26

provides a visual display of operational or sequential problems

when the power supply is uninterrupted. When a break in power

occurs, the IGC will be reset (resulting in a loss of fault history)

and the indoor (evaporator) fan ON/OFF times will be reset. The

LED error code can be observed through the viewport. During ser-

vicing refer to the label on the control box cover or Table 8 for an

explanation of LED error code descriptions.

If lockout occurs, unit may be reset by interrupting power supply

to unit for at least 5 seconds.

* A 3 second pause exists between LED error code flashes. If more

than one error code exists, all applicable codes will be displayed in

numerical sequence.

† Indicates a code that is not an error. The unit will continue to operate

when this code is displayed.

Orifice Replacement

This unit uses orifice type LH32RFnnn (where nnn indicates ori-

fice reference size). When replacing unit orifices, order the neces-

sary parts via Carrier RCD. See Table 10 for available orifice siz-

es. See Tables 11 and 12 for orifice sizes for Natural Gas and LP

fuel usage at various elevations above sea level.

Check that each replacement orifice is tight at its threads into the

manifold pipe and that orifice projection does not exceed maxi-

mum value. See Fig. 35.

Minimum Heating Entering Air Temperature

When operating on first stage heating, the minimum temperature

of air entering the dimpled heat exchanger is 50°F (10°C) continu-

ous and 45°F (7°C) intermittent for standard heat exchangers and

40°F (4°C) continuous and 35°F (2°C) intermittent for stainless

steel heat exchangers. To operate at lower mixed-air temperatures,

a field-supplied outdoor-air thermostat must be used to initiate

both stages of heat when the temperature is below the minimum

required temperature to ensure full fire operation. Wire the out-

door-air thermostat OAT (see Fig. 39) (part no. HH22AG106) in

series with the second stage gas valve (See Fig. 41.) Set the out-

door-air thermostat at 35°F (2°C) for stainless steel heat exchang-

ers or 45°F (7°C) for standard heat exchangers. This temperature

setting will bring on the second stage of heat whenever the ambi-

ent temperature is below the thermostat setpoint. Indoor comfort

may be compromised when heating is initiated using low entering

air temperatures with insufficient heating temperature rise.

Fig. 39 — OAT Connections

Troubleshooting Heating System

Refer to Tables 13 and 14 for additional troubleshooting topics.

