Figure 172

Figure 173

Figure 174

- Plac e the gasket (1) over the block.

The choice of the gasket’s thickness shall be made in

consideration of the cy lin der protrusion measured with

respect to the block’s upper surface.

Figure 175

76153

!

Verify that the engine block stand is clean.

Do no t grease the gasket. It is recommended to keep

the gasket inside packaging until assembly to the

cylinder head.

Gasket assembly shall be made following the

direction of wording printed on the gasket itself so

that this will be readable as indicated in the picture.

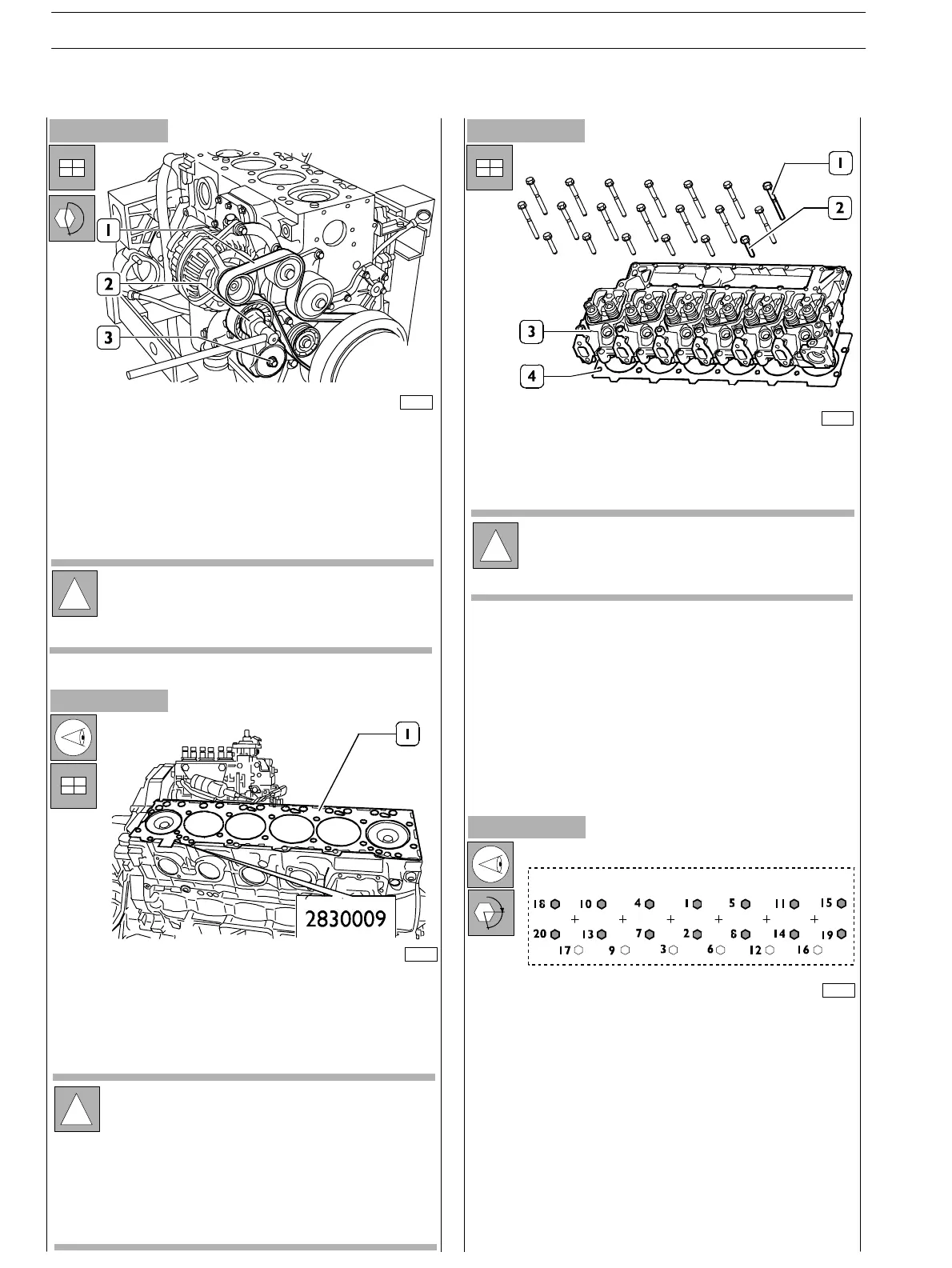

74178

- Refit the automatic belt tensioner (2).

- Tighten the screw (3) to the specified torque.

- Turn the automatic belt tensioner (2) to fit the belt (1)

on pulleys and guide rollers.

- Assemble alternator safety gu ard.

!

