FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

6

A13028

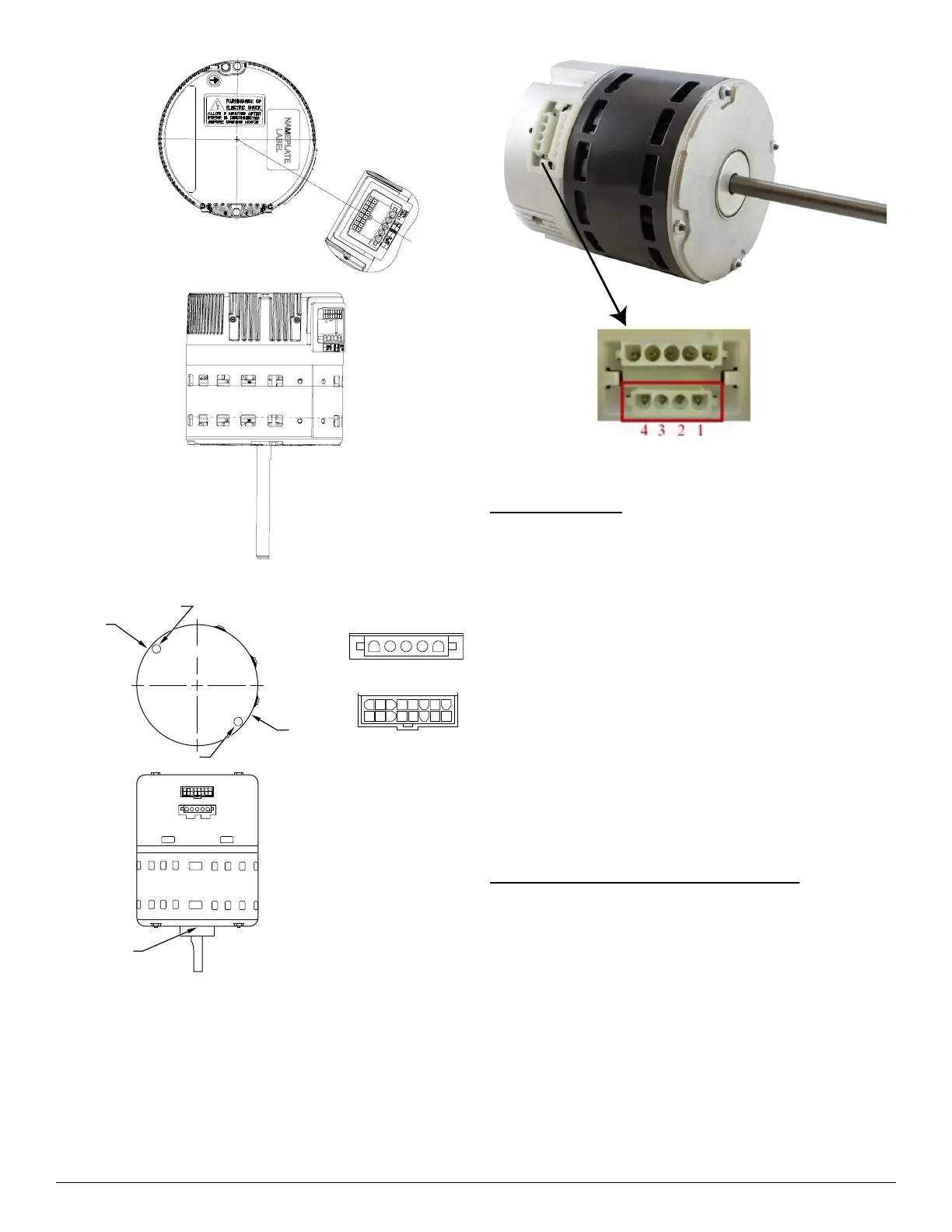

Fig. 5 – FV4 Motor / ECM5.0 Motor (pre-2023)

A98201

Fig. 6 – FV4 Motor / ECM2.3 Motor (pre-2023)

A230463

Fig. 7 – ECM Motor, post-2023

FV, FT4, FG4

Constant Air Flow

Unlike fan coils using induction motors where static pressure affects

airflow, these fan coils are constant airflow units. The blower delivers

requested airflow regardless of static pressure. Consult fan coil Product

Data for static pressure limits. The ECM2.3/5.0 is pre-programmed and

contains airflow tables for all modes of operation. Blower characteristics

(requested airflow, torque, and speed) are known from laboratory testing

If any two characteristics are known, the third is defined.

Requested airflow is known from Easy Select board configuration and

thermostat signals. Torque is known because it is directly related to

stator current, which is measured by motor control. Speed is measured

by counting back EMF pulses from stator windings. This information is

entered into an expression that calculates torque from speed and airflow

numbers. If calculation does not match stored blower characteristics,

torque is adjusted until agreement is reached. This calculation and

adjustment is performed every 0.8 seconds while motor is in operation.

There is no direct measure of static pressure, but unit does react to a

change in static to maintain constant airflow. A change in pressure will

result in a change in stator speed and torque. The motor will begin to

adjust on the next sampling, calculate new desired speed and torque, and

adjust as necessary.

