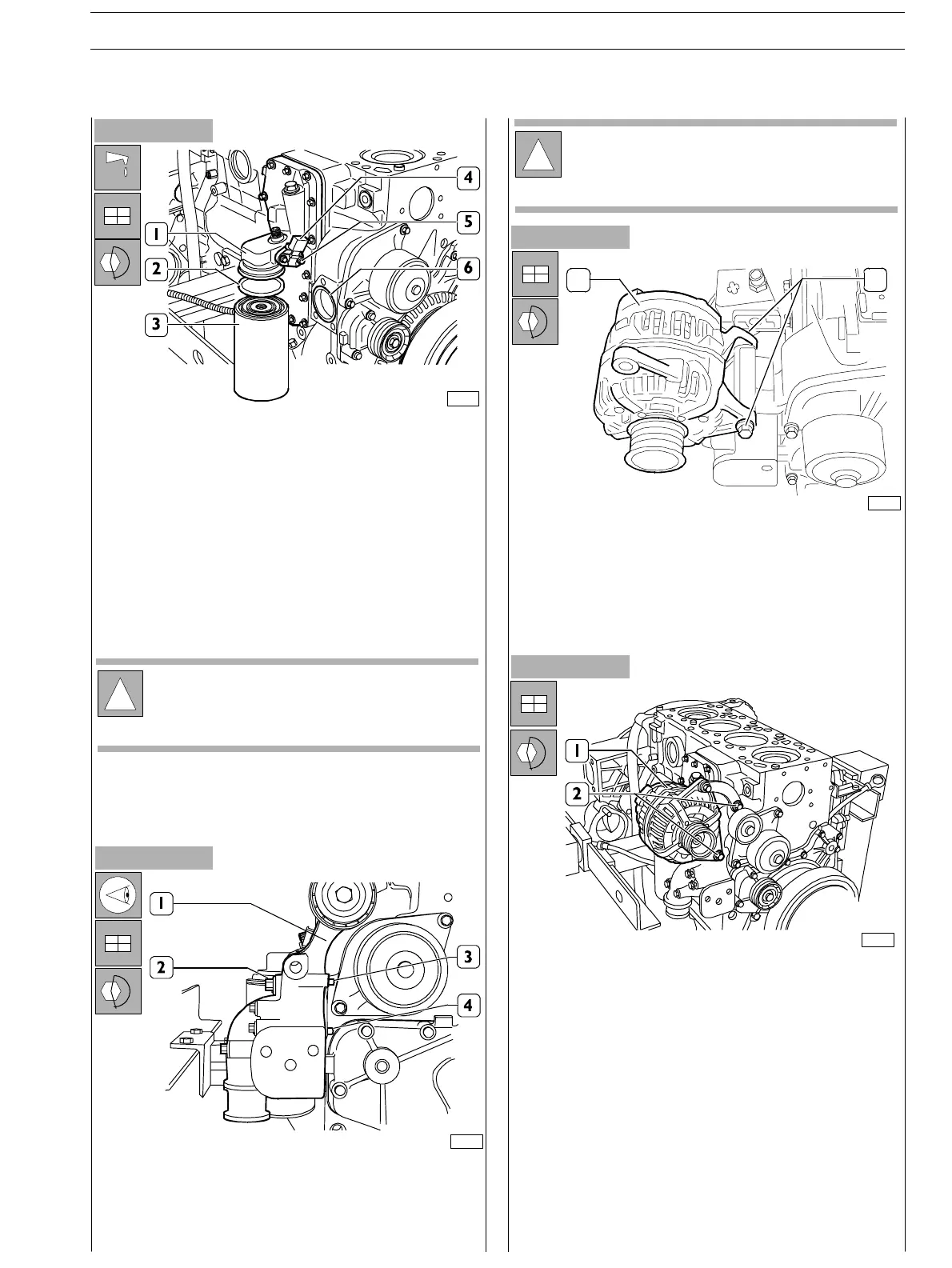

Figure 168

Figure 169

- Lubricate the fixing ring (2) using engine oil and place it

on the oil filter (3).

- Manually start the oil filter (3) on the bearing union (1)

until counter−boring, further screw up the oil filter (3)

by 3/4 turn.

- Apply, (if needed) new fixing ring on the oil

temperature/pressure sensor (4) and assemble it to the

bearing (1) tightening the fixing screws to t h e prescribed

couple.

- Tighten the screw (5) and lock it t o the prescribed

couple.

- Assemble the alternator bearing (1) ensuring that the

pins (3 and 4) are against the engine block.

- Tighten the screws (2) and lock them to the prescribed

couple.

