FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

19

4. Inspect electrical connections for tightness and controls for proper

operation each heating and cooling season. Service as necessary.

Filter Assembly

To clean or replace air filter, push plastic connectors toward center of

unit and remove filter access panel outward. Push filter up and back into

unit. Then slide filter out.

Clean filter by using cold water and mild detergent. Rinse and allow

filter to dry. No oiling or coating of filter is required.

New filters are available from your local distributor. Place filter in slot

with cross-mesh binding up or facing cooling coil and replace filter

access panel.

Cooling Coil, Drain Pan, and Condensate Drain

The cooling coil is easily cleaned when it is dry. Inspect the coil and

clean (if necessary) before each cooling season. To check or clean

cooling coil, remove coil access panel. If coil is coated with dirt or lint,

vacuum it with a soft brush attachment.

Be careful not to bend coil fins. If coil is coated with oil or grease, clean

it with a mild detergent and water solution. Rinse coil thoroughly with

clear water. Be careful not to splash water on insulation.

FFM and FMA

Fan Motor

The FFMANP (018,024,030,036), FMA4P and FMA5L motor is

three-speed PSC direct drive. High-speed lead is black, medium-speed

lead is red, low-speed lead is blue, and common lead is purple. The

FFMANP (019,025,031,037) and FMA4X/5Xmotor is a five speed

ECM direct drive. The cooling speed tap is selected by connecting the

green wire to the desired motor tap number indicated on the motor plug.

For the electric heat fan speed selection connect the white wire to the

desired motor tap number indicated on the motor plug. Be sure proper

blower speed has been selected.

The blower motor in this unit has blower-off delays. The blower-off

delay is 30–90 seconds and will keep the motor running after a heating

or cooling call ends.

The motor is turned on through two different routes. The first occurs

when thermostat calls for the fan in cooling, heat pump, or fan-only

mode. A 24VAC signal is sent to relay, causing relay to close its

normally open contacts, turning fan on.

The second occurs when there is a call for electric heat. A 24VAC signal

is sent to heater sequencer/relay, causing it to close, directing 230V

through the normally closed contact of fan relay, turning fan on. The fan

remains on until sequencer/relay/PCB opens.

FMA5 only—has a third way to start the fan motor. If the dissipation

system detects a refrigerant leak, G is energized and completes the

circuit to the indoor blower motor.

If motor does not run, test motor for an open winding or a winding

shorted to motor case. If either is present, replace motor.

Time Delay

FFMANP (019,025,031,037) and FMA4X/5X have time delay built into

the motor logic. FFMANP (018,024,030,036), FMA4P and FMA5L

units with date codes prior to 1715V have sequencers. FFMANP

(018,024,030,036), FMA4P and FMA5L units with date codes 1715V or

later have a time delay printed circuit board.

