FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

26

Troubleshooting

For all flash codes, first try power cycling the system to remove the

code. Refer to Table 16 and Table 17.

No power

Verify the wiring to/from pins 1 and 8 on the power harness plug. Check

the 24V system wiring from the transformer.

Flashing 1

Check for refrigerant leaks using an independent R-454B detector. If no

leaks are present, replace the sensor.

Flashing 2

Check both ends of the sensor wire harness to ensure proper attachment.

Power cycle the system to check whether the flash code has been

removed. If the flash code is still present, replace the sensor.

Flashing 3

Check for refrigerant leaks using an independent R-454B detector.

Flashing 4

If the code does not clear after power cycling the system, replace the

dissipation board.

Flashing 5

If the code does not clear after power cycling the system, replace the

sensor.

Flashing 6

Press the test button repeatedly. Power cycle the system. If the button

cannot be reset, replace the dissipation board.

Flashing 7

Verify wiring of all "Y" and "W" wires in the applicable wiring diagram.

Flashing 8

Verify wiring of all "Y" and "W" wires in the applicable wiring diagram.

Care and Maintenance

To continue high performance, and minimize possible equipment failure,

it is essential periodic maintenance be performed on this equipment.

The ability to properly perform maintenance on this equipment requires

certain mechanical skills and tools. The only consumer service

recommended or required is filter maintenance (Filter Assembly on p27)

The minimum maintenance requirements for this equipment are as

follows:

1. Inspect and clean or replace air filter each month or as required.

2. Inspect cooling coil, drain pan, and condensate drain each cooling

season for cleanliness. Clean as necessary.

3. Inspect blower motor and wheel for cleanliness each heating and

cooling season. Clean as necessary.

4. Inspect electrical connections for tightness and controls for proper

operation each heating and cooling season. Service as necessary.

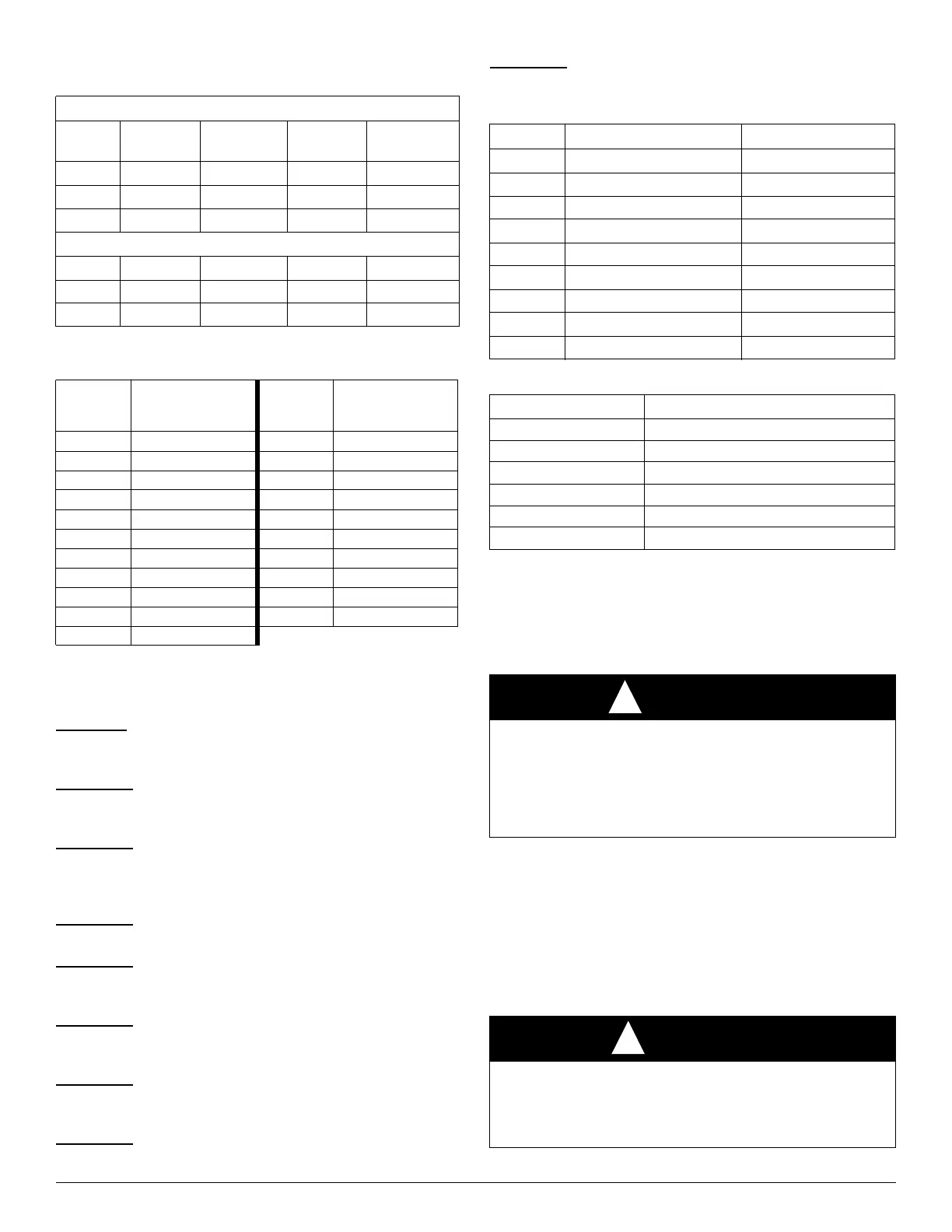

Table 14 – Required Operational Checks to Ensure Proper

Dissipation System Function

Normal Operation

Test # T-Stat Call Compressor Indoor Fan

Electric/Gas

Heat

1 None Off Off Off

2 Cool On On Off

3 Heat Off On On

Dissipation Activated

4 None Off On Off

5 Cool Off On Off

6 Heat Off On Off

Table 15 – Required Minimum Dissipation Mode Airflows,

based on Total System Refrigerant Charge Quantity

Total

System

Charge (lb)