Figure 170

- Place a new fixing ring on the block housing (6).

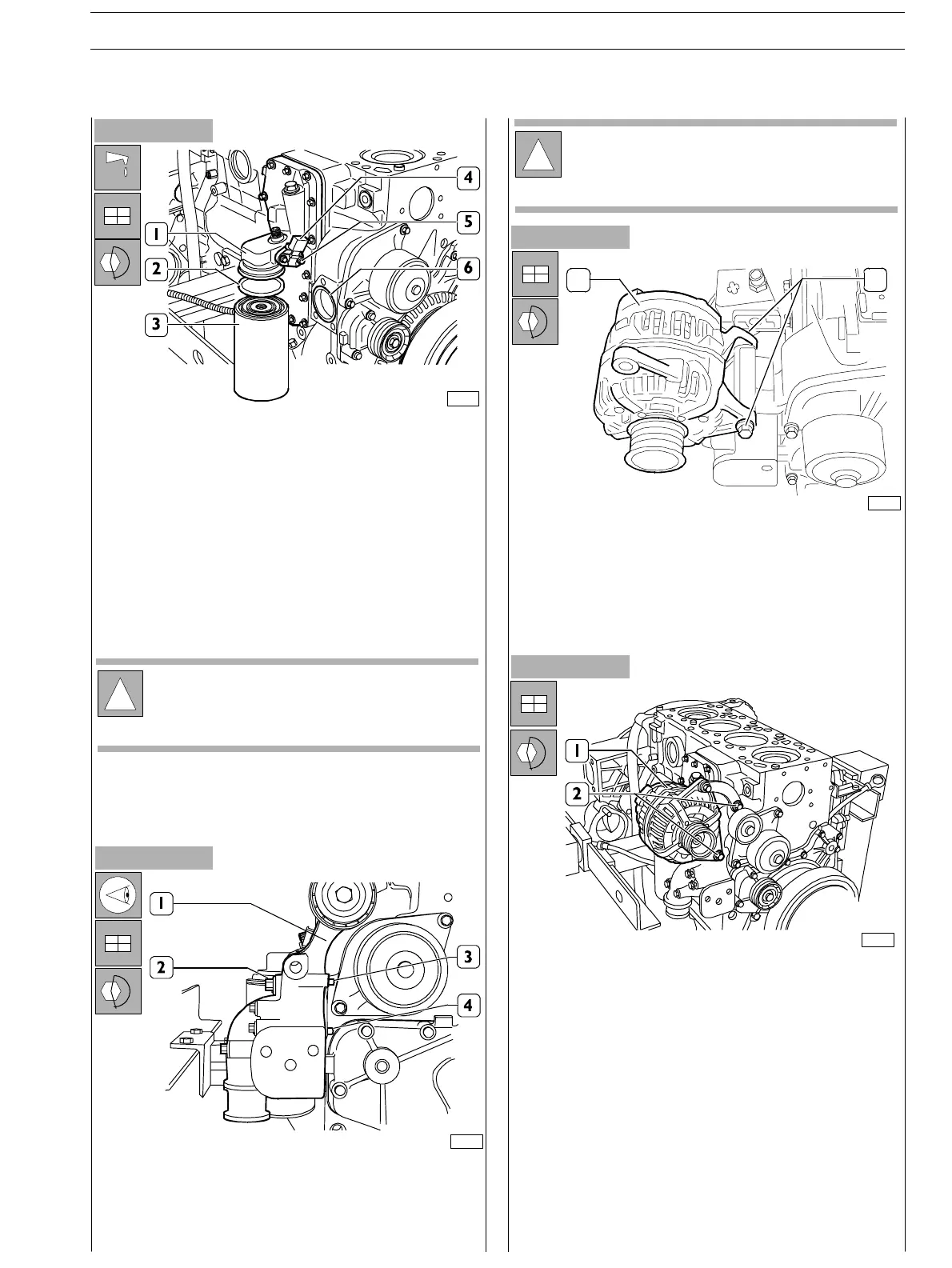

Figure 171

76113

!

In some applications, the bearing of the exchanger

shall be assembled to a screw threaded un ion

connected to the filter on the opposite side of the

engine, t hroughout two pipelines (see Figure 105).

70234

!

Before assembly, always check that the threads of the

ports and of the screws have no evidence of tear and

wear nor dirt.

12

75686

- Reassemble the alternator (1).

- Tighten the screw (2) and lock it t o the prescribed

couple.

74177

- Refit the alternator (1).

- Tighten the screw (2) to the specified torque.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

55

ED. FEBUARY 2003

zs

Loading...

Loading...