44

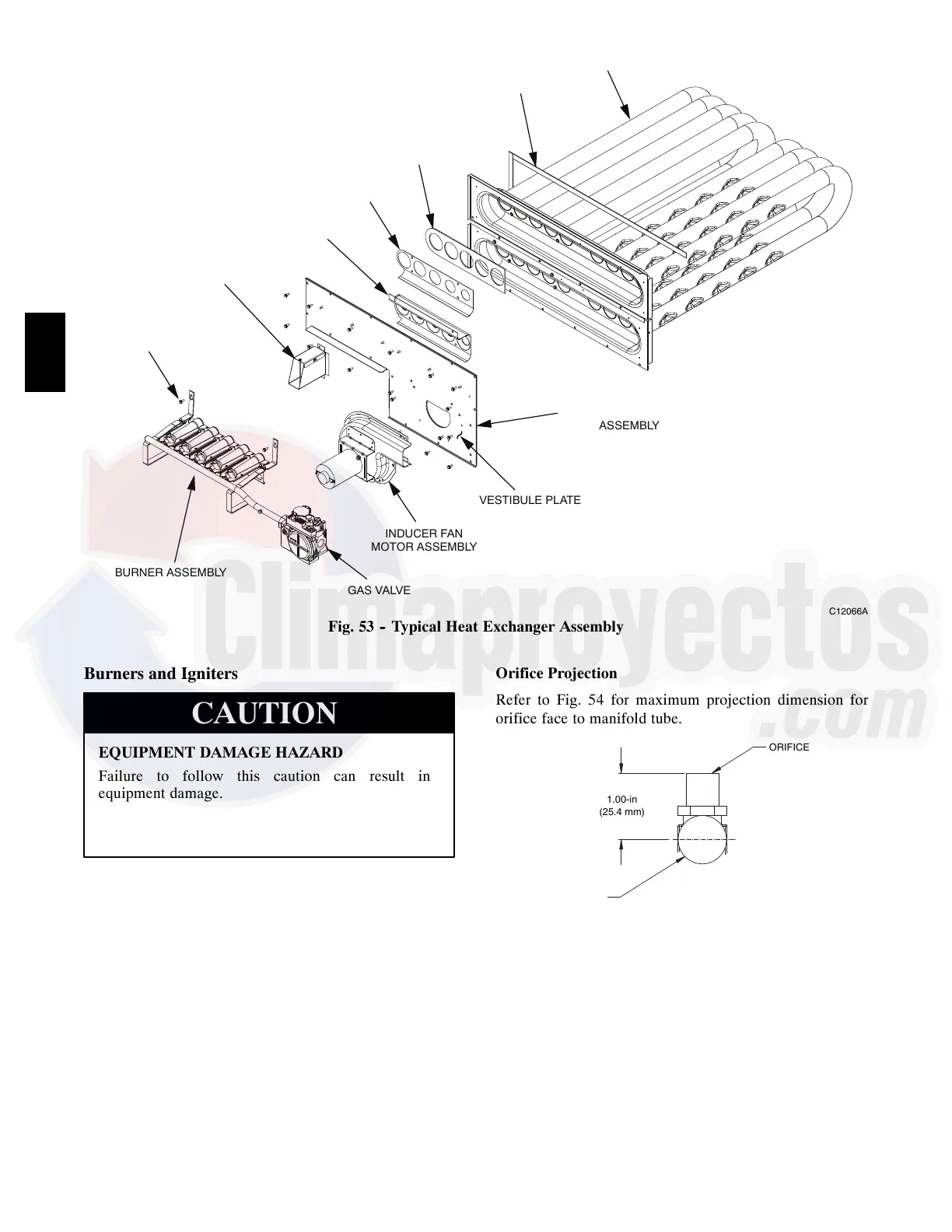

BURNER ASSEMBLY

GAS VALVE

INDUCER FAN

MOTOR ASSEMBLY

VESTIBULE PLATE

SUPPORT INSULATION

ASSEMBLY

HEATER TUBE

ASSEMBLY

SEAL STRIPS

(SPONGE RUBBER)

REGULATOR

GASKET

REGULATOR

RETAINER

WIND CAP ASSEMBLY

(SHOWN INVERTED

AS SHIPPED)

~

MOUNTING

SCREWS (2)

C12066A

Fig. 53 -- Typical Heat Exchanger Assembly

Burners and Igniters

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution can result in

equipment damage.

When working on gas train, do not hit or plug

orifice spuds.

