50

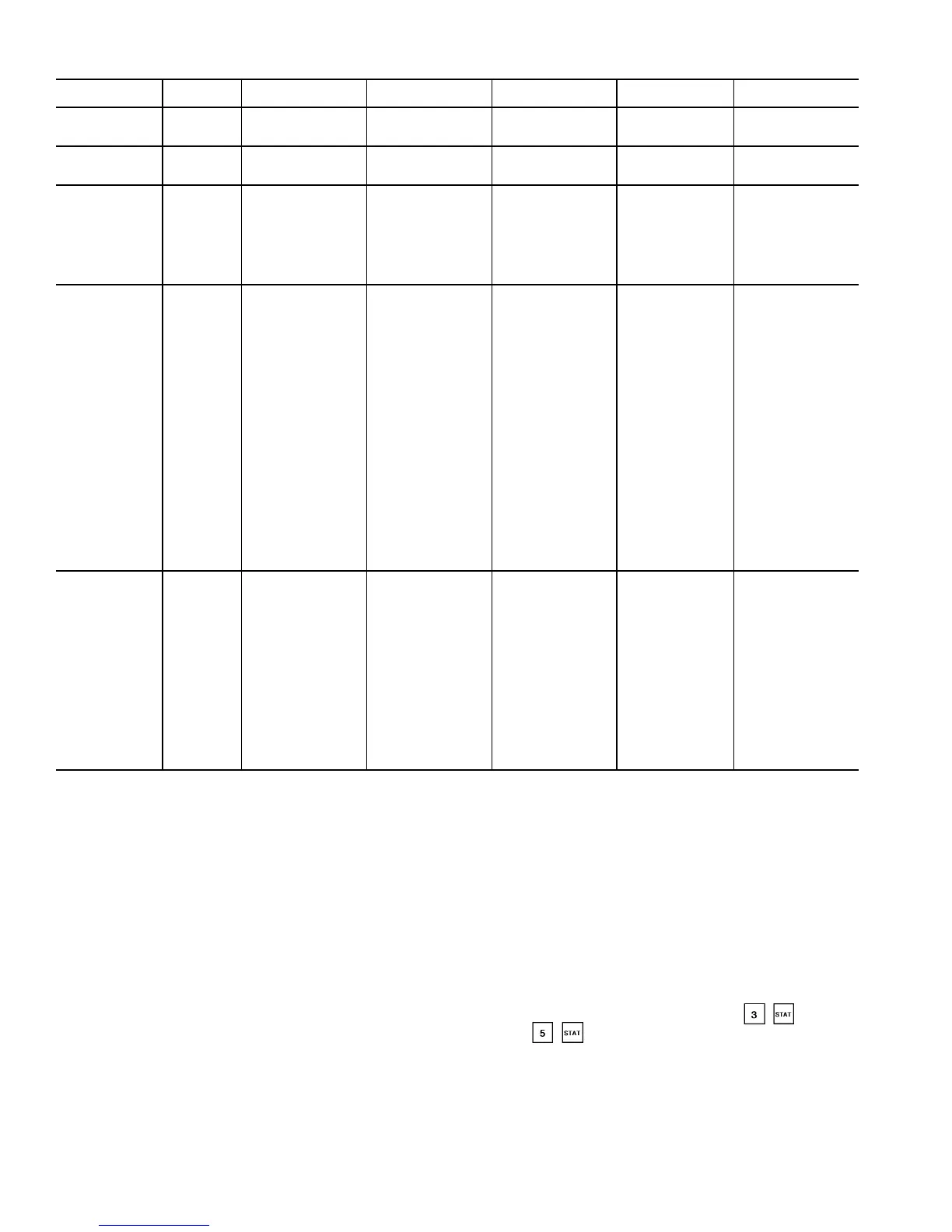

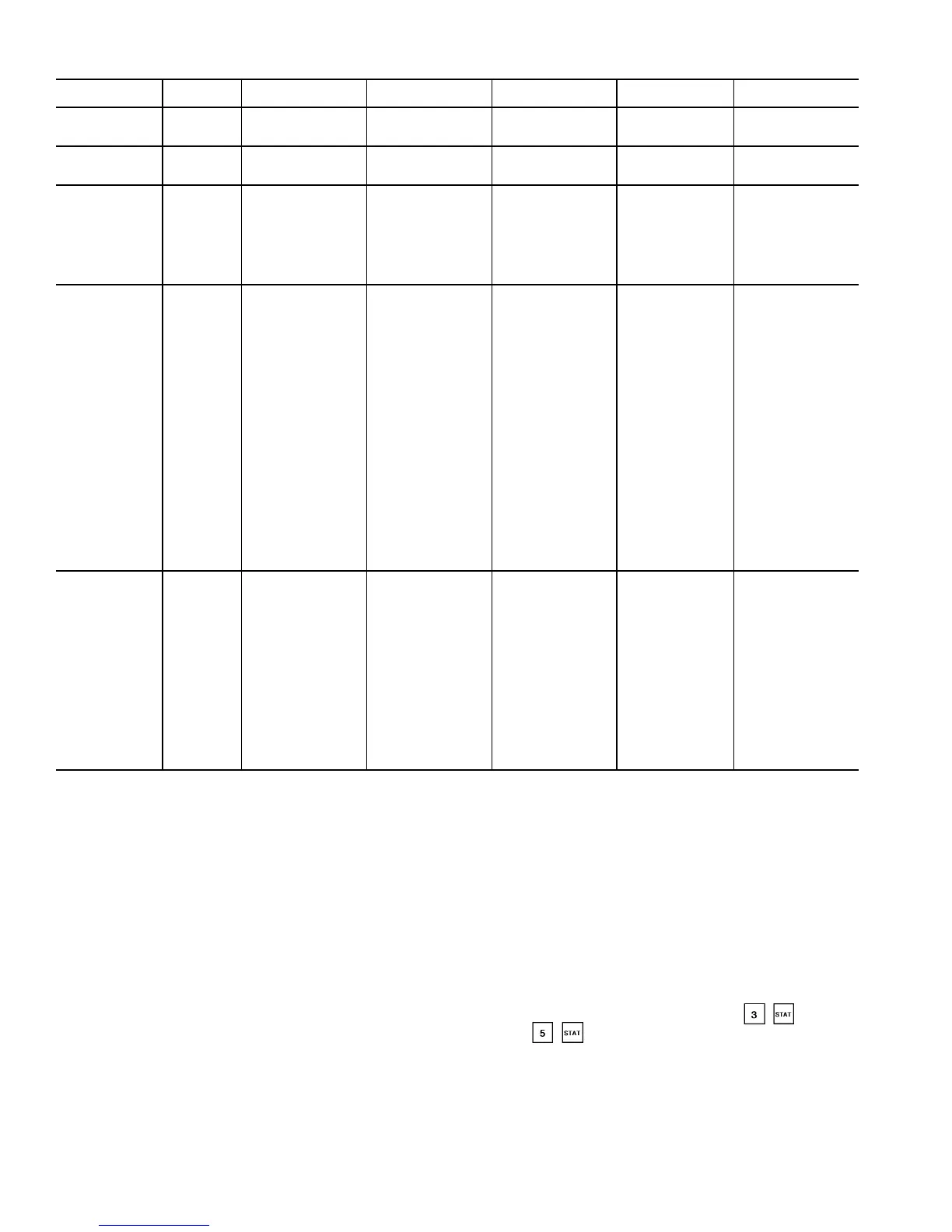

Table 36 — Alarm and Alert Codes (cont)

*Current imbalance alarm x.25 may be changed to warning x.27 after suc-

cessful start-up of the chiller.

†Compressors are equipped with 2 motor winding temperature thermistors.

Verify first that the problem is not a wiring error before using backup

thermistor.

**Reset automatic first time, manual if repeated on the same date.

††Note that the high-pressure switch should trip before this alert is generated.

Check HPS operation if this alert is generated.

NOTES:

1. Low Oil Pressure Alert Criteria and Set Points

Where: P

d

= Discharge Pressure, P

s

= Suction pressure,

P

o

= Oil pressure and P

e

= Economizer pressure

Two oil pressure set points are used. Oil Set point 1 is always 15 psig.

a. If (P

d -

P

s

) < 125, then Oil Set point 2 = 0.235 x (P

d -

P

s

) + 0.588

b. If (P

d -

P

s

) >= 125 and < 165, then Oil Set point 2 = 2.0 x (P

d -

P

s

) - 220.0

c. If (P

d -

P

s

) >= 165, then Oil Set point 2 = 0.6364 x (P

d -

P

s

) + 5.0

The 2 set points are used by the control for the Low Oil Pressure alert trip

criteria below:

a. Oil Pressure is ignored during the first 5 seconds after a compressor is

started.

b. In period between 5 and 120 seconds after starting, the alert will be gen-

erated if (P

o

- P

e

) < [(Oil Set point 1)/120] x (Compressor Run time in sec-

onds) for 3 consecutive readings

c. After 120 seconds of run time, the alert will be generated if:

1)(P

o

- P

e

) < Oil Set point 1 for 15 seconds OR

2)(P

o

- P

s

) < Oil Set point 2 for 25 seconds

2. (P

o

- P

e

) is the Oil pressure differential displayed in for Circuit A

and in for Circuit B.

