4

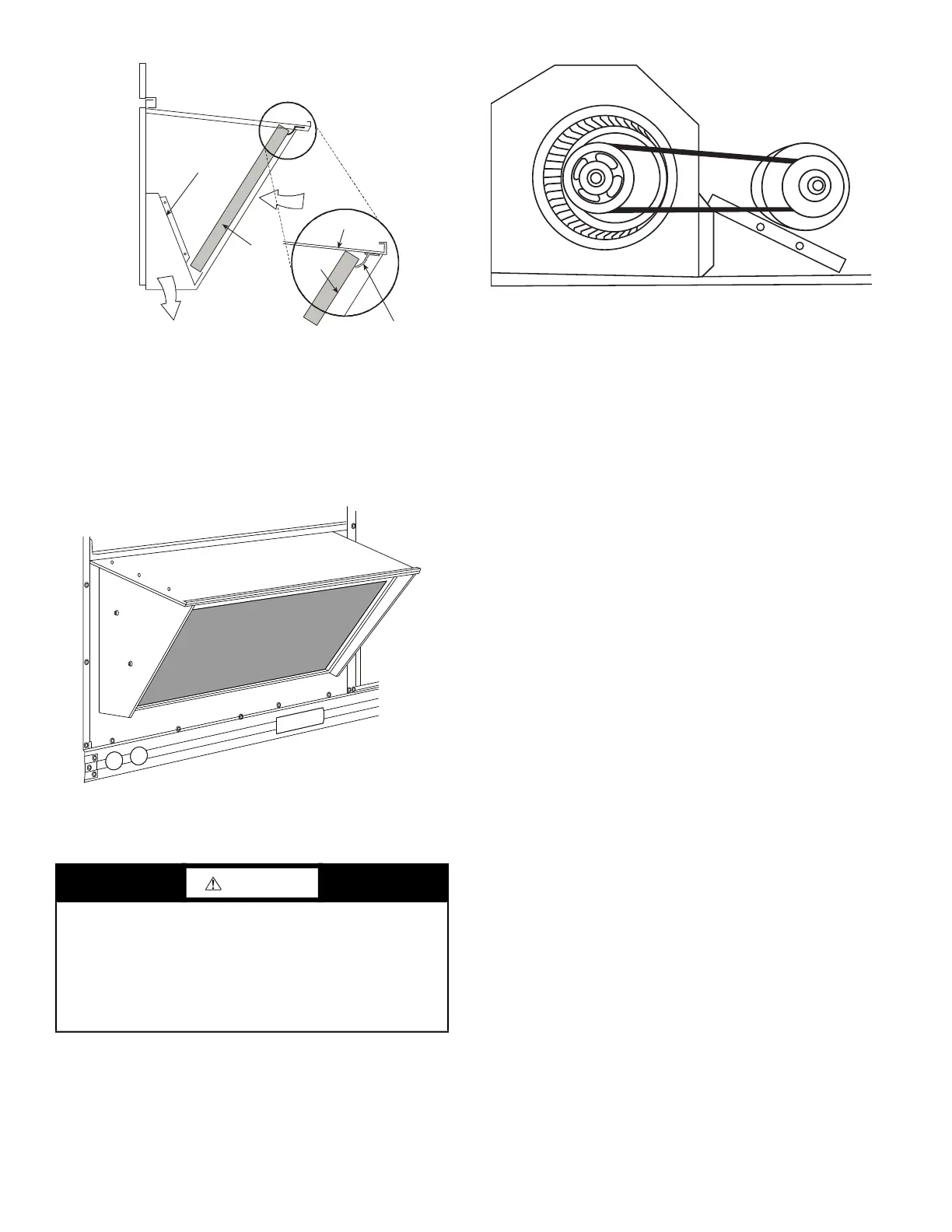

Fig. 3 — Filter Installation

MANUAL OUTSIDE AIR HOOD SCREEN

This inlet screen is secured by a retainer angle across the top edge

of the hood. (See Fig. 4.)

To remove the screen, loosen the screws in the top retainer and slip

the retainer up until the filter can be removed. Re-install by plac-

ing the frame in its track, rotating the retainer back down and

tighten all screws.

