E N G L I S H

µC

2

- +030220731 - rel. 1.2 - 26.10.2007

• Control settings: parameters (r*)

- Cooling set point

r01: between r13 and r14

r02: cooling differential

- Heating set point (heat pump)

r03: between r15 and r16

r04: heating differential

- Compressor rotation

r05: The rotation of the compressors allows the operating hours to be balanced either statistically, using

FIFO logic, or absolutely, by counting the effective operating hours.

Settings:

r05=0: rotation disabled; The customer can use compressors with different power ratings according

to the desired logic or manage the capacity-control functions. The compressors are started/stopped in

proportional mode.

r05=1: rotation with FIFO logic (first ON, first OFF, and vice-versa first OFF, first ON); in this mode the

operating hours are optimised together with the number of starts, even if the compressor safety times are

always respected.

r05=2: rotation with control of operating hours; in this way the compressors will have the same operating

hours, as the compressor with the least operating hours is always started first, again observing the safety

times. This does not however consider FIFO logic and does not optimise the starts and stops.

In the case of capacity controlled compressors (1 per circuit), FIFO logic or timed operation will refer to

the actual circuit and not the compressor valves. If, for example, when capacity is required from circuit 1,

compressor 1 starts first, capacity controlled (not at full capacity), and then the valve is managed as a se-

cond step, so that the compressor will work at maximum efficiency. If less capacity is required, the second

step will be deactivated first, and then the compressor. There is no rotation between the compressor and

the valve. If extra capacity is required, the second circuit will start with compressor 2 and then, if required,

the valve is operated.

When stopping, the valve is managed first and then the actual compressor as a whole. Both FIFO logic

and timed operation will involve either one circuit or the other. The activation and deactivation of the val-

ves are not subject to timers, but rather only a hysteresis that is equal to the set point and the differential

of the step (in fact the valve performs the same function as a hermetic compressor).

r05=3: direct correspondence between the digital inputs and the compressor relays (condensing units

only).

- Type of compressor control

r06: This parameter is used to set the logic for maintaining the set point:

r06= 0: proportional on inlet

r06= 1: proportional on inlet + dead zone (see Dead zone, below)

r06= 2: proportional on outlet

r06= 3: proportional on outlet with dead zone

r06= 4: on outlet by time with dead zone (see timed outlet temperature control)

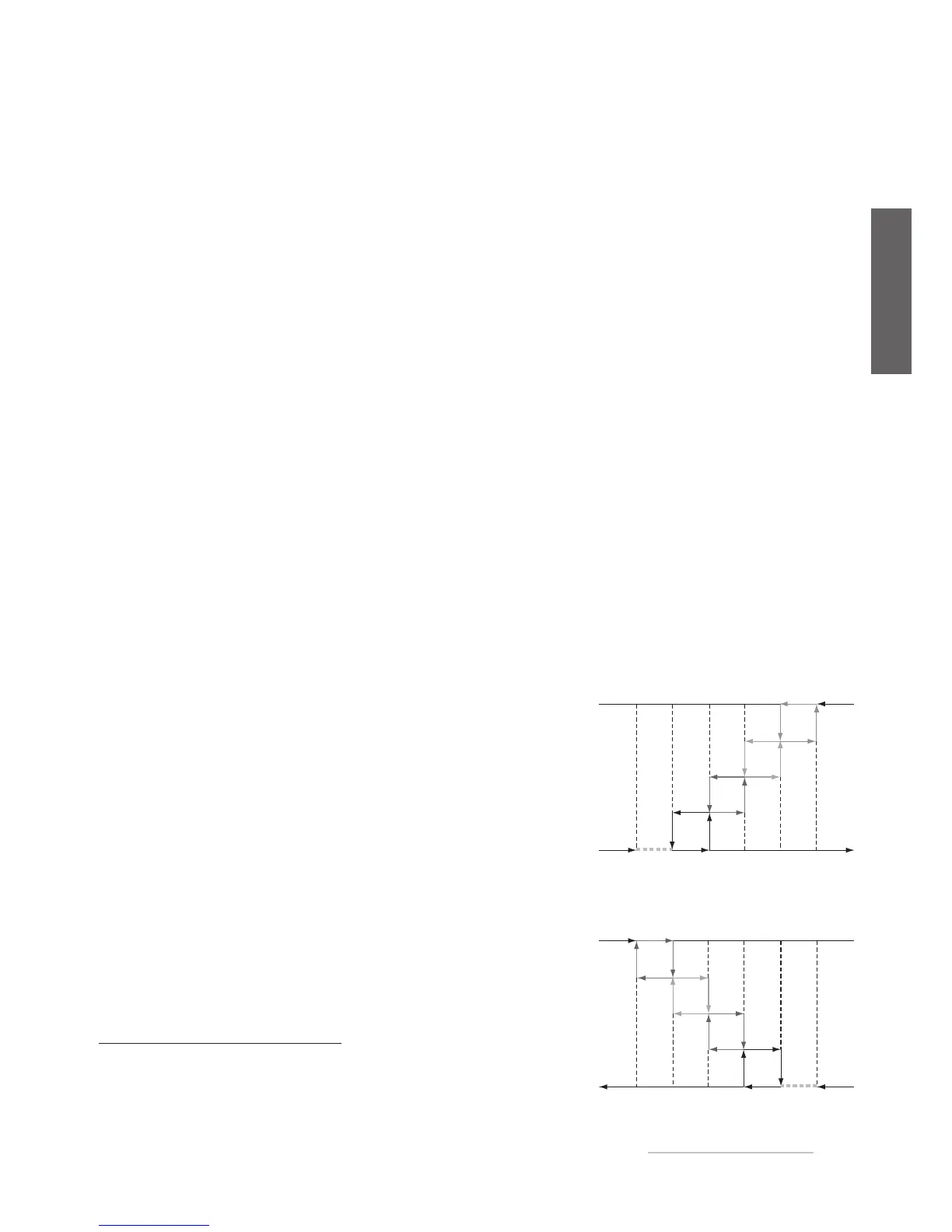

DEAD ZONE

The dead zone essentially shifts the proportional band from the set

point by the value set for the parameter r07.This parameter is valid in

all configurations if enabled (for r07≠0: dead zone set and enabled).

