19

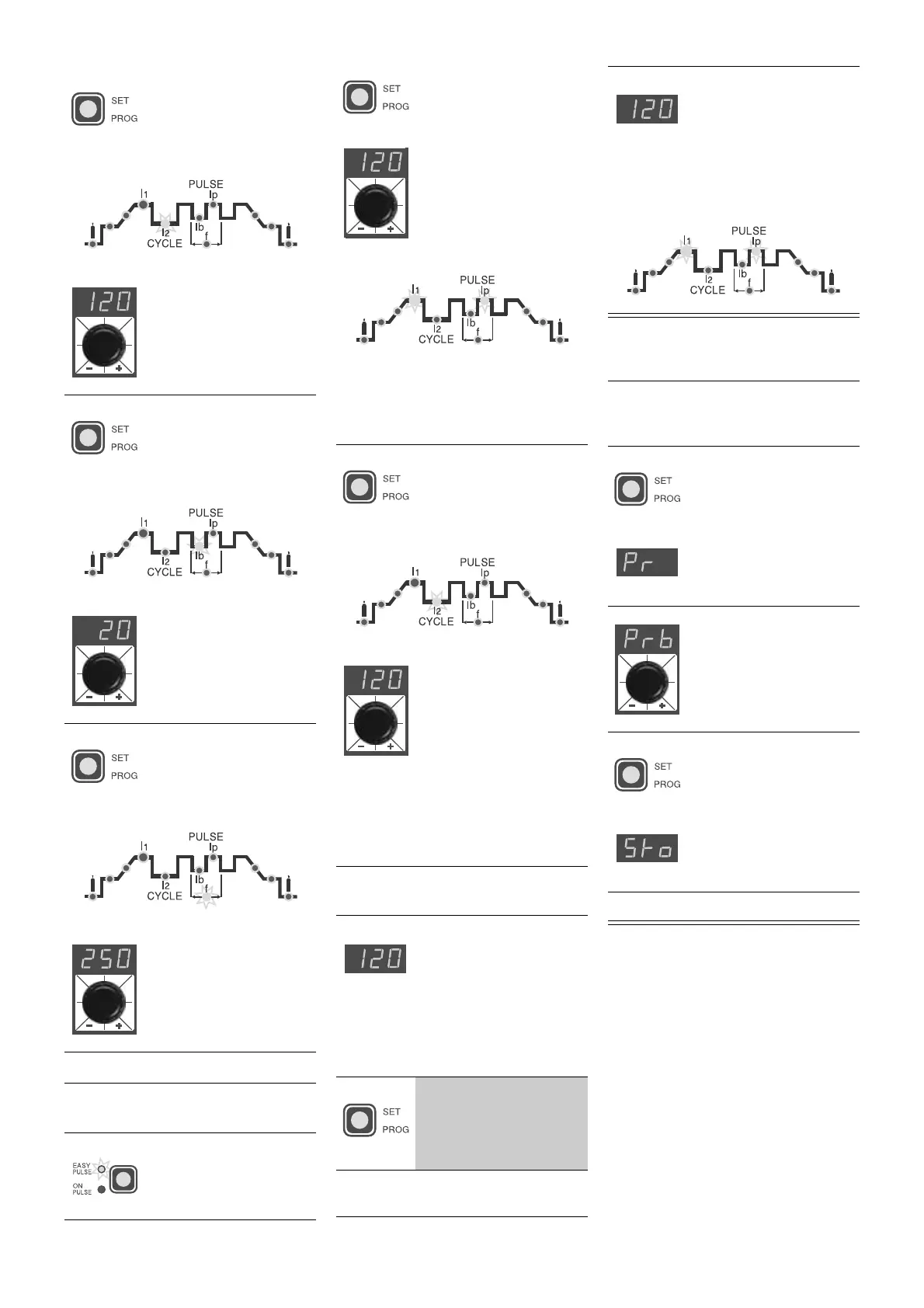

EASY PULSE METHOD

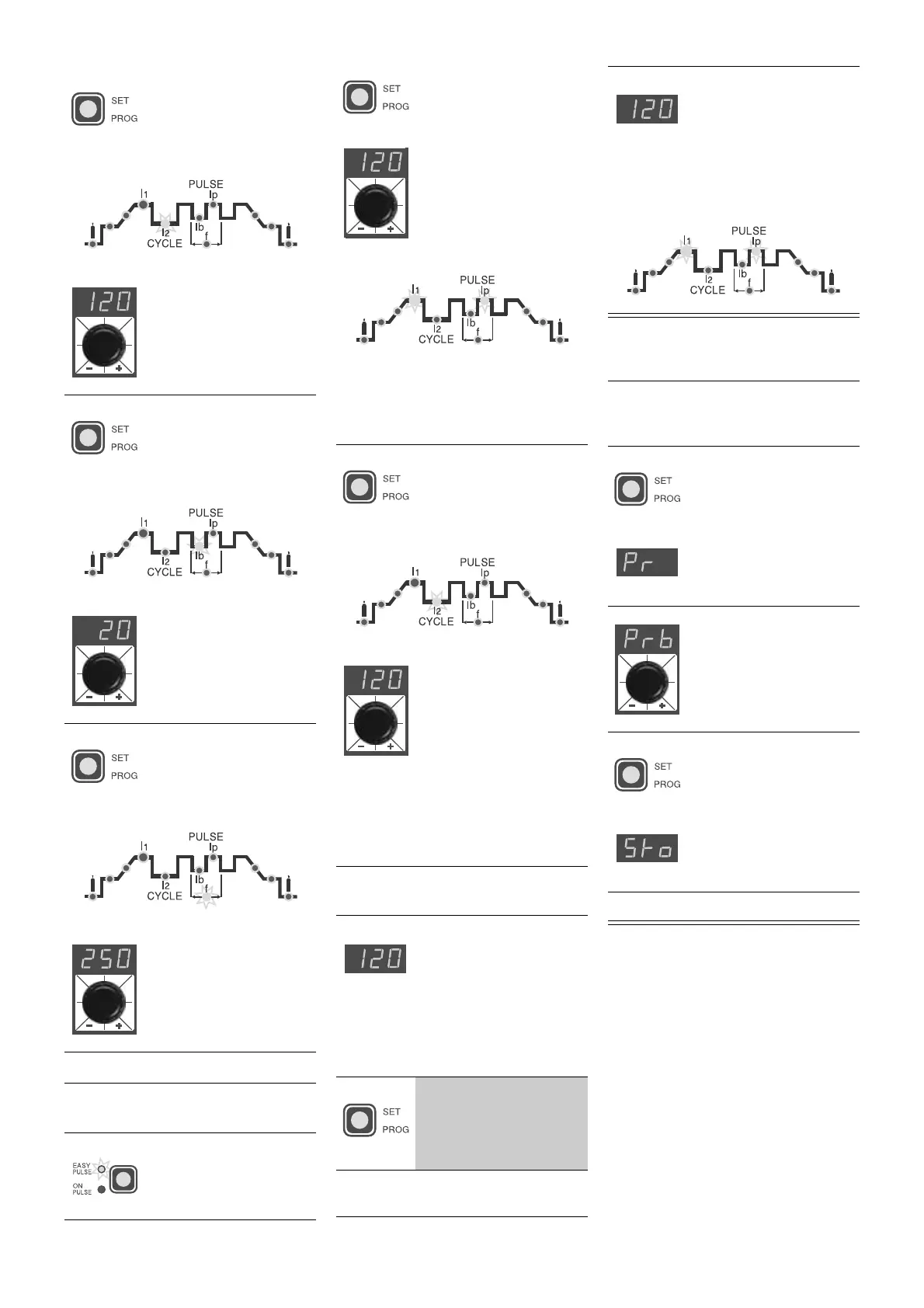

INPUT STORAGE

PROGRAMMED WELDING

Once the programme has been memo-

rized the operator can only weld with the

pre-set values and cannot change any

of the parameters. Go to

MANUAL

welding to make any changes.

5A)

Press the

SET/PROG

key until the RED led of

the 2nd level of PEAK

CURRENT

I

2p

(5 ÷ 200

A) starts flashing

• Adjust the parameter by

turning the special dial

6A)

Press the

SET/PROG

key until the RED led of

the 1st level BASIC

CURRENT (5 ÷ 100 A)

starts flashing

• Adjust the parameter by

turning the special dial

7A)

Press the

SET/PROG

key until the RED led of

the PULSATION FRE-

QUENCY (0.5 ÷ 500

Hz) starts flashing

• Adjust the parameter by

turning the special dial

ATTENTION:

go on to point

8)

3B)

Press the "pulsation"

button until the

EASY

PULSE

function is

working

4B)

Press the

SET/PROG

key until the GREEN

led

I

1

and the RED led

I

p

will start flashing;

adjust the 1

st

level

PEAK CURRENT

I

1p

(5

÷ 200 A); value by tur-

ning the special dial.

ATTENTION:

with

EASY PULSE

working and adjusting the value of the

1st level PEAK CURRENT (

I

1p

) you will

have the values of the other 1st level

parameters (

I

1b

,

f

) in synergy