Integrated Controls and Motor ECM2.3/5.0

An ECM2.3/5.0 is fed high voltage AC power through the 5-pin

connector (Fig. 6 or Fig. 5). The AC power is then internally rectified to

DC by a diode module. After rectification, DC signal is electronically

communicated and fed in sequential order to three stator windings. The

frequency of these commutation pulses determines motor speed. The

rotor is permanently magnetized.

An ECM2.3/5.0 is powered with high voltage at all times. The motor

will not run with high voltage alone. Low voltage must be applied to

control plug to run motor.

ECM2.3/5.0 Control Power

The ECM2.3/5.0 control power is supplied from R circuit through

printed circuit runs to motor control Connector-Pin 8, through motor

control harness to motor. The C side of low-voltage control power circuit

is connected by printed circuit runs to motor Connector pins 9, 10, and

11, then through motor control harness to motor.

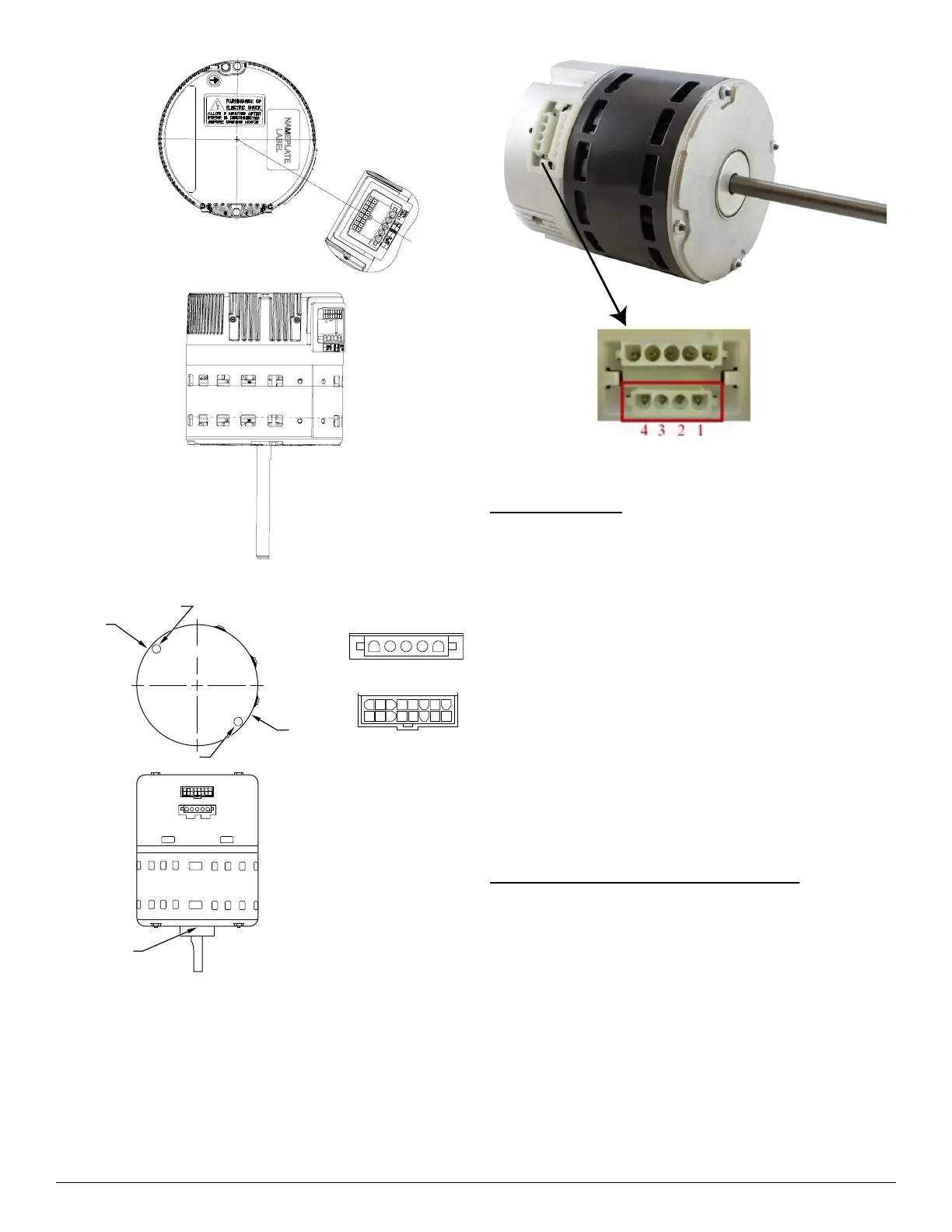

12345

9

12345678

10 11 12 13 14 15 16

POWER CONNECTOR

CONTROL CONNECTOR

OPTIONAL SAFETY GROUND

DRAIN HOLE

DRAIN HOLE

OPTIONAL SAFETY GROUND

ENDSHIELD

DRAIN HOLE

CONTROL

POWER

Loading...

Loading...