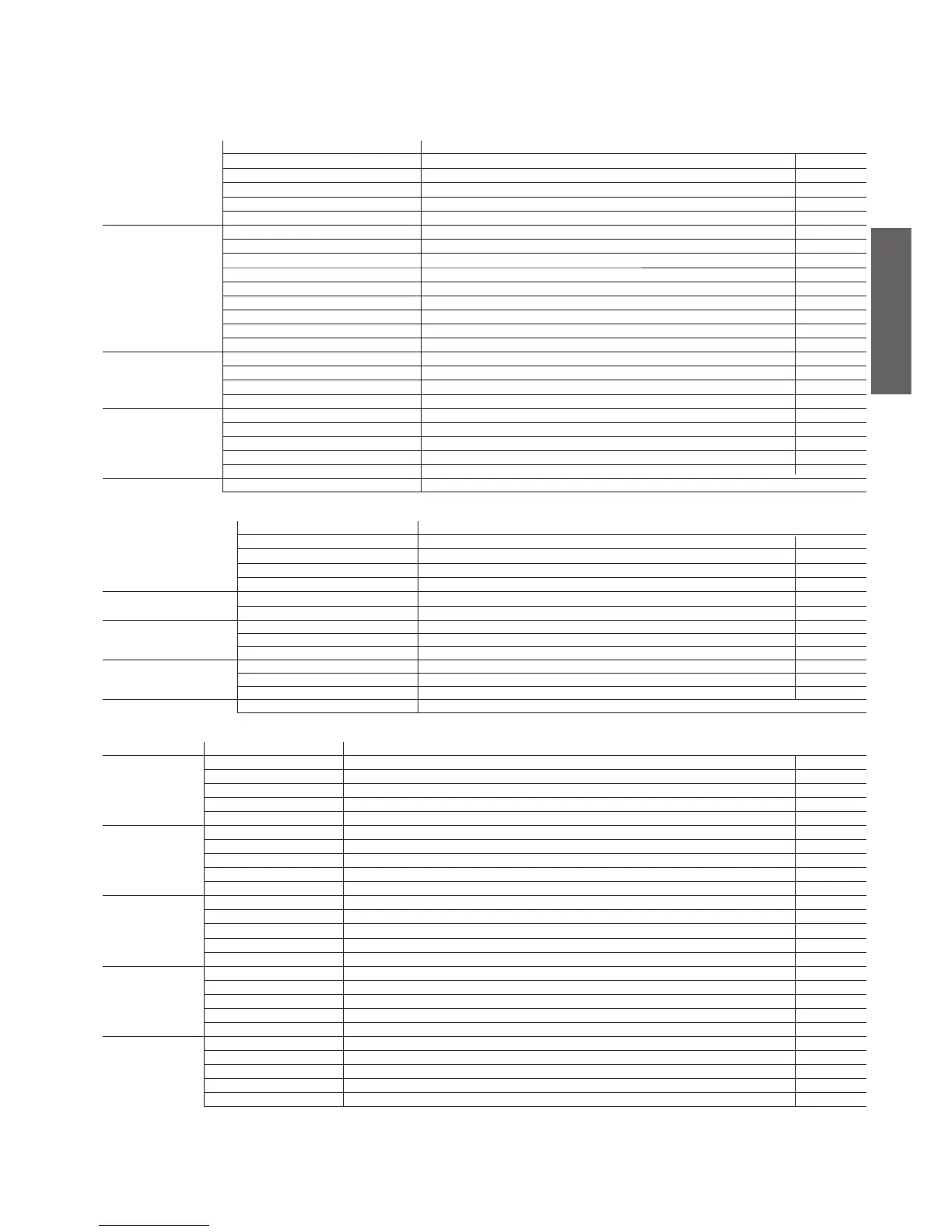

ADVANCED SETTINGS – FINE TUNING

Parameter name Description

CH-Circuit/EEV Ratio

percentage of the maximum capacity managed by the valve in the circuit where it is installed, in CH mode —

CH-Superheat set

superheat set point in CH mode

—

cool mode adjust CH-Proportional gain

PID proportional factor in CH mode

—

CH-Integral time

integral time for superheat control in CH mode

—

CH-Low Superheat

low superheat value in CH mode —

heat mode adjust

HP-Circuit/EEV Ratio

percentage of the maximum capacity managed by the valve in the circuit where it is installed, in HP mode —

HP-Superheat set

superheat set point in HP mode —

HP-Proportional gain

PID proportional factor in HP mode —

HP-Integral time

integral time for superheat control in HP mode —

HP-Low Superheat

low superheat value in HP mode

—

defr. mode adjust

DF-Circuit/EEV Ratio

percentage of the maximum capacity managed by the valve in the circuit where it is installed, in DF mode

—

DF-Superheat set

superheat set point in DF mode —

DF-Proportional gain

PID proportional factor in DF mode —

DF-Integral time

integral time for superheat control in DF mode —

DF-Low Superheat

low superheat value in DF mode —

common list adjust

SHeat dead zone

dead zone for PID control —

Derivative time

PID derivative time —

Low SHeat int. time

integral time for low superheat control —

LOP integral time

integral time for low evaporation pressure (LOP) control —

MOP integral time

integral time for high evaporation pressure (MOP) control —

MOP startup delay

MOP delay time —

Hi TCond. protection

maximum condensing temperature —

Hi TCond. int. time

integral time for high condensing pressure control (HiTcond) —

Dynamic prop. gain

attenuation coeffi cient with change in capacity —

Blocked valve check

time after which, in certain conditions, the valve is considered as being blocked —

Loading...

Loading...