ALARM/ALERT

CODE

ALARM OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM GENERATED?

ACTION TAKEN

BY CONTROL

RESET METHOD

PROBABLE

CAUSE

71 Alert Circuit A Low Oil

Level/Flow

Level switch input open

for 4th time in same day.

Circuit A shut down after

4th failure in 24 hours.

Manual Low oil level, failed

switch, wiring error,

failed DSIO module

72 Alert Circuit B Low Oil

Level/Flow

Level switch input open

for 4th time in same day.

Circuit B shut down after

4th failure in 24 hours.

Manual Low oil level, failed

switch, wiring error,

failed DSIO module

73 Alert Circuit A Low Discharge

Superheat

Superheat < 5 F (2.8 C)

for 10 minutes

Circuit A shut down Manual Faulty thermistor, trans-

ducer, or EXV, or Econo-

mizer. Motor cooling

solenoid stuck open.

74 Alert Circuit B Low Discharge

Superheat

Superheat < 5 F (2.8 C)

for 10 minutes

Circuit B shut down Manual Faulty thermistor, trans-

ducer, or EXV, or Econo-

mizer. Motor cooling

solenoid stuck open.

75 Alarm Comp. A1 Max. Oil

Delta P, check oil line

(Discharge press - Oil

press) > 100 PSI for

more than 5 seconds

Comp. A1 shut down Manual Plugged oil filter, closed

oil valve, bad oil sole-

noid, compressor oil

check valve stuck, oil line

check valve stuck,

plugged oil strainer

76 Alarm Comp. A2 Max. Oil

Delta P, check oil line

(Discharge press - Oil

press) > 100 PSI for

more than 5 seconds

Comp. A2 shut down Manual Plugged oil filter, closed

oil valve, bad oil sole-

noid, compressor oil

check valve stuck, oil line

check valve stuck,

plugged oil strainer

77 Alarm Comp. B1 Max. Oil

Delta P, check oil line

(Discharge press - Oil

press) > 100 PSI for

more than 5 seconds

Comp. B1 shut down Manual Plugged oil filter, closed

oil valve, bad oil sole-

noid, compressor oil

check valve stuck, oil line

check valve stuck,

plugged oil strainer

78 Alarm Comp. B2 Max. Oil

Delta P, check oil line

(Discharge press - Oil

press) > 100 PSI for

more than 5 seconds

Comp. B2 shut down Manual Plugged oil filter, closed

oil valve, bad oil sole-

noid, compressor oil

check valve stuck, oil line

check valve stuck,

plugged oil strainer

79 Alarm Comp. A1 Failed Oil

Solenoid

Diff. Oil pressure

> 2.5 PSI during period

after oil pump starts and

before oil solenoid opens

Comp. A1 not allowed to

start

Manual Faulty oil solenoid valve

80 Alarm Comp. A2 Failed Oil

Solenoid

Diff. Oil pressure

> 2.5 PSI during period

after oil pump starts and

before oil solenoid opens

Comp. A2 not allowed to

start

Manual Faulty oil solenoid valve

81 Alarm Comp. B1 Failed Oil

Solenoid

Diff. Oil pressure

> 2.5 PSI during period

after oil pump starts and

before oil solenoid opens

Comp. B1 not allowed to

start

Manual Faulty oil solenoid valve

82 Alarm Comp. B2 Failed Oil

Solenoid

Diff. Oil pressure

> 2.5 PSI during period

after oil pump starts and

before oil solenoid opens

Comp. B2 not allowed to

start

Manual Faulty oil solenoid valve

LEGEND

CCN — Carrier Comfort Network

CPM — Compression Protection Module

DGT — Discharge Gas Temperature

EWT — Entering Water Temperature

EXV — Electronic Expansion Valve

FSM — Flotronic™ System Manager

HPS — High-Pressure Switch

LCW — Leaving Chilled Water

LWT — Leaving Water Temperature

MCT_SP — Maximum Condensing Temperature Set Point

MTA — Compressor Must Trip Amps

SCT — Saturated Condensing Temperature

SST — Saturated Suction Temperature

W/C — Water-Cooled

WSM — Water System Manager

Loading...

Loading...