43

GAS VALVE

All three-phase models are equipped with 2-stage gas valves.

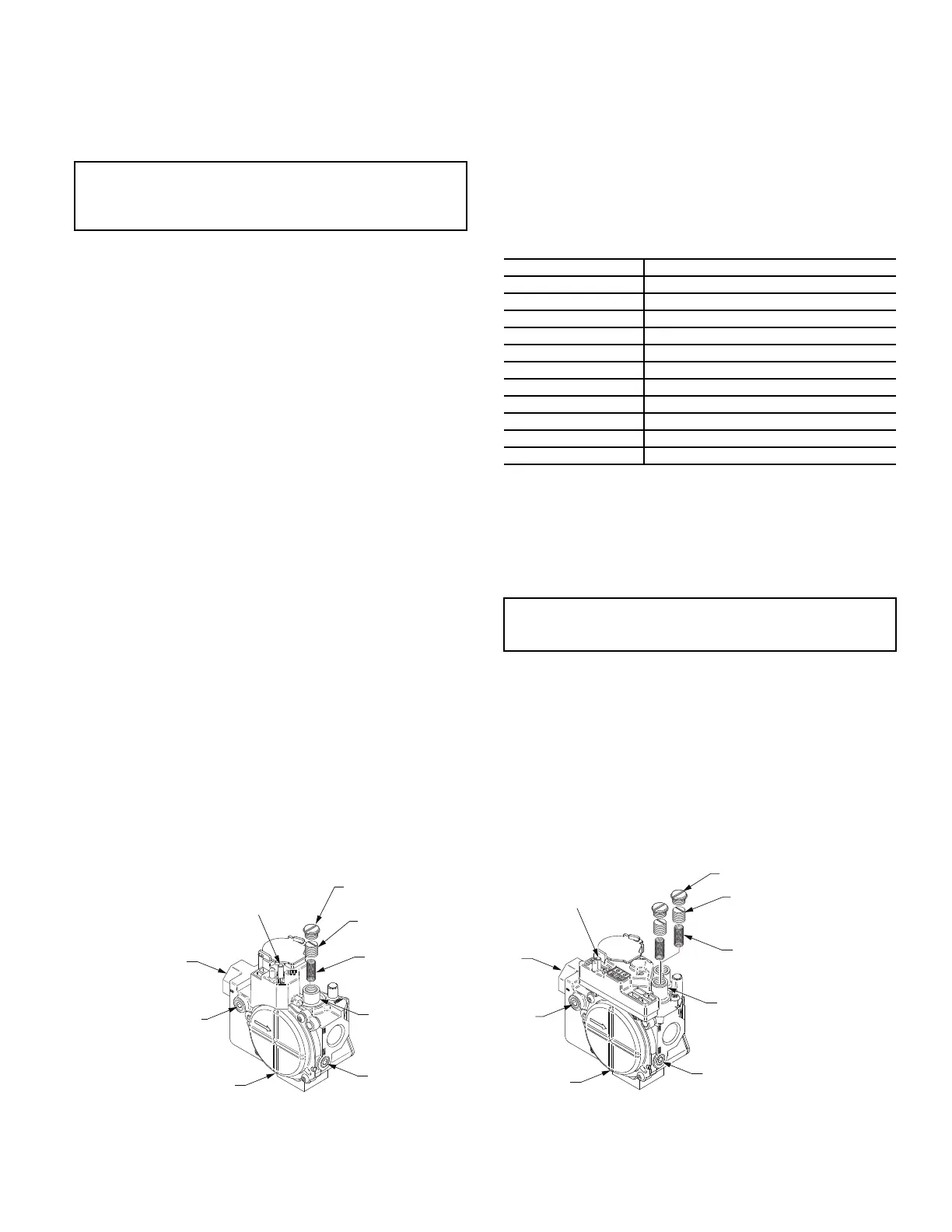

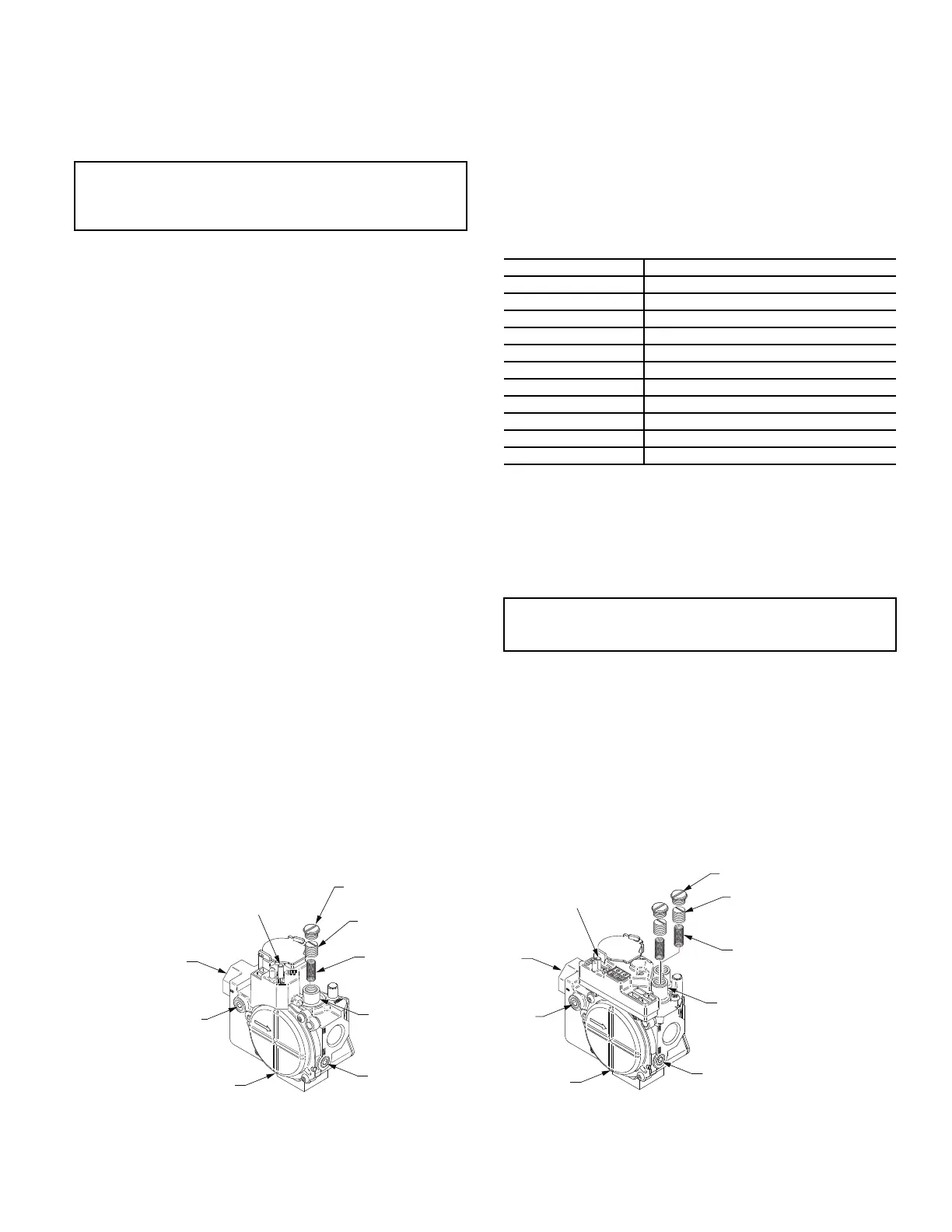

See Fig. 62 for locations of adjustment screws and features on

the gas valve.

To adjust gas valve pressure settings:

CHECK UNIT OPERATION AND MAKE NECESSARY

ADJUSTMENTS

NOTE: Gas supply pressure at gas valve inlet must be within

specified ranges for fuel type and unit size. For natural gas see

Tables 6 and 7. For liquid propane see Tables 8 and 9.

1. Slide out the burner partition panel.

2. Remove manifold pressure tap plug from manifold and

connect pressure gauge or manometer. (See Fig. 59.)

