FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

31

Before installation of replacement coil, verify the piston is the correct

orifice size. The correct size should be on the outdoor unit rating plate. If

in doubt, reuse the piston from the old indoor coil.

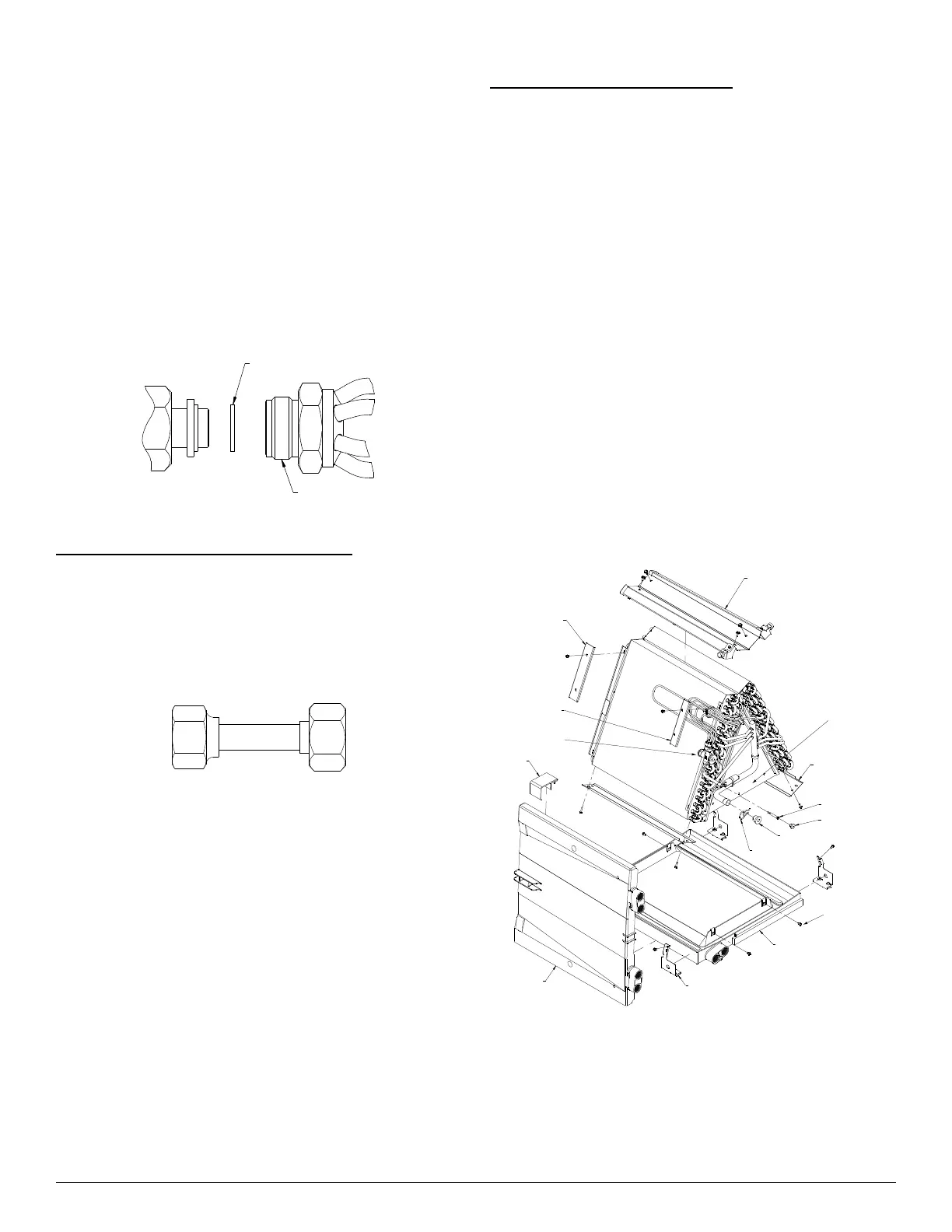

Use two wrenches to separate the 13/16" Chatleff nut from the

distributor body. The threads will contain Loctite anti-seize, do not

remove this from the threads.

