46

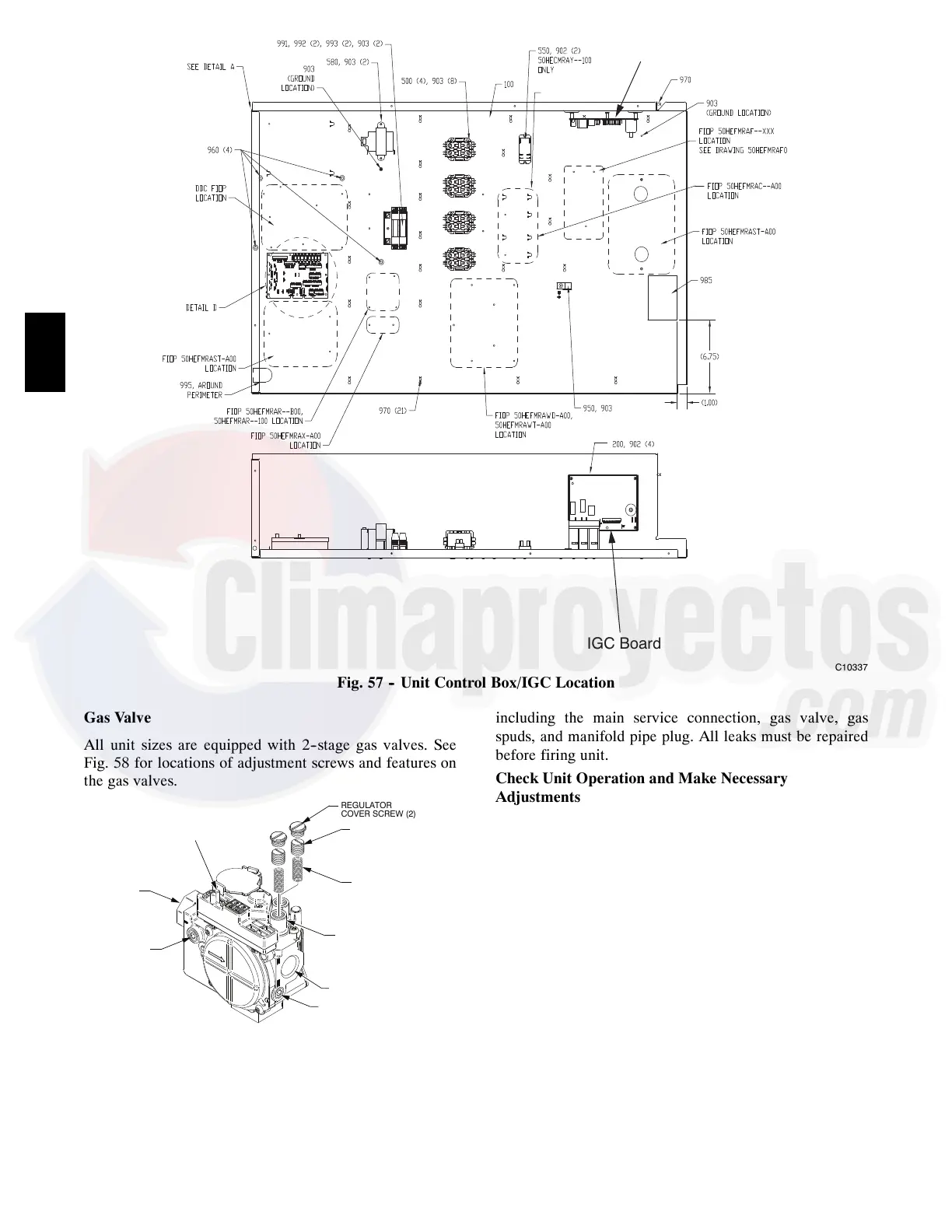

IGC Board

IGC Board

C10337

Fig. 57 -- Unit Control Box/IGC Location

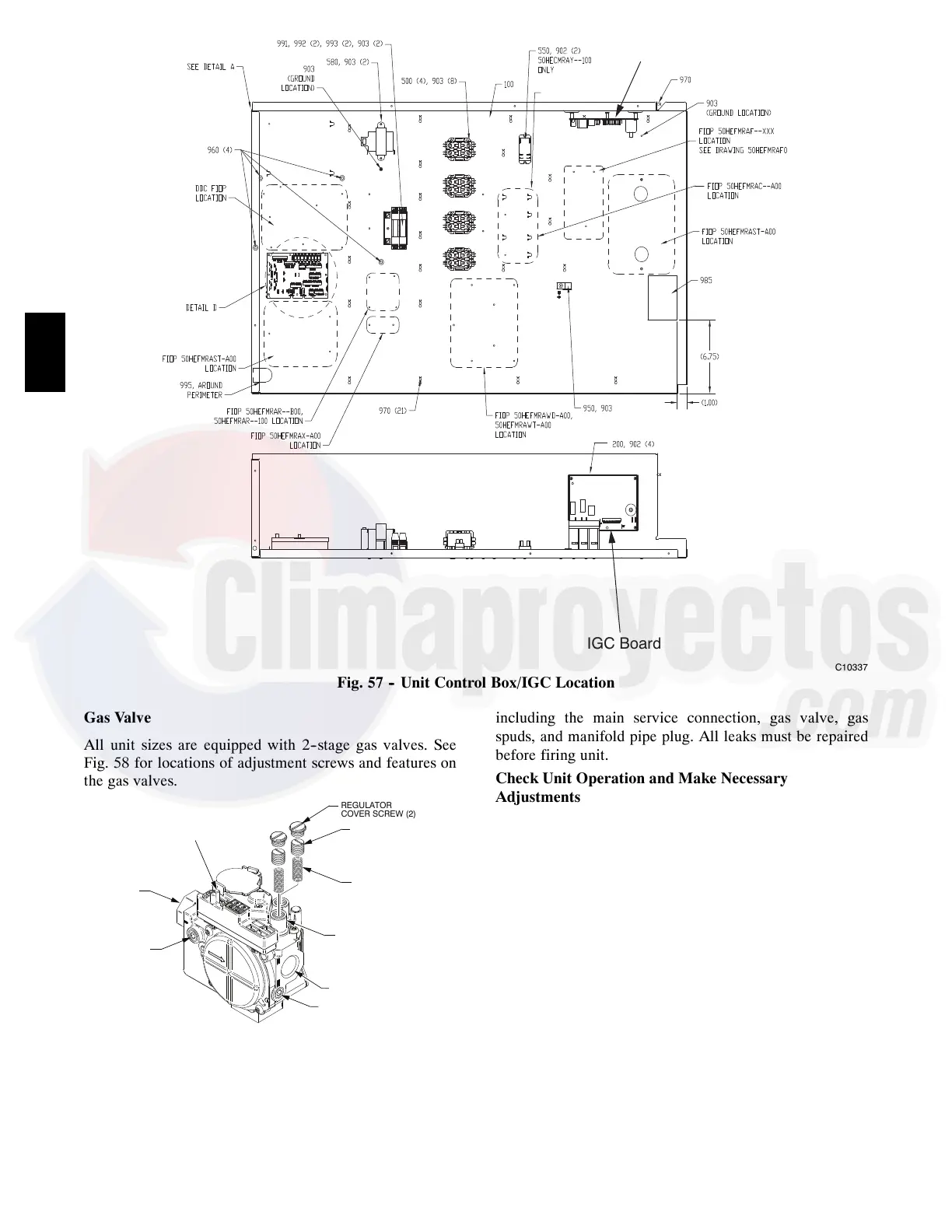

Gas Valve

All unit sizes are equipped with 2--stage gas valves. See

Fig. 58 for locations of adjustment screws and features on

the gas valves.

PLASTIC ADJUST

SCREW (2)

REGULATOR SPRING (2)

(PROPANE - WHITE

NATURAL - SILVER)

LOW STAGE

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF

SWITCH

REGULATOR

COVER SCREW (2)

NPT INLET

NPT OUTLET

C12066A

Fig. 58 -- Gas Valve

Adjusting Gas Valve Pressure Settings

IMPORTANT: Leak check (using a mixture of soapy

water or leak detection fluid) all gas connections

including the main service connection, gas valve, gas

spuds, and manifold pipe plug. All leaks must be repaired

before firing unit.

Check Unit Operation and Make Necessary

Adjustments

NOTE: Gas supply pressure at gas valve inlet must be

within specified ranges for fuel type and unit size. See

Tables 7, 8, 9, and 10.

1. Shut off electrical power supplies to unit and install

lockout tag.

2. Shut off manual gas shut off valve located on gas

supply line.

3. Remove manifold pressure tap plug from manifold

and connect pressure gauge or manometer. See Fig.

56.

4. Turn on electrical supply.

5. Open manual shut off valve, then turn on unit main

gas valve.

6. Set room thermostat to call for heat. Verify

high--stage heat operation before attempting to adjust

manifold pressure.

7. When main burners ignite, check all fittings,

manifold, and orifices for leaks.

48HC

Loading...

Loading...