46

SET-UP, CONFIGURATION, AND

OPERATION

The Unit Ventilator Comfort Control module (P/N 110500)

is designed to be installed using the CCN Network Service

Tool, or a CCN Building Management system such as Building

Supervisor, ComfortVIEW™ or ComfortWORKS® software.

The control provides several comprehensive screens for easy

set-up and configuration of the control. See Tables 23-29. Two

additional screens display the operation of the equipment.

Each unit is factory-configured for the control sequence or-

dered. Only set points, schedules, alarm limits, and user op-

tions need to be adjusted. Tables 23-29 depict the screens that

provide a list of the information contained within each func-

tion, the expected range of values for each parameter, and the

allowable force limits or configuration range. For specific in-

formation about Network Service Tool, Building Supervisor,

ComfortVIEW, or ComfortWORKS software refer to the oper-

ating instructions for each specific piece of software.

The Service Configuration screens are used to specify the

equipment model and control sequence being used, such as the

type of heating or cooling used (chilled water, DX cooling,

steam, or hot water) and the damper control type (ASHRAE

Cycle I, II or III). These values are factory-configured for the

control sequence as ordered. A separate configuration screen is

used to modify the factory pre-configured alarm set points, if

required, in order to meet a specific customer requirement.

The service configuration screens are located under the

Diagnostic/Service Configuration function. See Table 24.

Alarm configurations are shown in Table 25.

The Modify controller screen allows the installer to select

from a list of standard control options which can be used for

specific applications. Standard control options include Space

Temperature Set Point adjustment with an adjustable maxi-

mum limit, the ability to provide dehumidification with or

without reheat, override duration, unoccupied free cooling, or

warm up temperature check, and other control features.

The control configuration screens are located under the

CCN Configuration function. See Table 27.

The Set Point screen is used to configure the desired control

set points for the specific application. These set points include

the occupied heating and cooling set points, the unoccupied

heating and cooling set points, the ventilation airflow set point,

the IAQ set point (optional) and the ASHRAE Cycle III Damp-

er set point (for Cycle III control). The Set Point screen is locat-

ed under the Modify/Set Points function. See Table 28.

The Points/Display screen is used to monitor equipment

operation and provides a simple overview including: the oper-

ating mode, heating and cooling capacity, ventilation airflow

value, equipment and sensor alarms, and a list of actual sensor

and output values. The Status Display screen is located under

the Points/Display function. See Table 26.

The Maintenance screen provides an indication of the

control algorithm operation and a view of each individual con-

trol loop as it is currently functioning. The Maintenance

screens are located under the Diagnostic/Maintenance func-

tion. See Table 29. The Linkage Maintenance screens are locat-

ed under the Diagnostic/Maintenance function. See Table 29.

The Maintenance screen provides an indication of the informa-

tion the Unit Ventilator Comfort Control module has received

from the linkage thermostat (if supplied).

LEGEND (For Tables 23-29)