Minimum Required

Dissipation Airflow

(CFM)

Total

System

Charge (lb)

Minimum Required

Dissipation Airflow

(CFM)

5 133 16 426

6 160 17 452

7 186 18 479

8 213 19 505

9 239 20 532

10 266 21 559

11 293 22 585

12 319 23 612

13 346 24 639

14 372 25 665

15 399

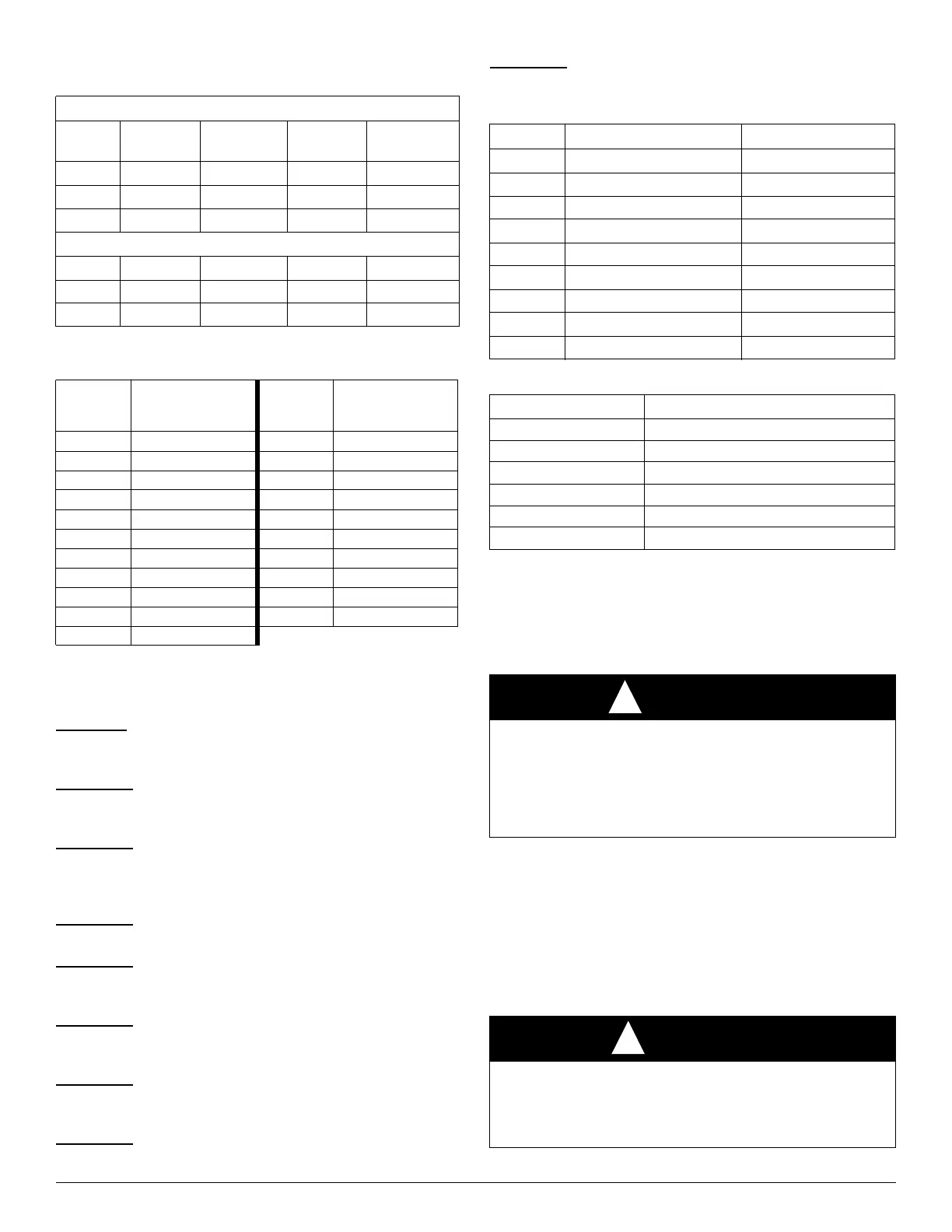

Table 16 – Flash Code Chart

Yellow LED Reason Mode

Solid Normal Operation Normal Operation

Flashing 1 Sensor >= 20% LFL Dissipation

Flashing 2 Sensor Open Dissipation

Flashing 3 Normal Mitigation after Leak Dissipation

Flashing 4 No Power to G Output Dissipation with no Blower

Flashing 5 Fault with A2L Digital Sensor Dissipation

Flashing 6 Test Button Stuck (>30 s) Dissipation

Flashing 7 Y or W Wiring Inverted Normal Operation

Flashing 8 Y or W Shorted Normal Operation

Table 17 – Wall-Hung FMA5 Control Board Test Functions

LED Status Description

Steady ON Normal Operation

OFF Power Supply Failure

Steady Flashing Dissipation Mode Active

3 Flash / Cycle A2L Sensor Error

4 Flash / Cycle A2L Sensor Communication Error

8 Flash / Cycle A2L Sensor Over Service Life

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Disconnect all power to the unit before servicing the field wires or

removing the control package. The disconnect (when used) on the

access panel does not disconnect power to the line side of the

disconnect, but does allow safe service to all other parts of the unit.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing and gloves when handling parts.

Loading...

Loading...