3. Turn on electrical supply.

4. Turn on unit main gas valve.

5. Set room thermostat to call for heat. If unit has two-stage

gas valve, verify high-stage heat operation before attempt-

ing to adjust manifold pressure.

6. When main burners ignite, check all fittings, manifold,

and orifices for leaks.

7. Adjust high-stage pressure to specified setting by turning

the plastic adjustment screw clockwise to increase pres-

sure, counter-clockwise to decrease pressure.

8. For two-stage gas valves, set room thermostat to call for low-

stage heat. Adjust low-stage pressure to specified setting.

9. Replace regulator cover screw(s) when finished.

10. Observe unit heating operation in both high stage and low

stage operation if so equipped. Observe burner flames to

see if they are blue in appearance, and that the flames are

approximately the same for each burner.

11. Turn off unit, remove pressure manometer and replace the

manifold pressure tap plug. (See Fig. 59.)

LIMIT SWITCH

Remove the indoor blower access panel. Limit switch is located

on the heat exchanger cover panel. See Fig. 58.

Burner Ignition

Unit is equipped with a direct spark ignition 100% lockout sys-

tem. The Integrated Gas Unit Controller (IGC) is located in the

control box (see Fig. 60). The IGC contains a self-diagnostic

LED (light-emitting diode). A single LED (see Fig. 63) on the

IGC provides a visual display of operational or sequential prob-

lems when the power supply is uninterrupted. When a break in

power occurs, the IGC will be reset (resulting in a loss of fault

history) and the indoor (evaporator) fan ON/OFF times will be

reset. The LED error code can be observed through the viewport.

During servicing, refer to the label on the control box cover or

Table 10 for an explanation of LED error code descriptions.

If lockout occurs, unit may be reset by interrupting power supply

to unit for at least 5 seconds.

Orifice Replacement

This unit uses orifice type LH32RFnnn (where “nnn” indicates

orifice reference size). When replacing unit orifices, order the

necessary parts through RCD. See the High Altitude Gas Con-

version Kit Gas Heating/Electric Cooling 3-15 Ton Small Roof-

top Units Accessory LP (Liquid Propane) Installation Instruc-

tions for details.

Ensure each replacement orifice is tight as its threads into the

manifold pipe and the orifice projection does not exceed maxi-

mum value. See Fig. 57.

Fig. 62 — Typical Gas Valves

IMPORTANT: Leak check all gas connections including the

main service connection, gas valve, gas spuds, and manifold

pipe plug. All leaks must be repaired before firing unit.

Table 10 — LED Error Code Descriptions

a

a. A 3-second pause exists between LED error code flashes. If more than one er-

ror code exists, all applicable codes will be displayed in numerical sequence.

LED INDICATION ERROR CODE DESCRIPTION

ON Normal Operation

OFF Hardware Failure

1 Flash

b

b. Indicates a code that is not an error. The unit will continue to operate when this

code is displayed.

Evaporator Fan On/Off Delay Modified

2 Flashes Limit Switch Fault

3 Flashes Flame Sense Fault

4 Flashes 4 Consecutive Limit Switch Faults

5 Flashes Ignition Lockout Fault

6 Flashes Induced-Draft Motor Fault

7 Flashes Rollout Switch Fault

8 Flashes Internal Control Fault

9 Flashes Software Lockout

LEGEND

LED — Light Emitting Diode

IMPORTANT: Refer to Tables 11 and 12 for additional

troubleshooting information.

Plastic Adjust

Screw

Regulator Spring

(Propane — White

Natural — Silver)

Gas Pressure

Regulator

Adjustment

Manifold

Pressure Tap

NPT Outlet

Inlet

Pressure

Tap

On/Off

Switch

Regulator

Cover Screw

NPT Inlet

Single Stage

Plastic Adjust

Screw (2)

Regulator Spring (2)

(Propane — White

Natural — Silver)

Low Stage

Gas Pressure

Regulator

Adjustment

Manifold

Pressure Tap

NPT Outlet

Inlet

Pressure

Tap

On/Off

Switch

Regulator

Cover Screw (2)

NPT Inlet

2 Stage

Loading...

Loading...