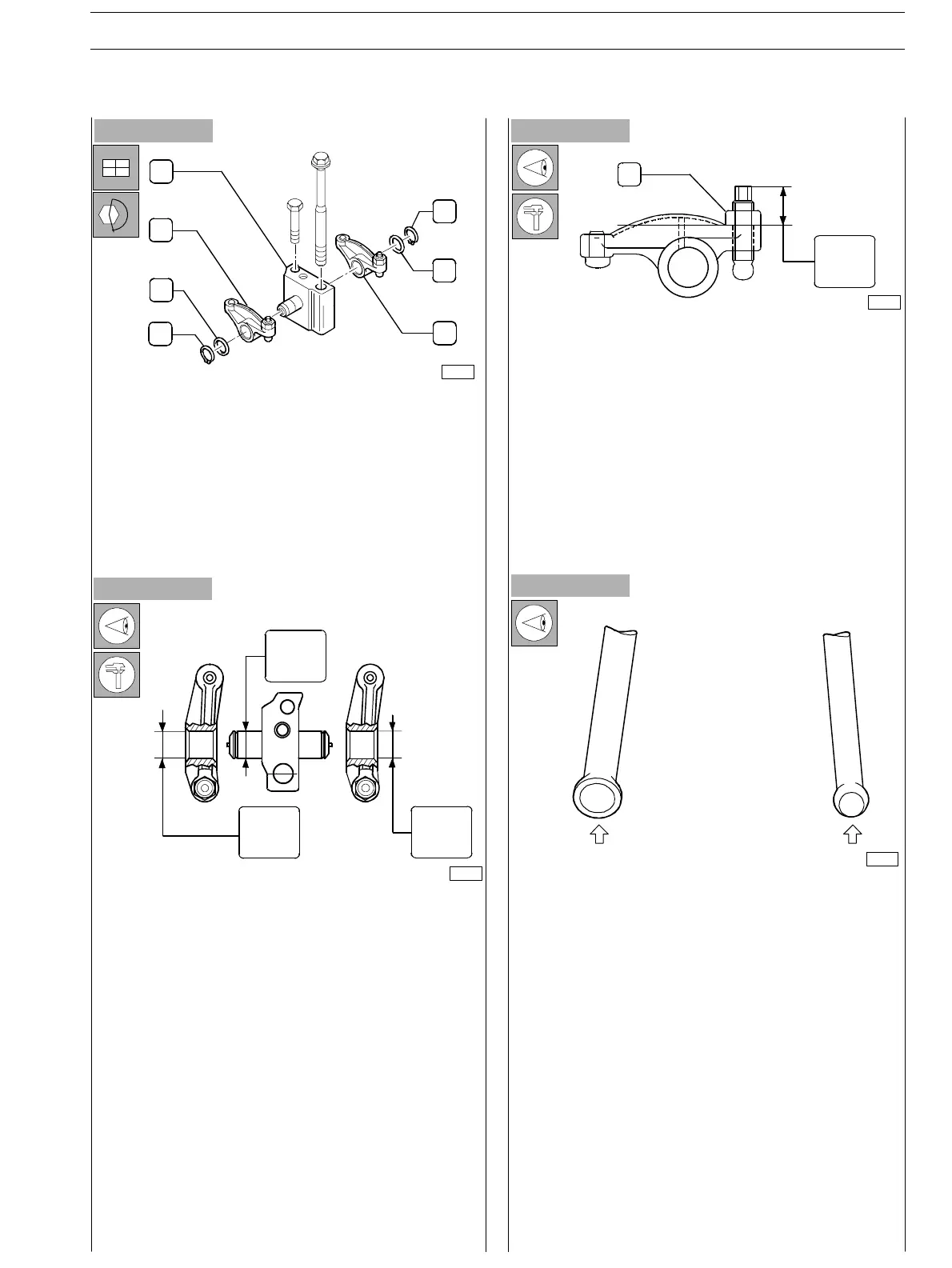

Figure 176

Figure 177

Figure 178

SHAFT AND ROCKER ARM BASIC DATA

Check the coupling surfaces of bearing and shaft: no evidence

of excessive wear shall be detected or damages.

Replace if necessary.

- Carry out the assembly of the rocker arms after previous

check of the components.

Figure 179

75705

1

2

3

4

1

2

3

ROCKER ARM UNIT COMPONENTS:

1. Elasti c ring − 2. Spacer− 3. Rocker arms−

4. Support.

75704

18.975

18.963

19.000

19.026

19.000

19.026

1

19.00

16.00

75702

ROCKER ARM ADJUSTMENT SCREW

If unscrewed, check adjustment quota.

