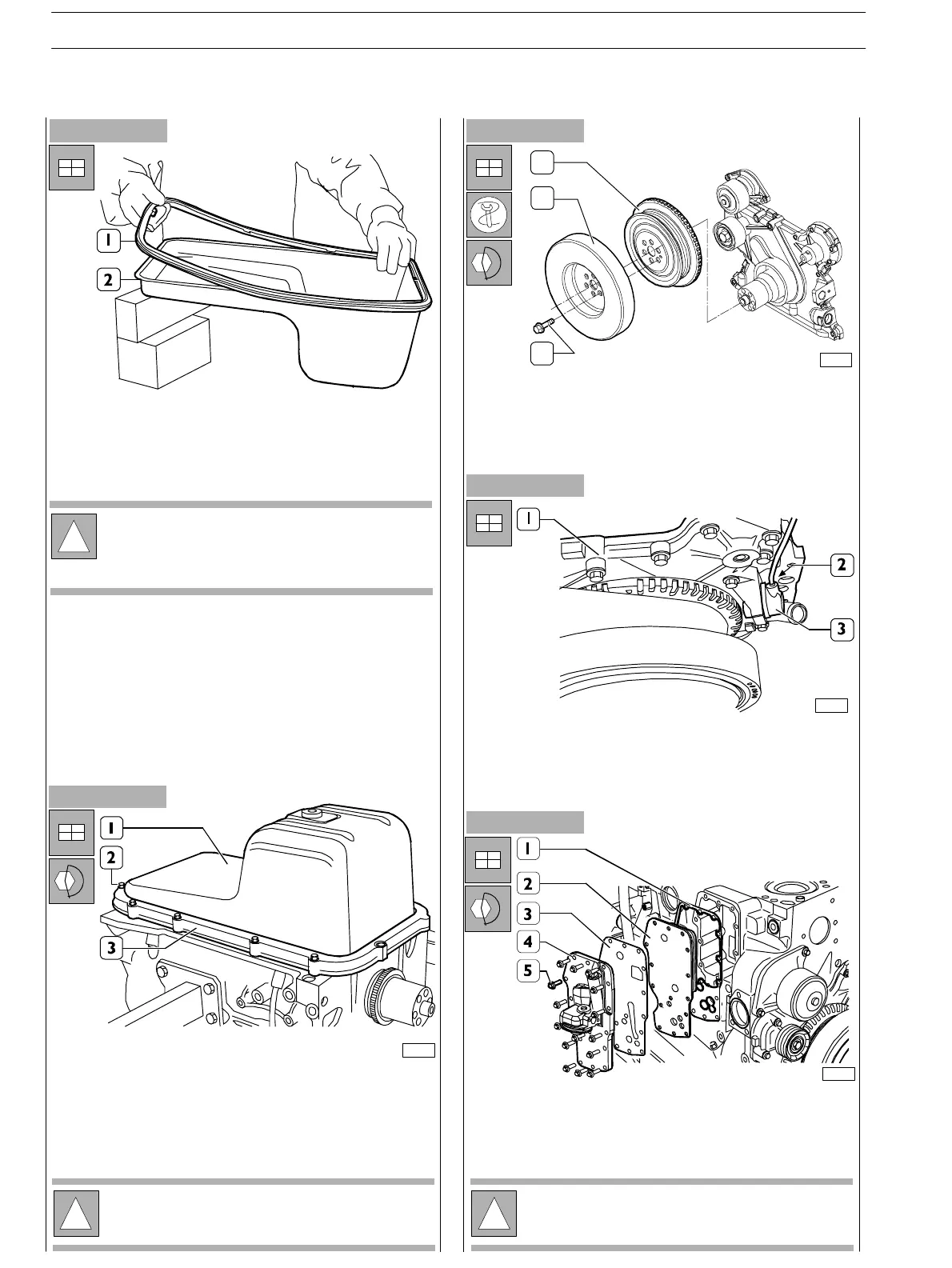

Figure 163

- Provide for new gasket replacement (1) of t he oil pan (2).