5B)

Press the

SET/PROG

key until the RED led of

the 2nd level PEAK

CURRENT

I

2p

(5 ¸ 200

A) starts flashing

• Adjust the parameter by

turning the special dial

ATTENTION:

adjusting the value of the

2nd level PEAK CURRENT (

I

2p

) while

EASY PULSE

is working, you will have

the values of the other 2nd level para-

meters (

I

2b

,

f

) in synergy

8)

If you want a test weld,

the led of the selected

parameter will flash

and the value of the

parameter being set

will be visualized on

the display while this is

being done

9)

Keep pressing the

SET/PROG

key for

more than 1 second to

leave the weld parame-

ter setting phase

10)

Use the

CYCLE

function for

PUL-

SATING TIG

welding

NOTE:

The RED LED

I

p

and the GREEN LED

I

1

remain on continuously

during the welding process

and the current value

being used for welding will

be visualized on the

display

ATTENTION:

The GREEN LED

I

1

must

be on continuously to enter the input

storage phase

1)

Keep pressing the

SET/PROG

key (for

about 3 seconds) until

the letters

Pr

appear

on the display

2)

Turn the dial to select

the number of the pro-

gramme where input

must be stored

3)

Keep pressing the

SET/PROG

key until

the letters

Sto

appear

on the display

4)

Input has been stored

Loading...

Loading...