In case the same belt priory removed is assembled

again, proceed examining it carefully to check th ere

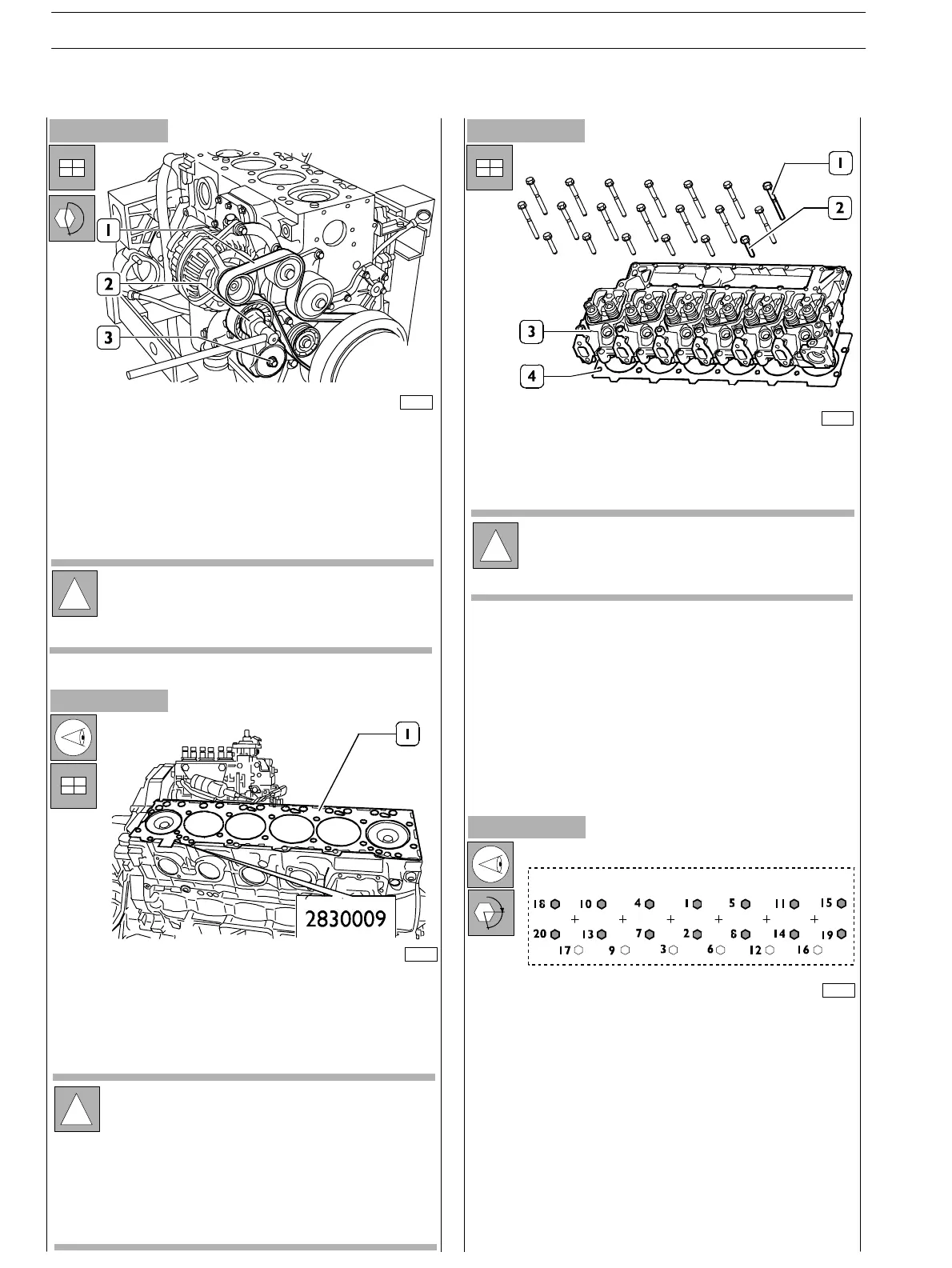

- Place the head (3) over the block and insert screws (1)

and (2).

76152

!

If the valves have been removed from the head, it is

necessary to assemble them before assembling the

head itself on the engine block.

α

76214

- Lubricate cylinder head bolts an d install to head.

- Bolts must be torqued using stitching pattern starting

with the c entre bolts and moving out. Bolts to be

torqued in stages: all bolts torqued to snug torque, then

90 degrees rotation for all bolts. Then a further 90

degrees for the M12 x 140 and M12 x 180.

M12 x 70 50 Nm + 90 deg’s

M12 x 140 40 Nm + 180 deg’s

M12 x 180 70 Nm + 180 deg’s

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

56

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...