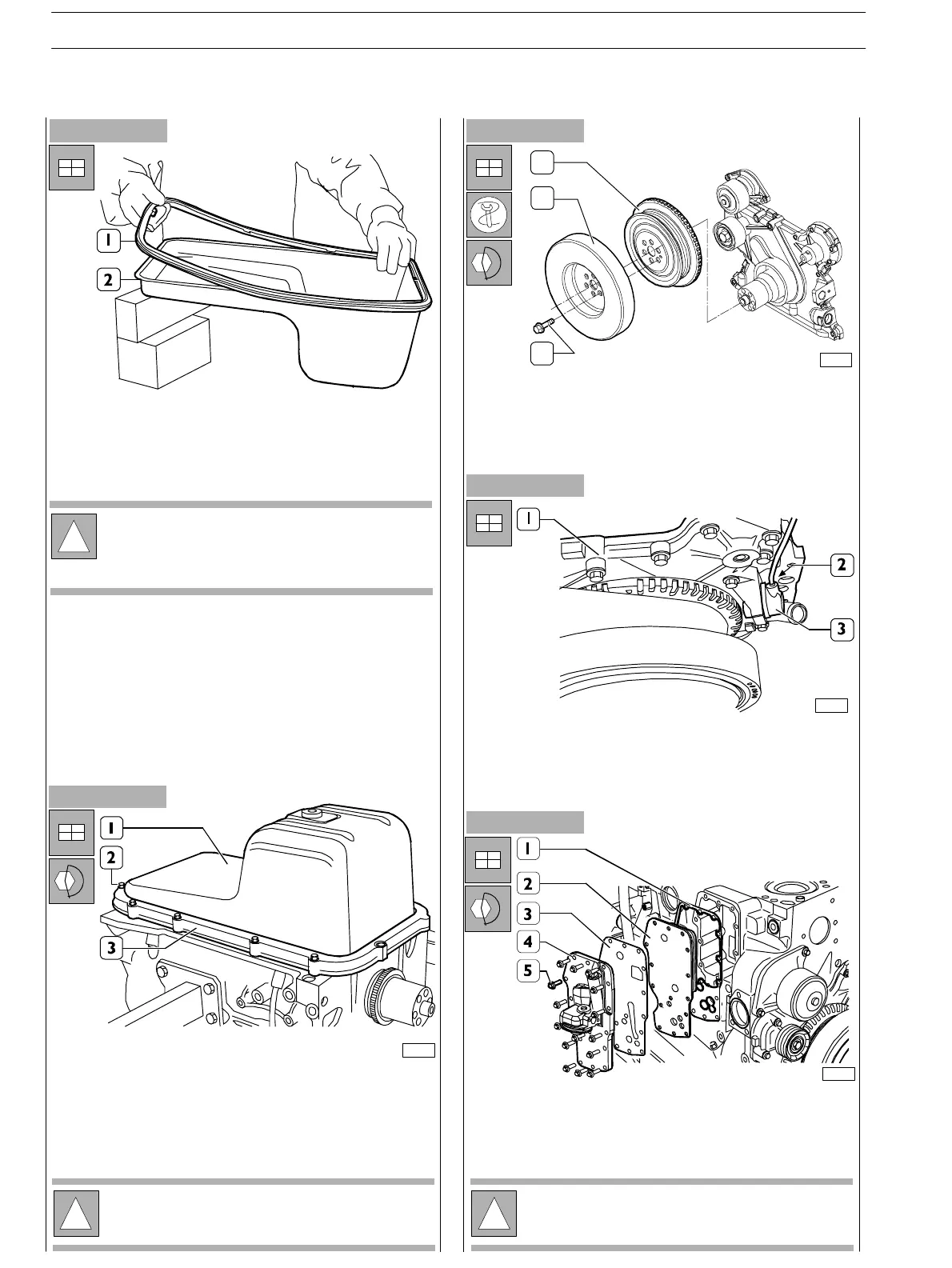

Figure 164

Figure 165

- Assemble the following elements to the block: new

gasket (1), heat exc hanger (2), new gasket (3), oil filter

bearing (4).

Tighten the screws (5) and lock them to the prescribed

couple.

- Assemble oil pan (1), apply the plate over it (2). Tighten

the screws (2) and lock them to the prescribed couple.

Figure 166

!

The pictures illustrating the pan and of the rose pipe

may not correspond to the ones of your model.

However the procedures described are applicable

anyway.

70154

!

Before assembly, always check that the threads of the

ports and of the screws have no evidence of tear and

wear nor dirt.

!

Before assembly, always check that the threads of the

ports and of the screws have no evidence of tear and

wear nor dirt.

1

2

3

74175

- Assemble the pulley (1) and the dumping flywheel (2) to

the driving shaft.

- Tighten the fixing screws (3) and clamp them to the

couple 68 ± 7 Nm.

70230

- Fit a new sealing rin g on t h e speed sensor (3) (if fitted).

- Fit the speed sensor (3) on the front c over (1) and

tighten the screw (2) to the specified torque (if fitted).

Figure 167

70231

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

54

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...