23

ENG

ir33plus +0300028EN rel. 1.1 - 05.05.2017

ir33+, ir33+ wide, easy wide

par. H2

FUNCTION 0123456

LIGHT Y Y Y Y Y Y Y

AUX YYYYYYY

ON/OFF Y Y Y Y N N Y

HACCP YYYYYYY

PRG/MUTE (mute) Y Y Y Y Y Y Y

UP+DOWN (continuous cycle) Y Y Y Y N N N

SET/DEF (defrost) Y Y Y Y N N N

SET (set point) setting N Y N Y Y N N

“F” parameter setting N Y N Y N N N

Tab. 4.h

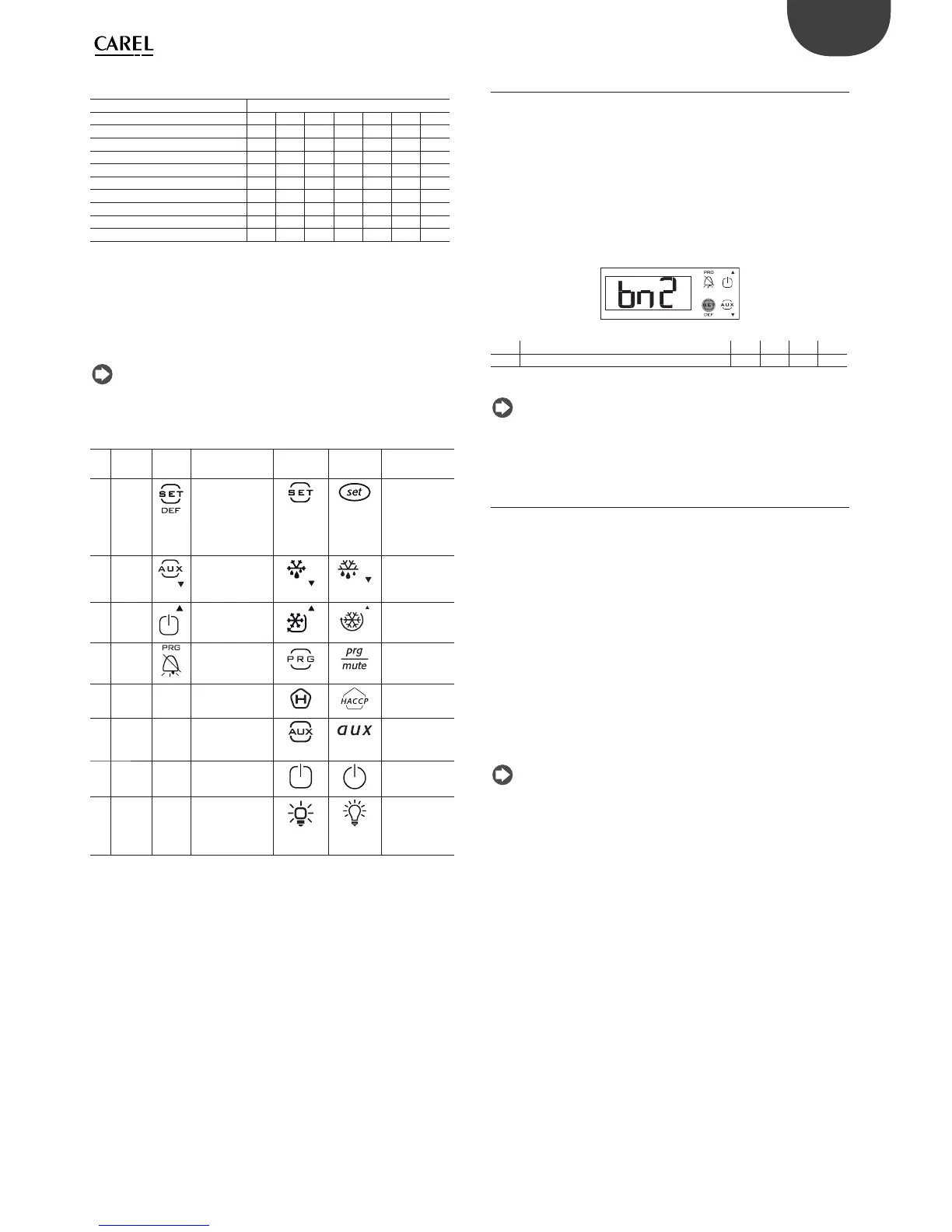

Disable buttons

Using the individual bits, the functions relating to the buttons on the

keypad can be enabled or disabled, according to the relationships shown

in the table below: to calculate the value to be assigned to parameter H6,

simply sum the values assigned to the functions that should be disabled.

Note: the functions disabled using parameter H6 are added to

those disabled using parameter H2.