Act — Actual

AQ — Air Quality

ASCII — American Standard Code

for Information

Interchange

ASHRAE — American Society of

Heating, Refrigeration

and Air Conditioning

Engineers

CCN — Carrier Comfort Network®

Cfg — Configured

Cntrl — Control

CV — Constant Volume

DI — Discrete Input

DX — Direct Expansion

Ele — Element

Hi Lim — High Limit

Hys — Hystersis

Kd — Derivative Constant

Ki — Integral Constant

Kp — Proportional Constant

Lo Lim — Low Limit

MAD — Mixed-Air Damper

MAT — Mixed Air Temperature

Sensor

Med — Medium

min — minute

Norm — Normal

Nr — Number

OAT — Outdoor-Air Temperature

Sensor

Oc/Occ — Occupied

PID — Proportional/Integral/

Derivative

Pos — Position

RH — Relative Humidity

Schd — Schedule

SP/Setpt — Setpoint

Stg — Stage

Sup Blk # — Supervisory Block

Number

Sup Bus — Supervisory Bus

Number

Sup Ele — Supervisory Element

Number

Temp/Tmp — Temperature

Tim Gard — Time Guard

Tmd Ovr — Timed Override

Tmd Ovr Hrs — Timed Override Hours

Unoc — Unoccupied

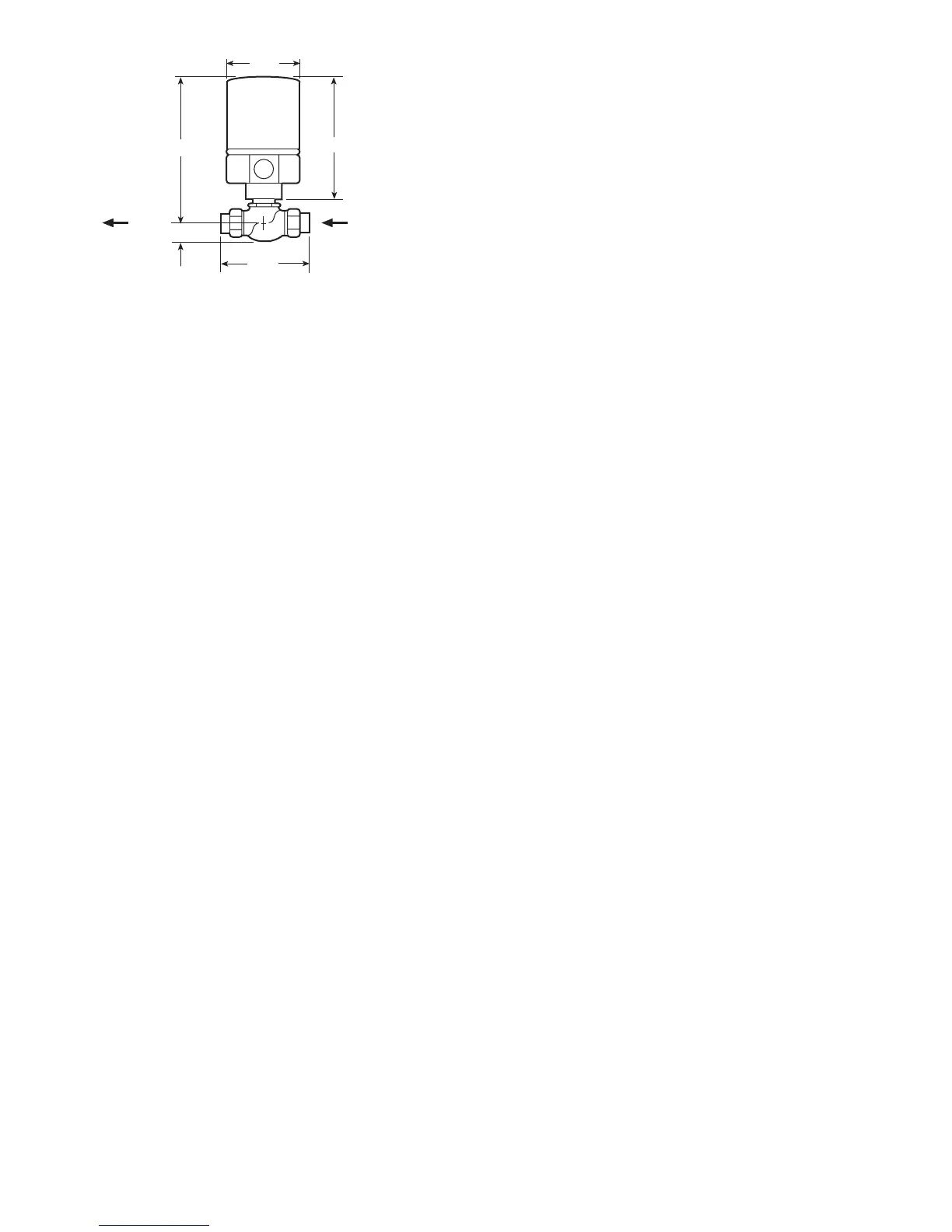

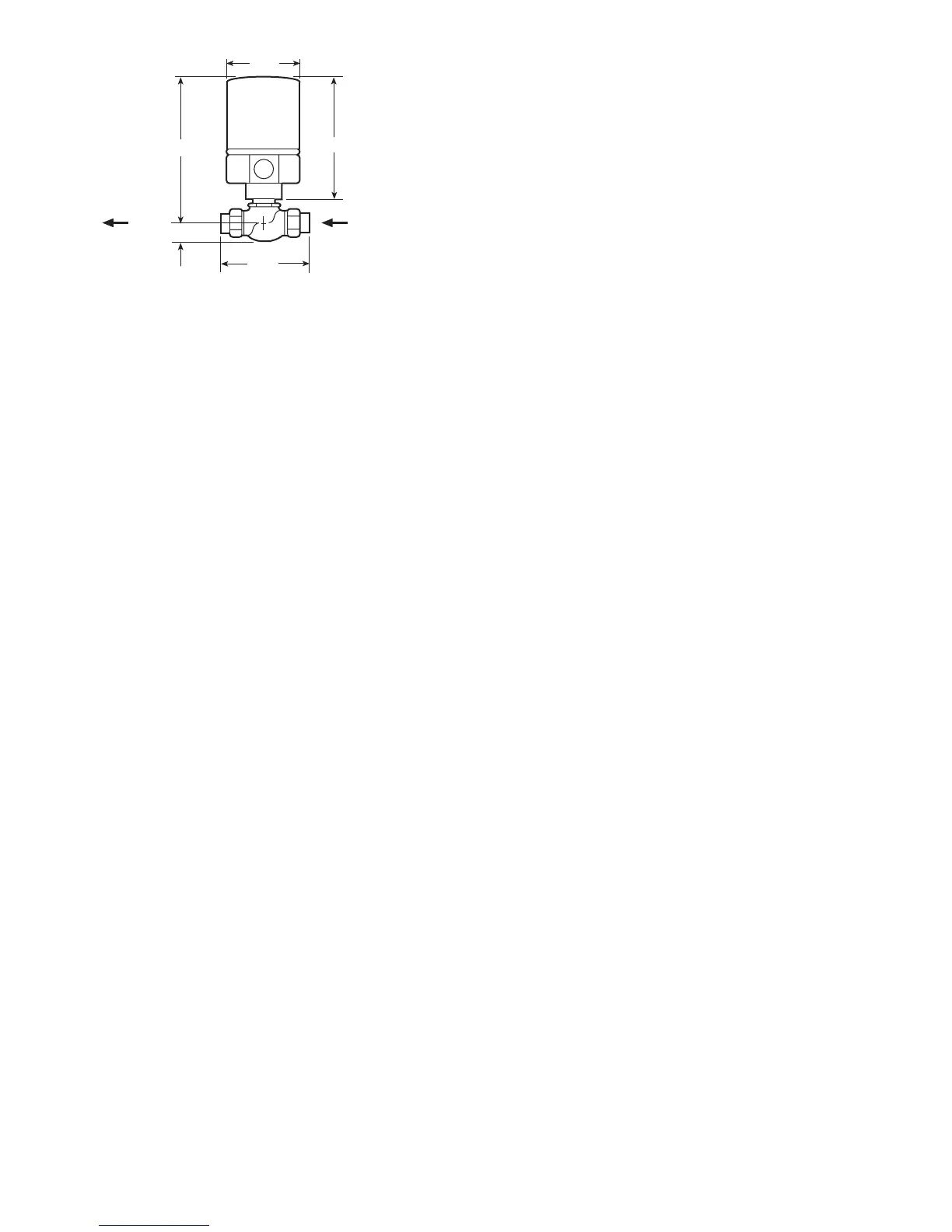

*9-25/32

6-3/4

4-1/4

3-1/4

1-5/16

FLOW

IN ‘A’

OUT

‘AB’

*Includes 2

1

/

32

-in. (52 mm) for linkage extension.

NOTES:

1. Allow 3 in. clearance above actuator for removal. Mount actua-

tors above the valve body at 45-degrees from vertical. Refer to

Fig. 32.

2. Dimensions are in inches.

Fig. 35 — Valve Dimensions

Loading...

Loading...