Tighten the screw−threaded nut (1) to the i 0.25 − 0.75 Nm

couple.

32655

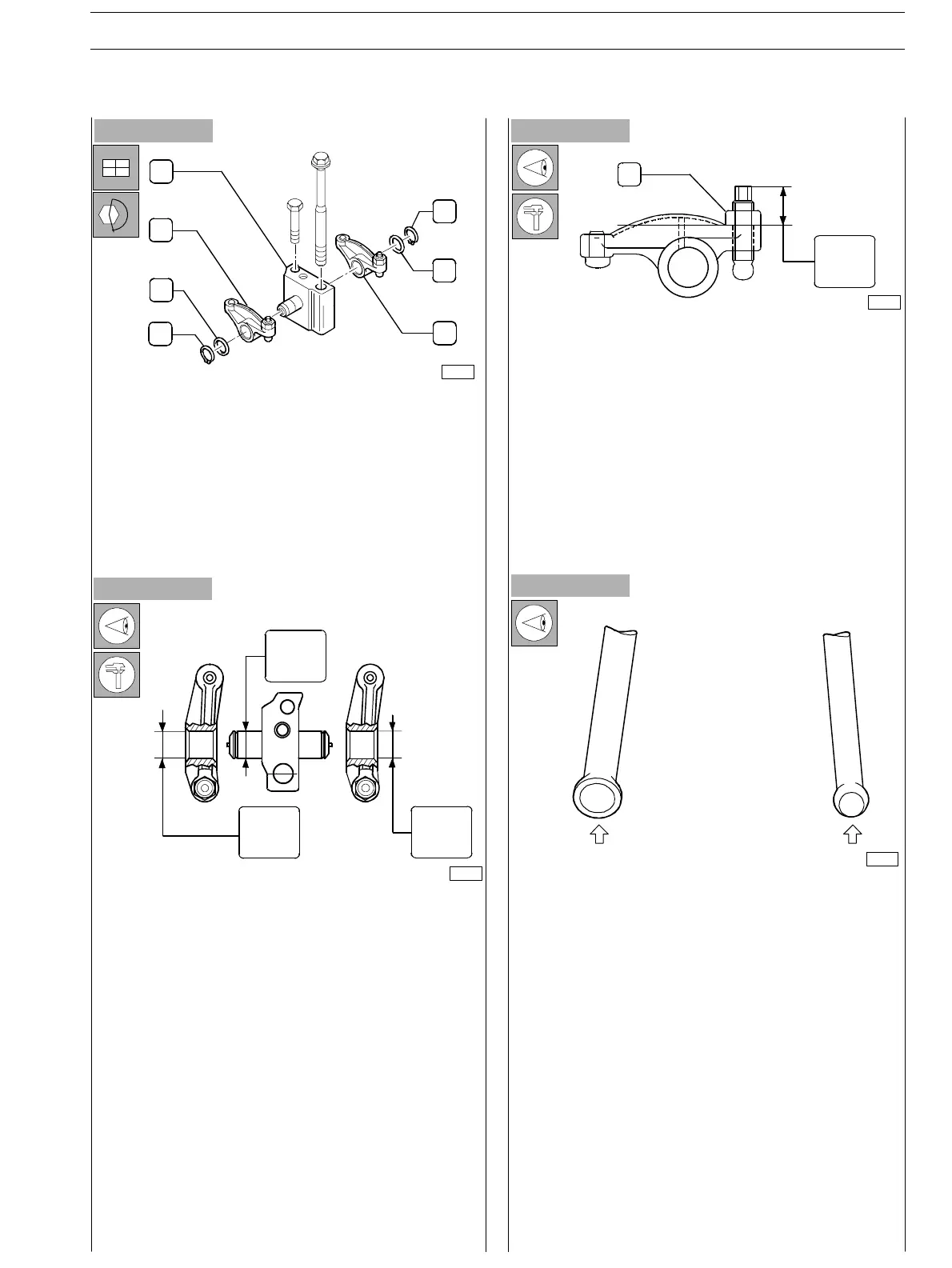

Before executing assembly, check the Rocker Arm driving

rods: these shall not be deformed; the spherical ends in

contact with the Rocker Arm adjustment screw and with the

tappet (arrows) shall not present evidence of seizure or

wear: in case of detection proceed replacing them.

The rods driving the suction and exhau st valves are identical

and therefore interchangeable.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

57

ED. FEBUARY 2003

zs

Loading...

Loading...