Disable buttons

Bit Value

par. H6

ir33+

button

ir33+ function ir33+wide

button

easy wide

button

Description

01

Display defrost

temp. proce-

dure; access

HACCP; defrost

Display defrost

temp. proce-

dure

12

Activate AUX

output 1, conti-

nuous cycle

Defrost

24

Up, On-O Continuous

cycle

38

Mute alarms Mute alarms

416 - -

Access HACCP

532 - -

Activate/

deactivate aux

output 1

664 - -

On/O

7 128 - -

Activate/

deactivate aux

output 2, light

Tab. 4.i

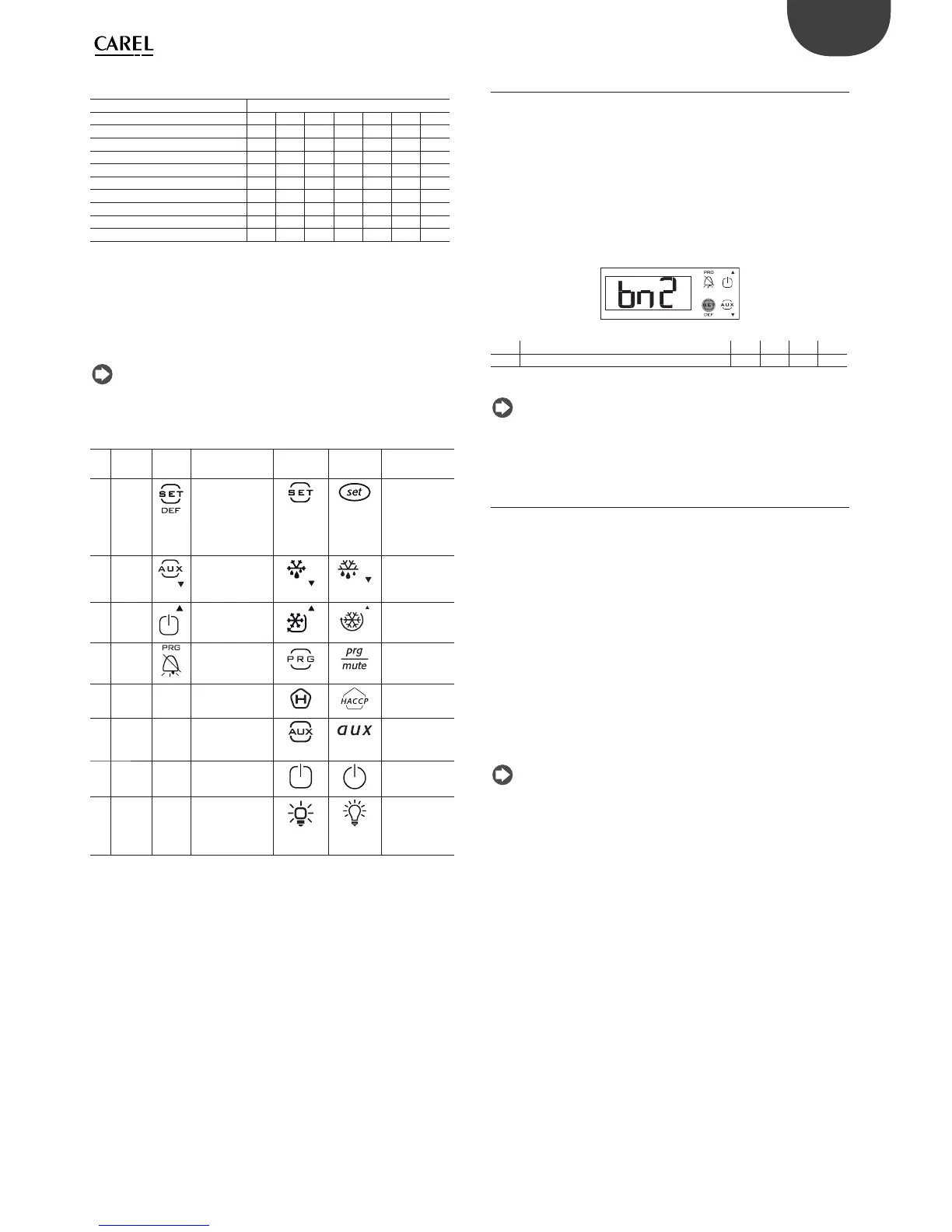

4.2 Loading the sets of parameters

Up to 6 sets of custom parameters can be selected on the controller, after

having been loaded using the VPM programming tool (Visual Parameter

Manager, see appendix 1) and the programming key.

Procedure:

• power down the controller;

• power up while holding Prg/mute;

• the display will show the rst set: bn0;

• press UP/DOWN to select set bn1 to bn6. For example, select bn2;

• press Set to con rm the selected set: the controller will load the set

of parameters called bn2 and then will return to the standard display.

Par. Description Def Min Max UOM

Hdn Number of default parameter sets available 0 0 6 -

Tab. 4.j

Note: bn0 is the default set of parameters on the controller, i.e. the

default con guration. When one of sets bn1 to bn6 is loaded, bn0 is

overwritten with the new set and is consequently erased.

4.3 Preparing for operation

Once having completed the installation, con guration and programming

procedures, before starting the controller, check that:

• the wiring has been completed correctly;

• the programming logic is suitable for controlling the unit and the

system being managed;

• if the controller is tted with RTC (clock), set the current time and date,

and the on and o times for the light/auxiliary output;

• set the standard display;

• set the “probe type” parameter based on the probe available and the

type of control (NTC, NTC-HT, PTC); note that the controllers that use

PTC probes may have di erent part numbers from those that only use

NTC probes;

• set the type of defrost: heater or hot gas;

• set the temperature unit of measure (°C or °F);

• the protection functions (delay at start-up, rotation, minimum on and

o times for the outputs) are active.

Note: all the alarms with manual reset can be reset by pressing the

Prg and UP buttons together for more than 5 seconds. See the chapter on

“Alarms”.

Loading...

Loading...