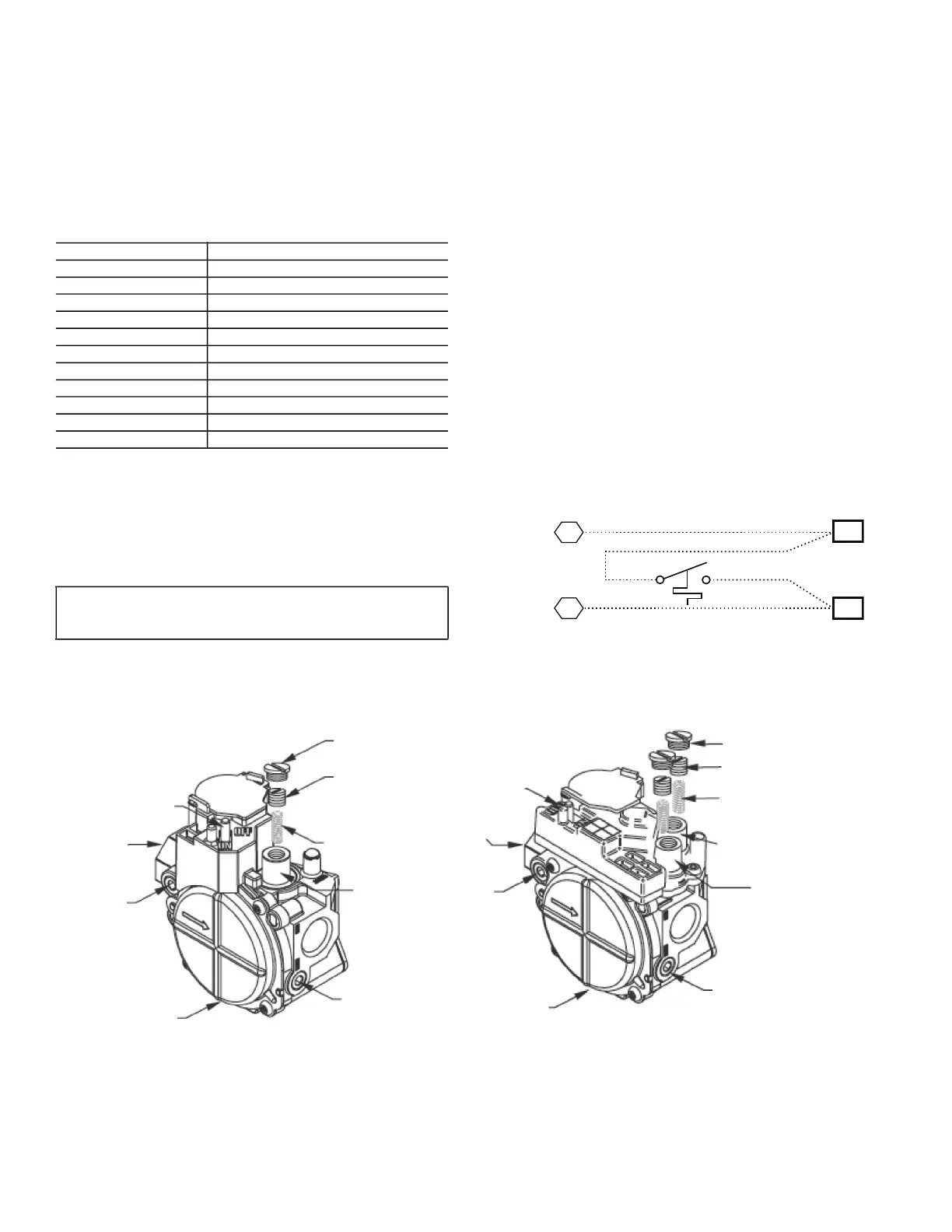

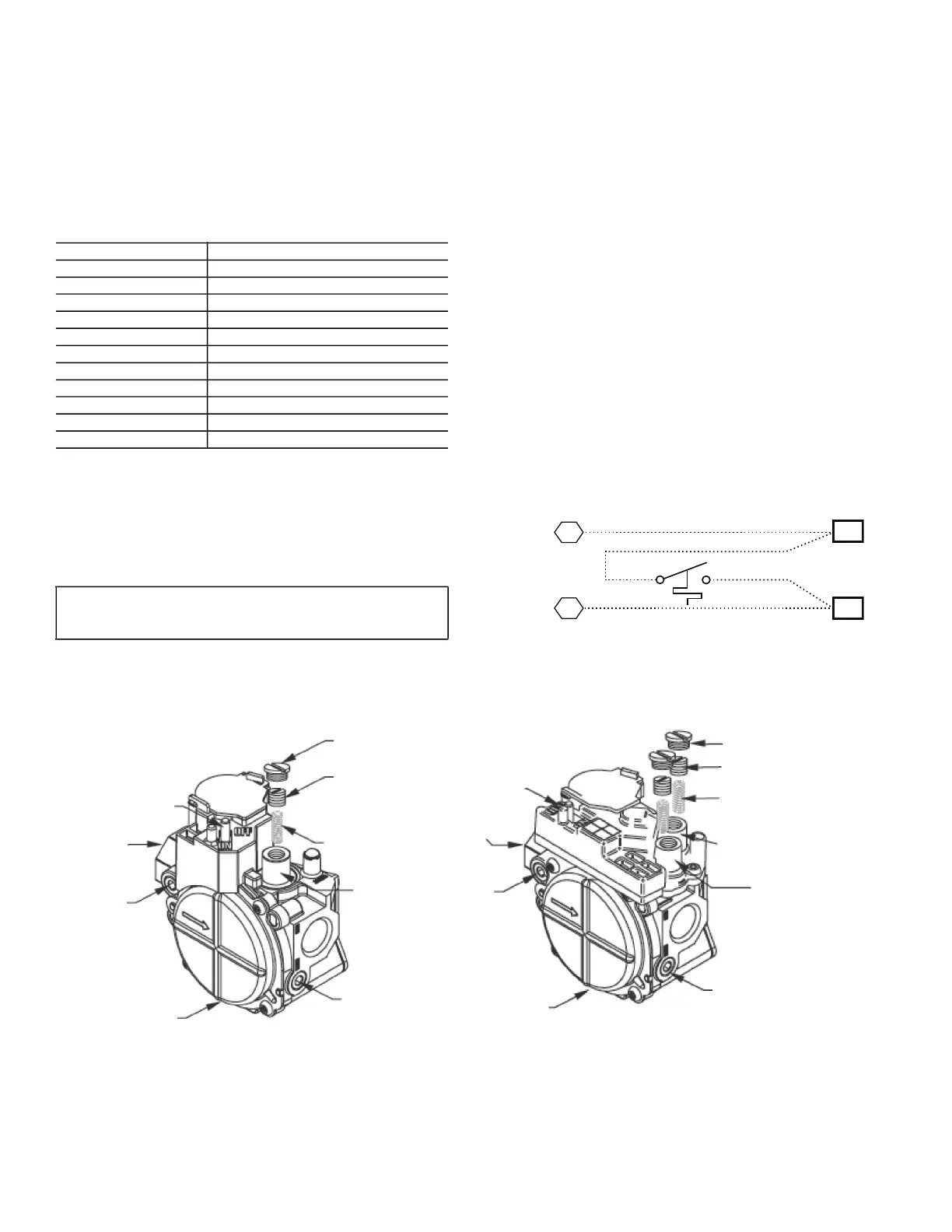

Fig. 40 — Gas Valves

Table 8 — LED Error Code Description

LED INDICATION ERROR CODE DESCRIPTION

On Normal Operation

Off Hardware Failure

1 Flash† Evaporator Fan On/Off Delay Modified

2 Flashes Limit Switch Fault

3 Flashes Flame Sense Fault

4 Flashes 4 Consecutive Limit Switch Faults

5 Flashes Ignition Lockout Fault

6 Flashes Induced-Draft Motor Fault

7 Flashes Rollout Switch Fault

8 Flashes Internal Control Fault

9 Flashes Software Lockout

LEGEND

LED — Light Emitting Diode

IMPORTANT: Refer to Troubleshooting Tables 13 and 14 for

additional information.

CTB

W2

Thermostat

TH1

TH2

W1

W1

W2

OAT

REGULATOR

COVER SCREW

PLASTIC ADJUST

SCREW

ON/OFF SWITCH

1/2" NPT INLET

INLET

PRESSURE

TAP

1/2" NPT OUTLET

MANIFOLD

PRESSURE TAP

GAS PRESSURE

REGULATOR

ADJUSTMENT

REGULATOR SPRING

(PROPANE - WHITE

NATURAL - SILVER)

ON/OFF SWITCH

1/2" NPT INLET

1/2" NPT OUTLET

INLET

PRESSURE

TAP

REGULATOR COVER SCREW

PLASTIC ADJUST SCREW

REGULATOR SPRING

(PROPANE - WHITE

NATURAL - SILVER)

MANIFOLD

PRESSURE TAP

LOW STAGE

GAS PRESSURE

REGULATOR ADJUSTMENT

SINGLE STAGE

2 STAGE

Loading...

Loading...