17

ATTENTION:

iThe correct

"lift"

type

arc strike is only obtained by pressing

the torch button after touching the piece

to be welded with the electrode befo-

rehand.

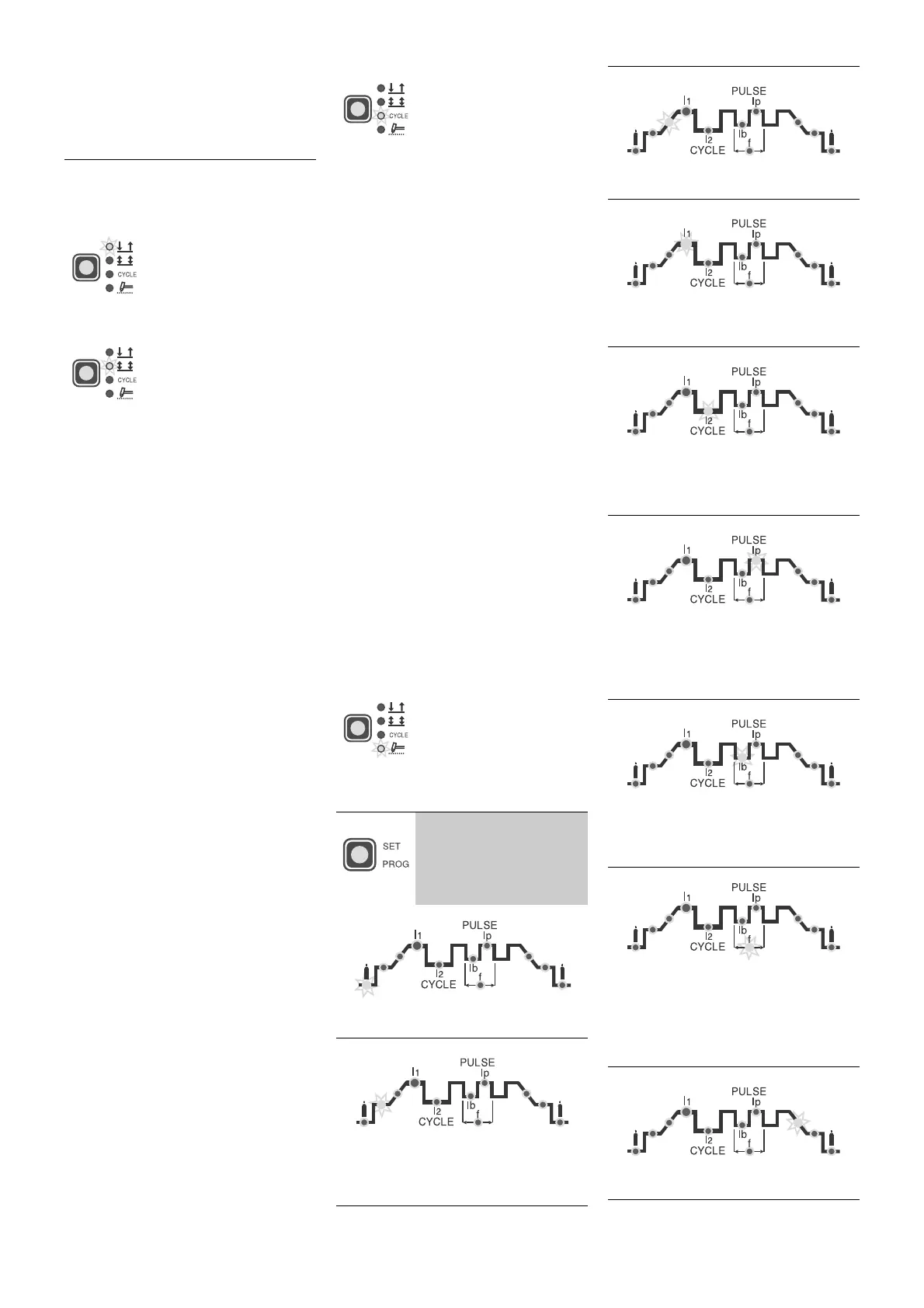

3)

Press the "weld mode" button and

set on one of the 4 options avail-

able:

•

2 STROKE

The TIG weld cycle is

done by pressing the

torch button, while weld-

ing will stop when you

release it.

•

4 STROKE

TIG welding is done as

follows:

A)

Pressing the torch

button strikes up the

arc and the current

stays at the INITIAL

value

B)

Peleasing the torch

button will start the

SLOPE UP (if pre-

sent) and the PRIN-

CIPAL CURRENT

will take itself to

value

I

1

C)

Pressing the torch

button will start the

SLOPE DOWN (if

present) and the cur-

rent will take itself to

the FINAL value

(crater current)

D)

Releasing the button

will finish the weld

cycle.