CAUTION

Main Burners

To access the burner section, open the heater access door

below the indoor fan panel. At the beginning of each

heating season, inspect for deterioration or blockage due

to corrosion or other causes. Observe the main burner

flames and adjust, if necessary. Flames should be conical

in shape and enter the heat exchanger tubes with minor

impingement on sheet metal flame components.

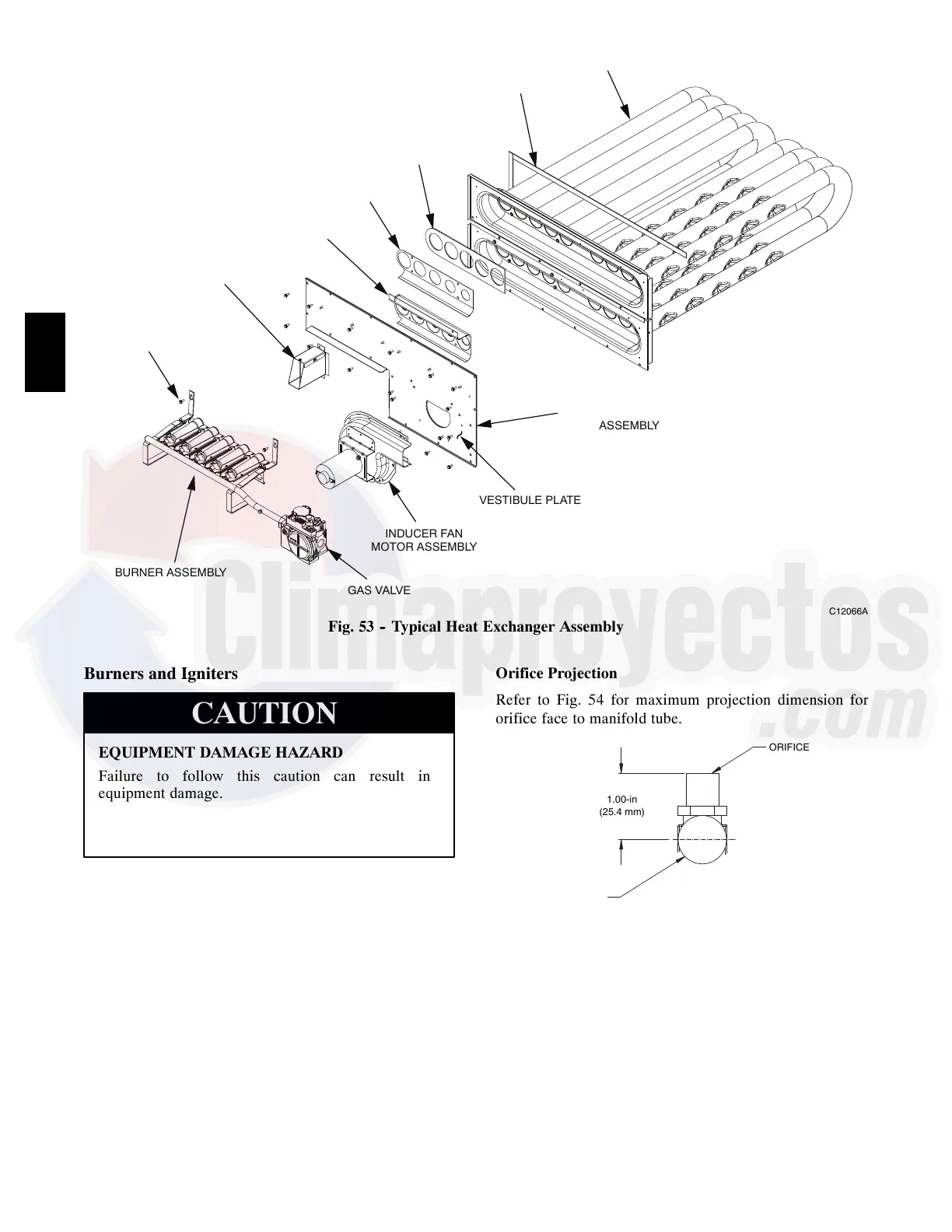

Orifice Projection

Refer to Fig. 54 for maximum projection dimension for

orifice face to manifold tube.

ORIFICE

1.00-in

(25.4 mm)

ANIFOLD

PIPE

C08211

Fig. 54 -- Orifice Projection

Removal and Replacement of Gas Train

See Figures 48, 53, and 55.

1. Shut off gas using the manual shutoff switch located

in the gas supply line.

2. Turn the gas valve ON/OFF knob to the OFF position.

3. Shut off power to unit and install lockout tag.

48HC

Loading...

Loading...