Install the piston and reattach nut to finger tight plus 1/2 turn.

The distributor used on the all-aluminum replacement coil is also made

of aluminum. The distributor threads are coated with Loctite Heavy

Duty Anti-Seize which is a graphite/calcium fluoride formulation, for

applications that are free from copper, lead and sulfur. This product is

typically used in applications with an operating range of -20° F to

+2400° F (Fig. 29). When replacing a TXV it is recommended to reapply

with the same thread sealer. Extra care should be taken during brazing of

copper equalizer on the aluminum coils to prevent the braze material

from splattering on the aluminum. Also, route the copper equalizer so

that it doesn’t touch the aluminum components.

A14398

Fig. 29 – TXV Thread (Sealer) Location

Old Copper or Tin-Plated Coils with TXV

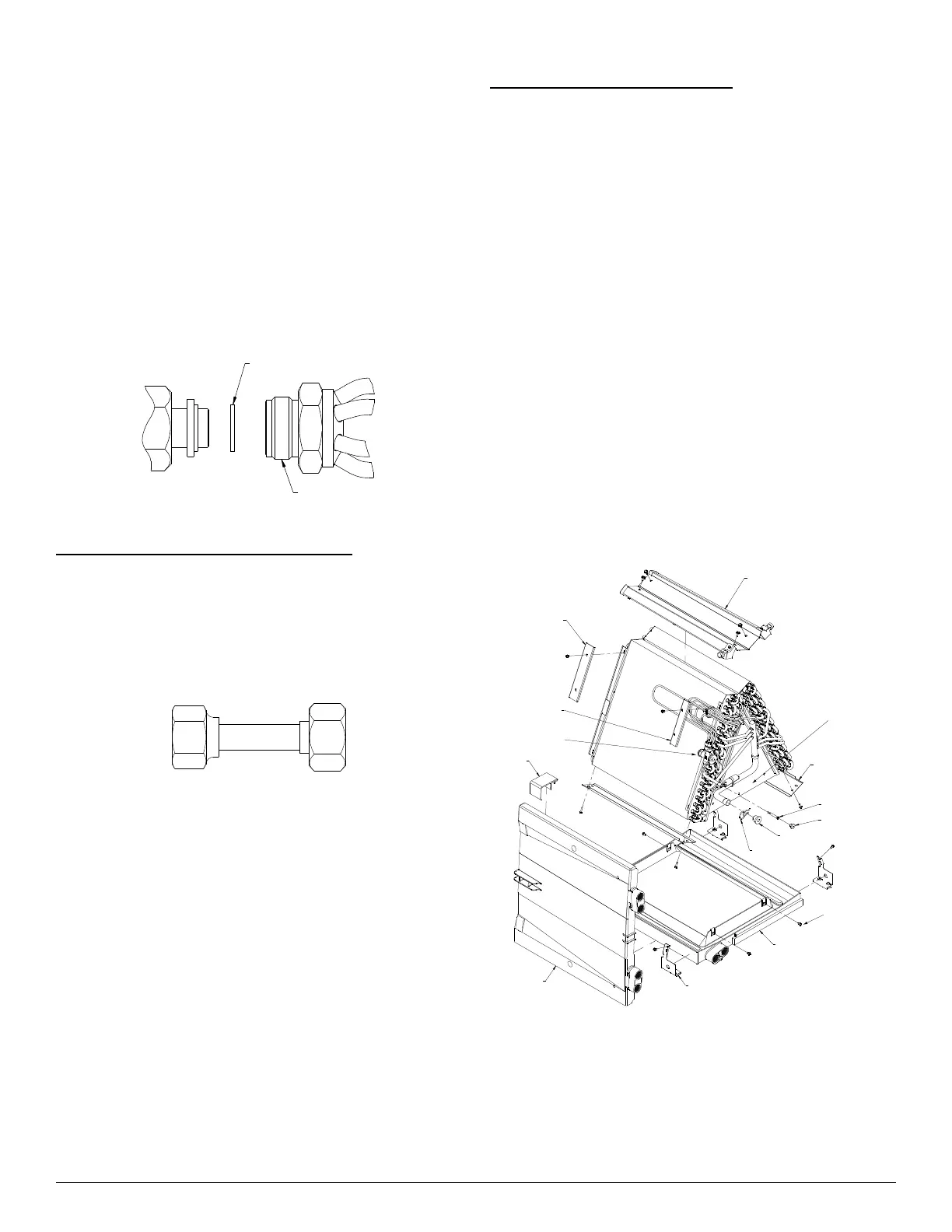

The all-aluminum replacement coil with piston will also be used for

TXV style coils by reusing the original TXV. An adapter is provided to

connect the replacement coil distributor to the original TXV (Fig. 30).

