FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

18

ADVANCED TROUBLESHOOTING:

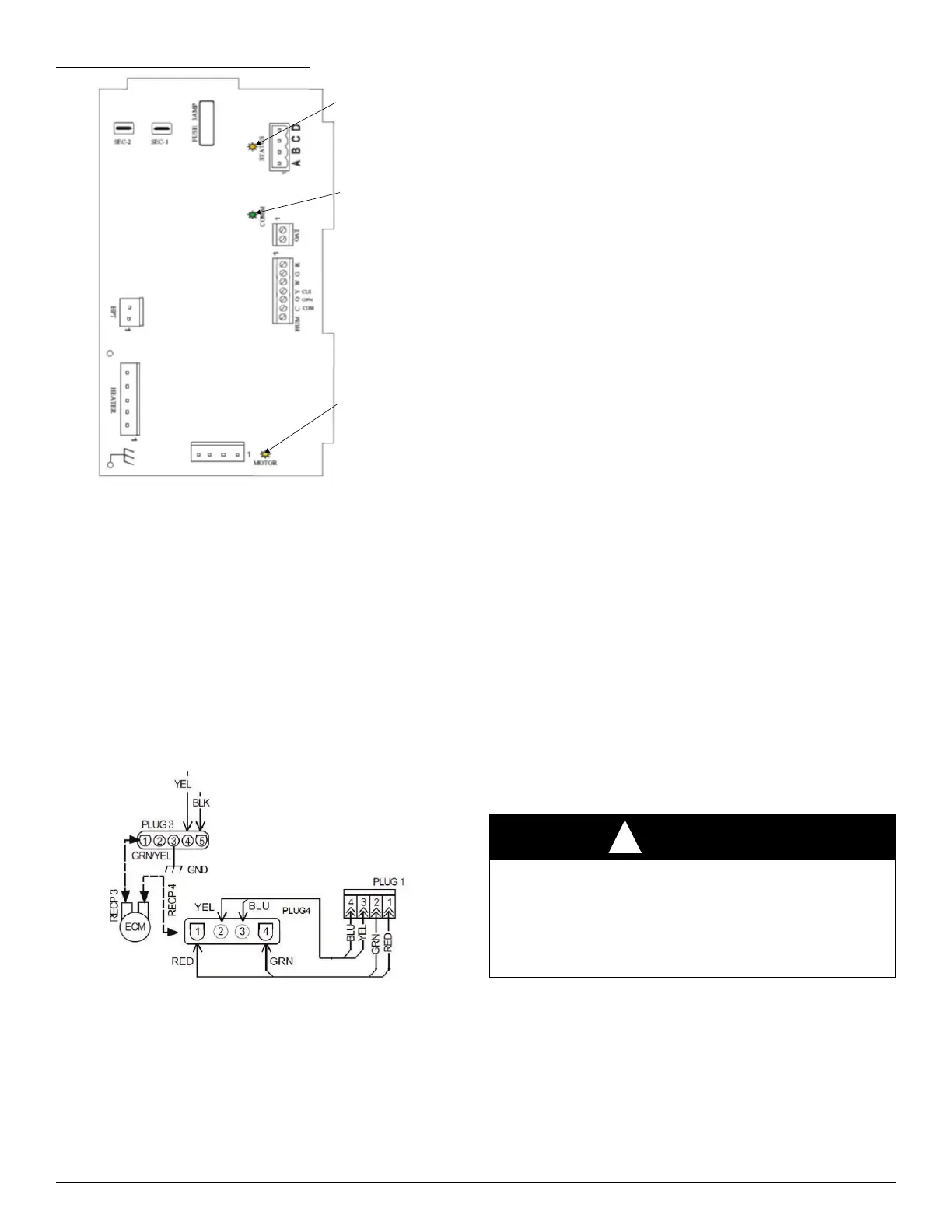

A13030

Fig. 14 – Circuit Board LED Locations

Troubleshooting the FE4/FE5 Fan Coil Circuit Board:

– Production Unit circuit board Fan Coil part number HK38EA061

– RCD Replacement circuit board HK38EA061

– Older circuit board part numbers HK38EA006, HK38EA009, and

HK38EA011

Primary test that should be performed:

Motor Line Voltage Check

1. Turn off power (240V).

2. Remove Plug 3 from ECM motor

3. Turn on power.

4. Check Plug 3, terminals 4 and 5, to ensure there are 240V.

5. Turn off power.

6. Reconnect Plug 3 to motor.

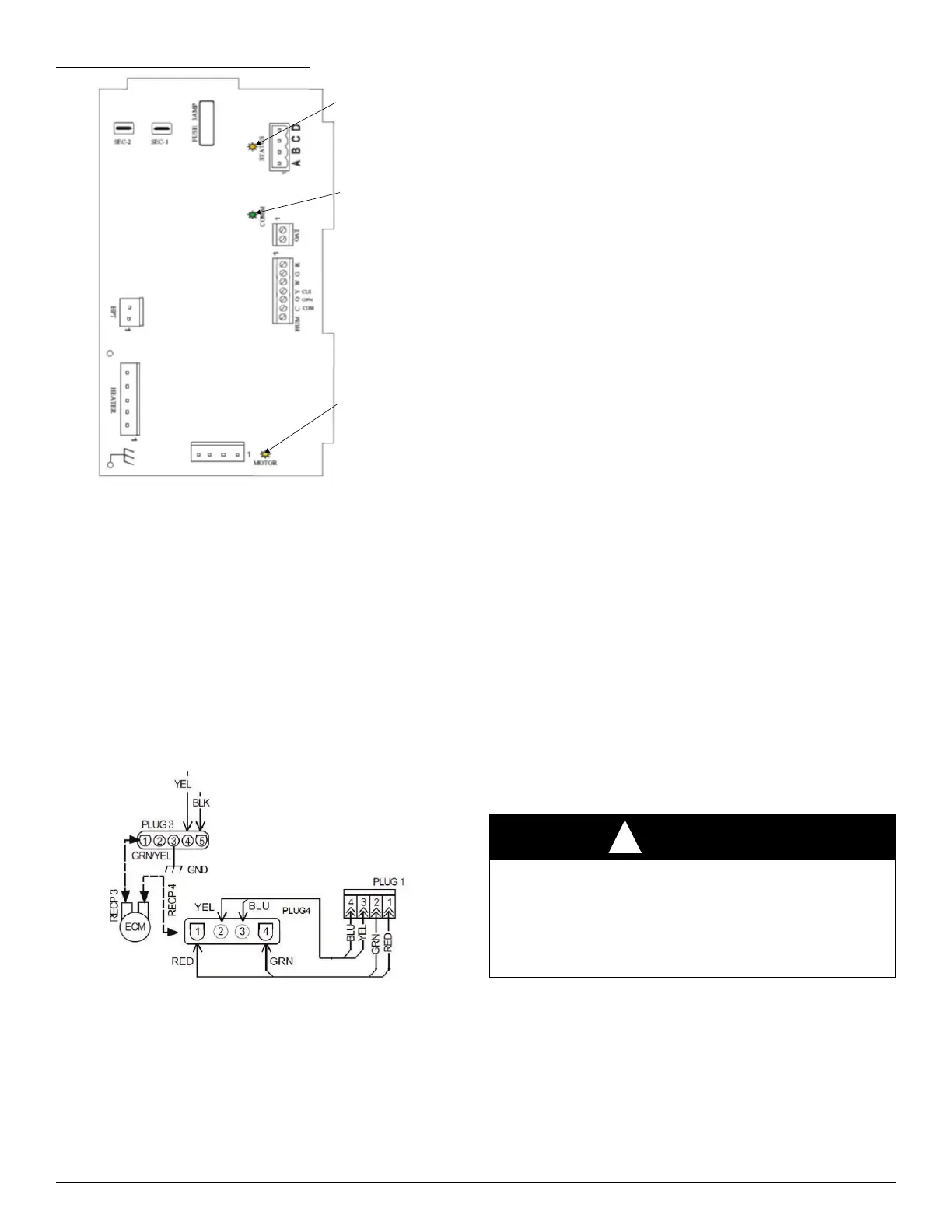

A13031

Fig. 15 – ECM / Plug Wiring Diagram

The following troubleshooting techniques will assist in determining the

correct component to replace when the Fan Coil Board presents a Fault

Code 44 or 41:

1. Disconnect power from the unit (240V).

2. Disconnect the ABCD connector from the board.

3. Disconnect Plug 1 from the board (Fig. 15).

4. Turn on power (240V).

5. After reestablishing power, you should receive Fault Code 44, and

the motor LED should be off.

6. Place a jumper across the R and G terminals on the low voltage

terminal block

7. Fault Code 44 should still be flashing.

8. The Motor LED should be flashing, indicating the board is able to

transmit a signal to the motor.

9. If Motor LED is not flashing, check to ensure that 24V is present

across R and C on the low voltage terminal block and that there is a

good connection with the R and G jumper.

10. If 24V is present and the jumper/connections are good,

11. Replace the board.

Check Board

1. If Fault Code 44 and the Motor LED are both flashing, place a DC

voltmeter across terminals PL1-1 Red (+) to PL1-2 Green (-)

(Fig. 15).

2. Across terminal PL1-1 and PL1-2, a 12VDC should be present. If

12VDC is not present, replace circuit board.

3. If Fault Code 44 is flashing and the Motor LED is flashing, place a

DC voltmeter across terminal PL1-3 (+) and PL1-2 (-).

4. Across terminal PL1-3 (+) and PL1-2 (-), the DC volt meter should

display 5VDC. The voltage should be very stable and should not

fluctuate more than 0.02VDC. If the voltage fluctuates, get a

different voltmeter before proceeding to the following steps.

5. Reconnect Plug 1 to circuit board and connect DC voltmeter across

terminals PL1-3 Yellow (+) and PL1-2 Green (-). Does the voltage

appear to fluctuate more than in step 15? Typical voltmeters will

show a fluctuation of 0.2VDC to 1VDC. The amount of fluctuation

is not important. You could see even more fluctuation depending on

the voltmeter used.

6. Check the blower motor serial output signal. The blinking LED on

the control board represents the serial output signal. You can

measure the signal with a DC voltmeter by removing Plug 1 from

the circuit board and connecting the DC voltmeter across PL1-4 (+)

and PL1-2 (-). The voltage should be near 0VDC but it will

fluctuate briefly several times per second. If you have an analog

voltmeter, the needle briefly will go high several times per second.

If you have a digital voltmeter with a bar graph, it will show a large

change in magnitude on the bar graph several times per second. If

you have a plain, digital voltmeter, it will show a brief fluctuation

in voltage, and the magnitude may vary depending on the voltmeter

used.

The minimum maintenance requirements for this equipment are as

follows:

1. Inspect and clean or replace air filter each month or as required.

2. Inspect cooling coil, drain pan, and condensate drain each cooling

season for cleanliness. Clean as necessary. An inspection port is

provided on all A-coil delta plates. Remove plastic plug to inspect.

Replace plug after inspection.

3. Inspect blower motor and wheel for cleanliness each heating and

cooling season. Clean as necessary.

Status

LED

Communication

LED

Motor

LED

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Disconnect all power to the unit before servicing the field wires or

removing the control package. The disconnect (when used) on the

access panel does not disconnect power to the line side of the

disconnect, but does allow safe service to all other parts of the unit.

Loading...

Loading...