•

CYCLE

TIG welding is done as

follows with this function

on:

• pressing the torch but-

ton will strike up the

arc and the current

stays at the INITIAL

value

• releasing the torch

button will start the

SLOPE UP (if present)

and the current will

take itself to the PRIN-

CIPAL value (

I

1

)

• pressing and releasing

the torch button for

less than 1 second,

the weld current will

take itself to the DI

CYCLE (

I

2

) value; it

will be possible to

move an infinite num-

ber of times between

the two current levels

(

I

1

,

I

2

) by repeating this

operation

• pressing the torch but-

ton and keeping it

pressed down (for

more than 2 seconds)

will start the SLOPE

DOWN (if present)

and the current will

take itself to the FINAL

value (crater current)

• releasing the torch

button will finish the

weld cycle

•

SPOT-WELDING

Spot-welding can be

done for the set time (in

seconds) by pressing

the torch button after

which the arc will auto-

matically switch off

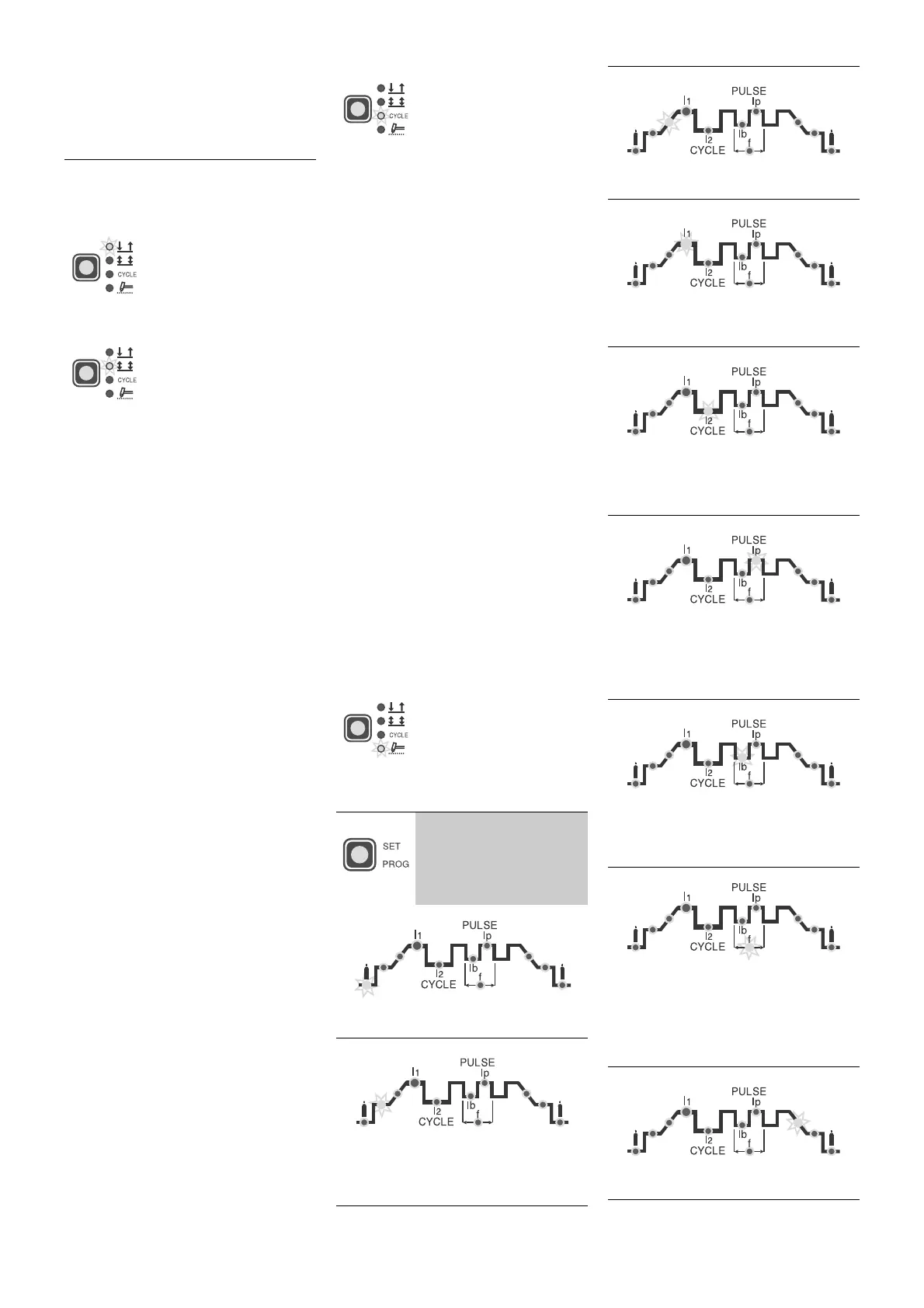

4)

The following weld

parameters can be set

by pressing the

SET/

PROG

button repeat-

edly

PRE-GAS time (0,05 ÷ 1 sec)

INITIAL weld CURRENT (5 ÷ 200A)

ATTENTION:

only programmable with

4 STROKE

or

CYCLE

functions on

SLOPE UP time (0 ÷ 5 sec)

PRINCIPAL weld CURRENT

I

1

(5 ÷ 200

A)

CYCLE CURRENT

I

2

(5 ÷ 200 A)

ATTENTION:

programmable only with

CYCLE

function on

PEAK CURRENT

I

p

(5 ÷ 200 A)

ATTENTION:

programmable only with

ON PULSE

or

EASY PULSE

functions

on

BASIC CURRENT

I

b

(5 ÷ 200 A)

ATTENTION:

only programmable with

ON PULSE

or

EASY PULSE

on

PULSATION FREQUENCY

f

(0,5 ÷ 500

Hz)

ATTENTION:

programmable only with

ON PULSE

or

EASY PULSE

functions

on

SLOPE-DOWN time (0 ÷ 8 sec)

Loading...

Loading...