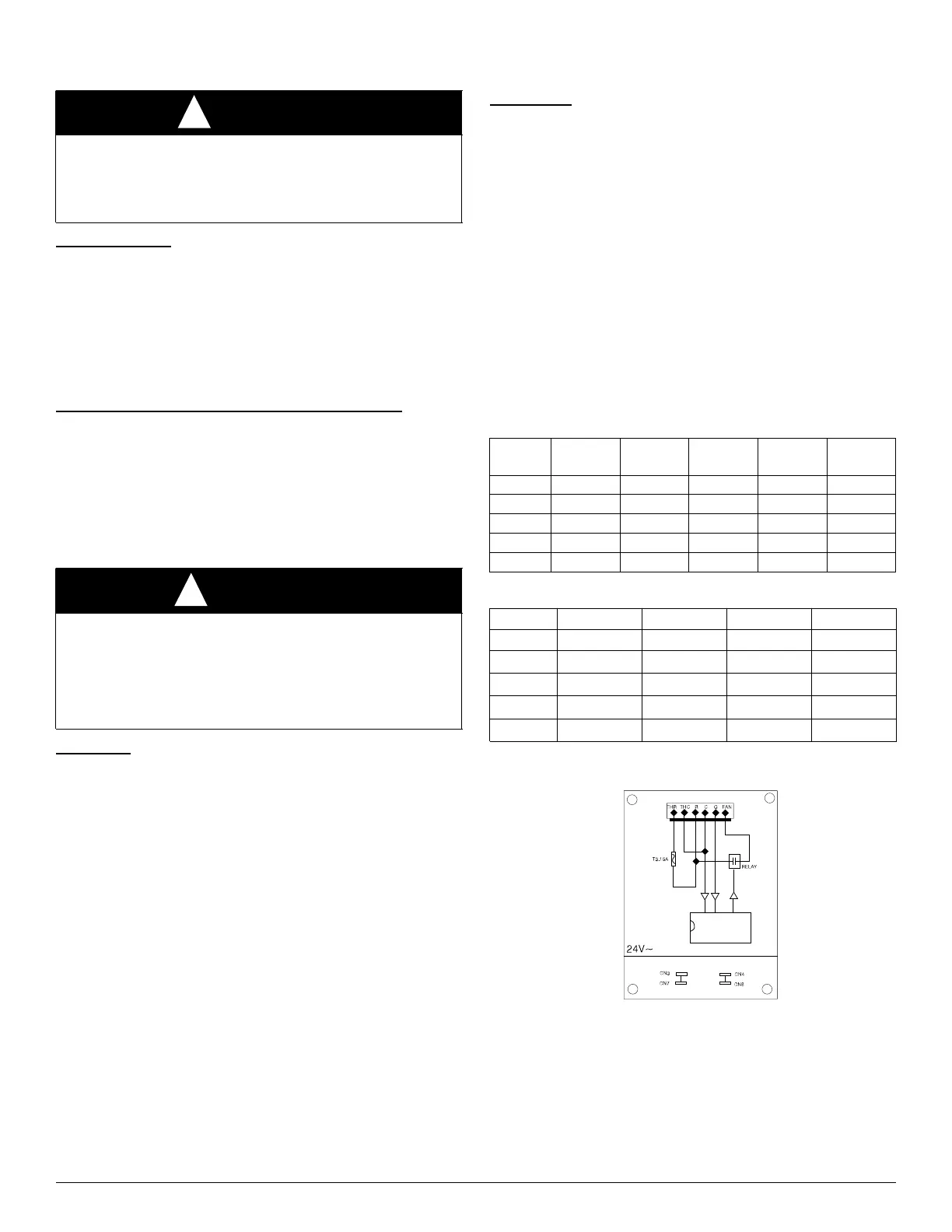

The Time Delay Printed Circuit Board (PCB) s a logic controlled time

delay activated by low-voltage control signal (G) from thermostat. The

PCB includes a normally open relay which closes to energize the blower

motor when the G terminal is energized. Then when the G terminal is

de-energized the relay energizing the blower motor remains closed for

90–100 seconds before opening.

NOTE: Aluminum coil models with PSC motor can be wired to

different OFF time delay. See installation instructions for wiring

diagram.

FMA5X units have time delay built into the motor logic. See the Motor

Speed Taps table in the installation instructions. FMA5L have the time

delay functionality integrated into the control board.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing and gloves when handling parts.

WARNING

!

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury or death.

Before installation or servicing system, always turn off main power to

system. There may be more than one disconnect switch. Turn off

accessory heater power if applicable. Lock out and tag switch with a

suitable warning label.

Table 11 – Speed Tap and Off -Delay Time (FMA4)

Speed

Tap

Off-Delay

Time

18 24 30 36

Tap 1 30 - - - -

Tap 2 90 Default - Default -

Tap 3 30 - - - -

Tap 4 90 - Default - Default

Tap 5 30 - - - -

Table 12 – FMA5X ECM Motor Speed Taps Delay Off Time Setting

Tap 18 24 30 36

Tap 1

30 30 30 30

Tap 2

30 30

30/90

*

*. Default setting

Where two numbers are shown, left represents Minor series 1 and right

represents Minor series 2.

A150455B

Fig. 1 – Time Delay PCB Schematic

30/90

Tap 3

90

*

90 90/30 90/30

Tap 4

90/0 90/0 90

90

*

Tap 5

90

90

*

90/0 90/0

Comments:

1. The THR and THC are connected to transformer output.

2. When the G has signal, the FAN will supply 24VAC power

to control fan relay.

3. Whe the G signal is gone, the FAN will stop 24 VAC output

after 90 seconds.

4. CN3, CN7 are dummy connection terminals.

Loading...

Loading...