Key Figure 5.b.c:

r06: enable the dead zone (enabled if r06=1 or 3)

r07: dead zone

r01: cooling set point

r02: cooling differential

In chiller (cooling) mode, the dead zone moves the cooling proportional band above the set point by the

value r07.

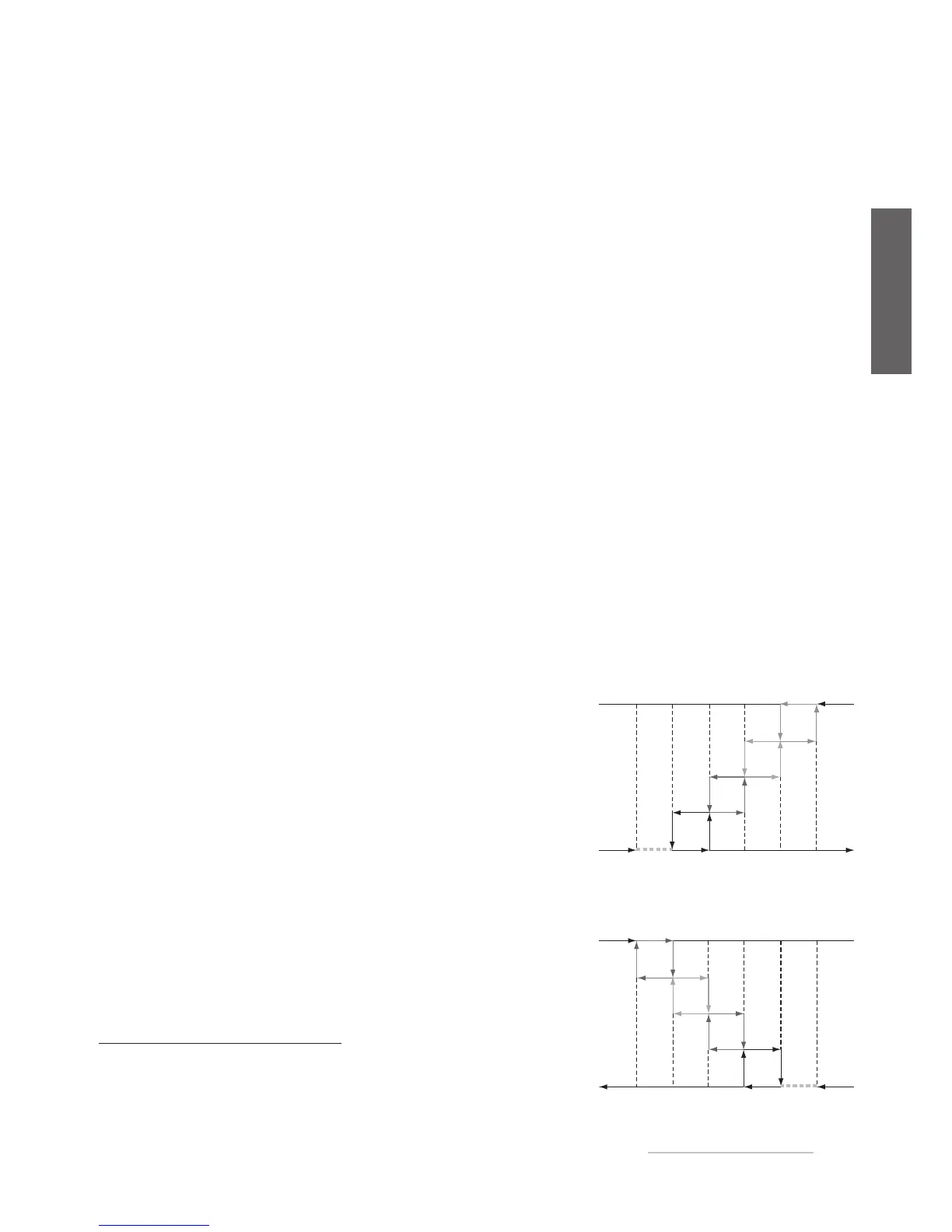

Key Figure 5.b.d:

r06: enable the dead zone (enabled if r06=1 or 3)

r07: dead zone

r03: heating set point

r04: heating differential

In heat pump (heating) mode, the dead zone moves the heating proportional band below the set point

by the value r07.

Outlet temperature control by time r06 = 4 (only chiller)

This type of control is based on the need to maintain the outlet temperature as constant as possible,

despite the load being variable or the reduced inertia of the system.

The logic has the aim of keeping the temperature inside the dead zone.

If outside the zone, the compressors will be activated with the logic described below, so as to return

inside the dead zone, neither too quickly (using an integral or derivative), nor too slowly, with fixed time

logic. There are two logical times involved: the activation time and deactivation time.

Fig. 5.b.c

Fig. 5.b.d

Loading...

Loading...