Fig. 4 — Screens Installed on Outdoor-Air Hood

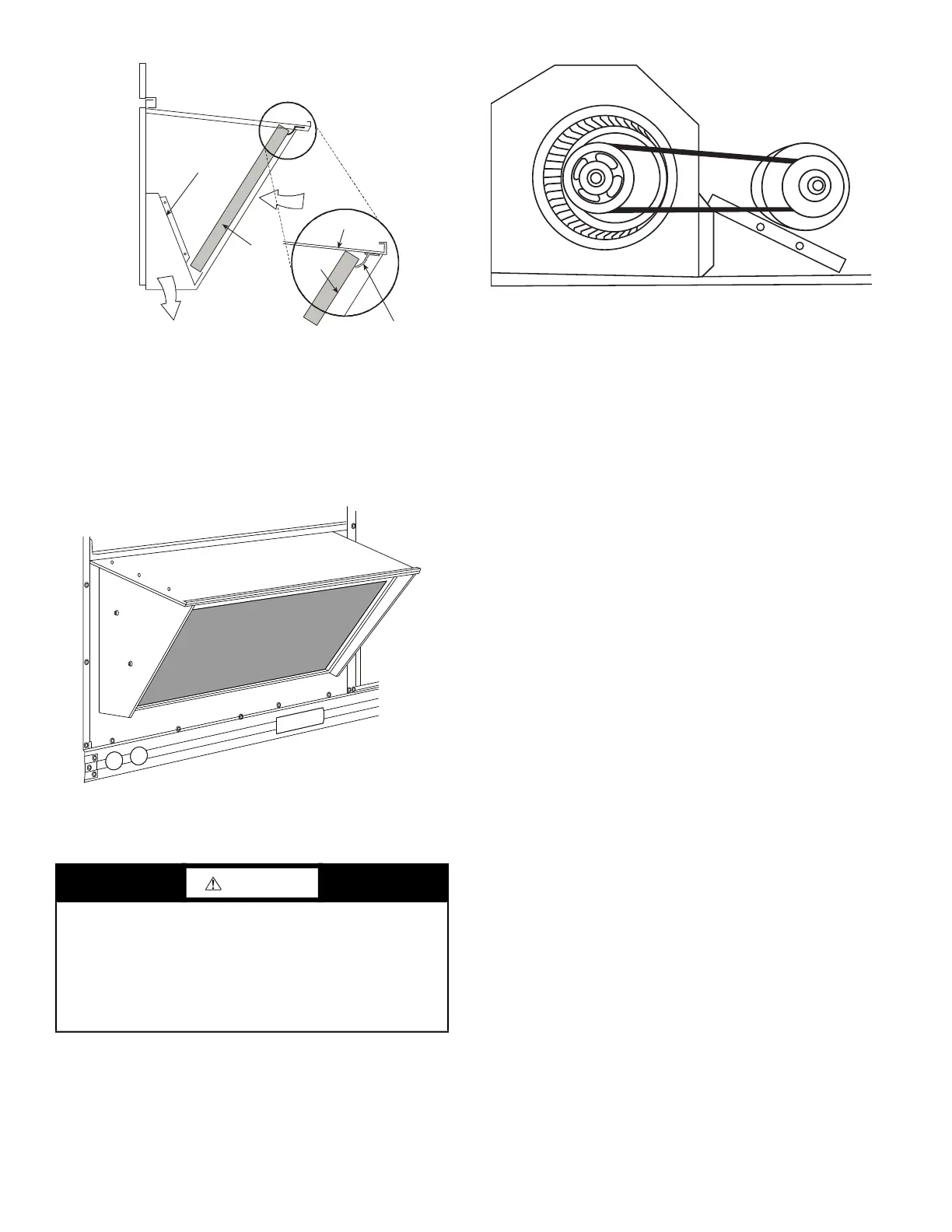

SUPPLY FAN (BLOWER) SECTION

Supply Fan (Belt-Drive)

The supply fan system consists of a forward-curved centrifugal

blower wheel on a solid shaft with two concentric type bearings,

one on each side of the blower housing. A fixed-pitch driven pul-

ley is attached to the fan shaft and an adjustable-pitch driver pulley

is on the motor. The pulleys are connected using a “V” type belt.

(See Fig. 5.)

Fig. 5 — Belt Drive Motor Mounting

BELT

Check the belt condition and tension quarterly. Inspect the belt for

signs of cracking, fraying or glazing along the inside surfaces.

Check belt tension by using a spring-force tool (such as Brown-

ing’s Part Number “Belt Tension Checker” or equivalent tool);

tension should be 6 lb at a

5

/

8

-in. deflection when measured at the

centerline of the belt span. This point is at the center of the belt

when measuring the distance between the motor shaft and the

blower shaft.

NOTE: Without the spring-tension tool, place a straight edge

across the belt surface at the pulleys, then deflect the belt at mid-

span using one finger to a

1

/

2

-in. deflection.

Adjust belt tension by loosening the motor mounting plate front

bolts and rear bolt and sliding the plate toward the fan (to reduce

tension) or away from fan (to increase tension). Ensure the blower

shaft and the motor shaft are parallel to each other (pulleys

aligned). Tighten all bolts when finished.

To replace the belt:

1. Use a belt with same section type or similar size. Do not sub-

stitute a “FHP” type belt. When installing the new belt, do not

use a tool (screwdriver or pry-bar) to force the belt over the

pulley flanges, this will stress the belt and cause a reduction

in belt life.

2. Loosen the motor mounting plate front bolts and rear bolts.

3. Push the motor and its mounting plate towards the blower

housing as close as possible to reduce the center distance

between fan shaft and motor shaft.

4. Remove the belt by gently lifting the old belt over one of the

pulleys.

5. Install the new belt by gently sliding the belt over both pul-

leys and then sliding the motor and plate away from the fan

housing until proper tension is achieved.

6. Check the alignment of the pulleys, adjust if necessary.

7. Tighten all bolts.

8. Check the tension after a few hours of runtime and re-adjust

as required.

ADJUSTABLE-PITCH PULLEY ON MOTOR

The motor pulley is an adjustable-pitch type that allows a servicer

to implement changes in the fan wheel speed to match as-installed

ductwork systems. The pulley consists of a fixed flange side that

faces the motor (secured to the motor shaft) and a movable flange

side that can be rotated around the fixed flange side that increases

or reduces the pitch diameter of this driver pulley. (See Fig. 6.)

As the pitch diameter is changed by adjusting the position of the

movable flange, the centerline on this pulley shifts laterally (along

the motor shaft). This creates a requirement for a realignment of

the pulleys after any adjustment of the movable flange. Also reset

the belt tension after each realignment.

CAUTION

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or

death.

Before performing service or maintenance operations on the

fan system, shut off all unit power and lockout/tag-out the unit

disconnect switch. DO NOT reach into the fan section with

power still applied to unit.

DIVIDER

BAROMETRIC

RELIEF

CLEANABLE

ALUMINUM

FILTER

FILTER

HOOD

FILTER

CLIP

OUTSIDE

AIR

Loading...

Loading...