Insulation is also provided to wrap the copper adapter tube and brass

nuts to prevent any copper or brass particles from coming in contact with

the aluminum coil. Even if the adapter tube is not in contact with the

aluminum coil dripping condensation from the adapter tube can be a

mechanism of particulate transport.

A14397

Fig. 30 – Replacement Coil Distributor Adapter

If it is preferred to install the old TXV external to the cabinet due to

access, follow the steps below:

1. Field fabricate a piece of 3/8" OD copper tubing with flare and nut

to attach to the TXV outlet.

2. The piston in the replacement coil must be removed. Use two

wrenches to separate the 13/16" Chatleff nut from the distributor

body. The threads will contain Loctite anti-seize, do not remove this

from the threads.

3. Remove the piston

4. Reattach the inlet tube and tighten the nut finger tight plus 1/2 turn.

5. Remove the old coil and install replacement coil per instructions

below. Reinstall the fitting door to the cabinet.

6. Field fabricate a 3/8" OD copper tubing with flare and nut.

7. Braze this tubing and nut onto the liquid stub out.

8. Attach flare and nut to TXV outlet by tightening to finger tight plus

1/2 turn with two wrenches.

9. Drill equalizer hole into suction line and braze the equalizer into the

hole.

10. Attach the TXV bulb onto the suction line and insulate.

11. Insulate the entire TXV body and outlet tubing to prevent sweating.

Old All-Aluminum Coils with TXV

When replacing a previous all-aluminum coil that contains a TXV, the

old TXV can be reused and mounted inside the cabinet.

1. After removal of the distributor inlet tube and piston, the old TXV

is attached to the distributor with 13/16" Chatleff nut. The threads

contain Loctite anti-seize that can be reused.

2. Tighten the nut finger tight plus 1/2 turn.

3. The vapor header contains a small diameter stub tube for the

equalizer line.

4. Cut the end of the stub tube.

5. Insert TXV equalizer and braze together. Caution must be taken to

avoid braze splatter from the aluminum surfaces of the new coil.

Caution must be taken to avoid heating the factory joint of the stub

tube to the vapor header.

6. The vapor header contains an indentation for the TXV bulb. Attach

the bulb and insulate.

Installation – A-Coil Units Only

1. Recover system refrigerant.

a. Attach gage/manifold set to service valves.

b. Start unit in cooling mode.

c. Front seat (close) liquid line service valve.

d. Operate unit until vapor pressure reaches 5 psig (35kPa), or until

suction line LPS opens.

e. Turn off electrical supply to outdoor unit.

f. Front seat (close) vapor service valve.

g. Recover any remaining refrigerant.

A13359

Fig. 31 – A-Coil Component Location

NOTE: All condenser coils hold only a factory-supplied amount of

refrigerant. Excess refrigerant, such as in long-line applications, may

cause compressor internal pressure relief valve to open (indicated by

sudden rise in vapor pressure) before refrigerant is recovered. If this

occurs, turn off electrical supply to outdoor unit immediately, front seat

(close) vapor service valve, and recover any remaining refrigerant.

2. Turn off electrical supply to indoor unit.

Cond. Trough

Coil Top Seal

Pan Shield

(2 per unit)

Coil Bracket

(4 per unit)

Vertical Condensate Pan

Horizontal

Condensate Pan

Strainer

Rubber Plug

Rubber Plug

Support

Cond. Trough

Drip Ring

TXV

Delta Plate

Screws-

Delta Plate To Pan

(4 per unit)

Loading...

Loading...