8

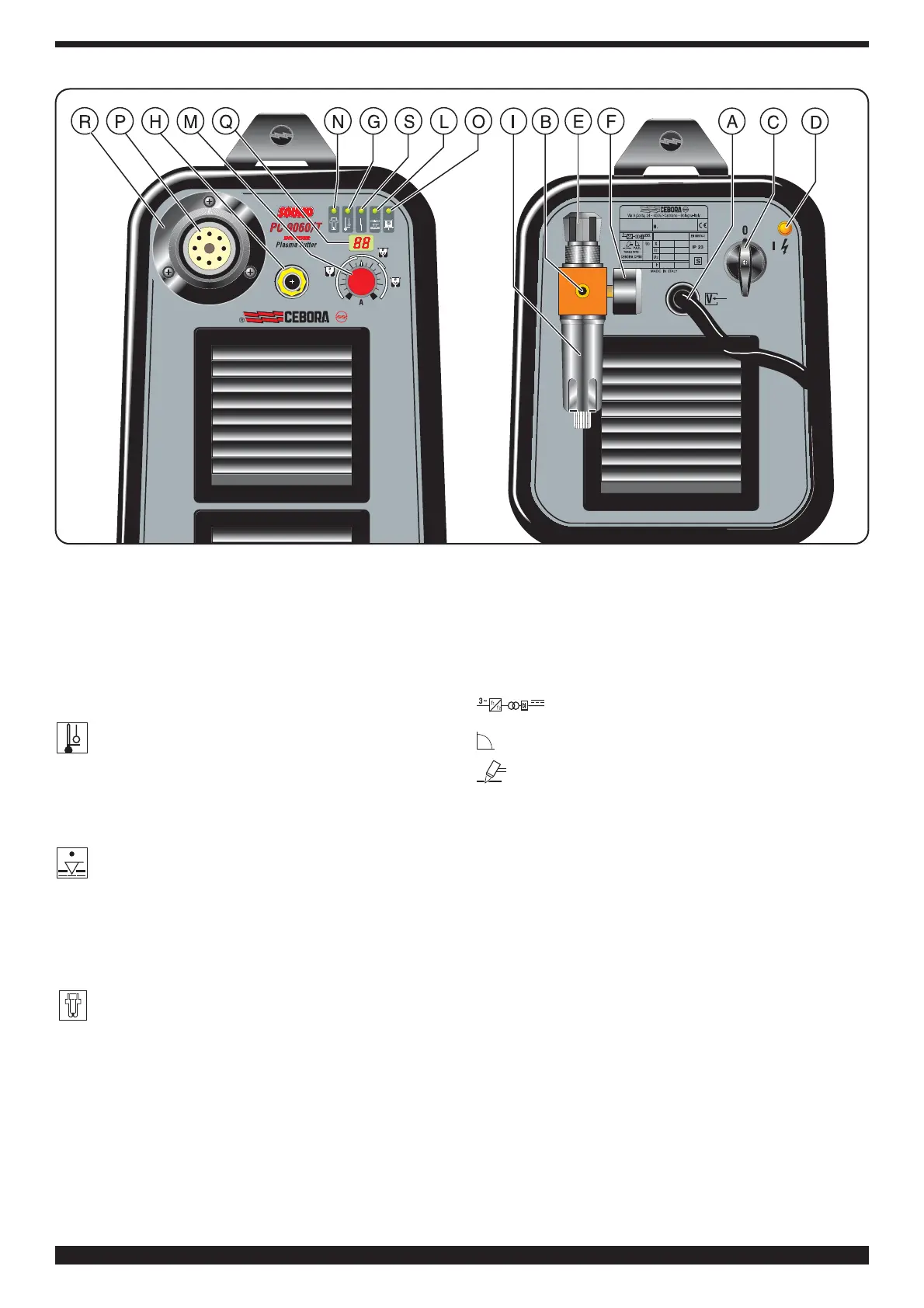

R) Safety guard

S) Blocked LED; lights when hazardous conditions

arise.

2.3 SAFETY DEVICES

This system comes equipped with the following safety

devices:

Overload cutout:

1) To avoid overloads during the pilot arc ignition and

during the cut. It is evidenced by the G led continu-

osly on (see fig.1).

2) Stop that the machine working at a room temperature

lower than -20°C. It is evidenced by the blinking G led

(see fig.1).

Pneumatic:

Located on the torch inlet to prevent low air pres-

sure. The LED L lights when tripped (see fig.1).

The blinking L led means that the pressure has temporar-

ily gone below 3.2 ÷ 3.5 bar.

Electrical:

1) Located on the torch body, to prevent hazardous volt-

ages from occurring on the torch when, swirl ring, elec-

trode or nozzle holder are replaced;

2) Blocks the equipment when the electrode is worn

to the point where it needs to be replaced. This

function is indicated when the LED N lights (fig.1). If this

safety device is tripped, shut off the machine before

replacing the electrode and nozzle. (Art. 356 only).

• Do not remove or short-circuit the safety devices.

• Use only original spare parts.

• Always replace any damaged parts of the machine

with original materials.

• Do not run the machine without its housings. This

would be dangerous to the operator and anyone else

in the work area, and would prevent the machine from

being cooled properly.

2.4 EXPLANATION OF TECHNICAL SPECIFICATIONS

EN60974.1 The machine has been built according to

EN 50199-92 this European standards.

N°..................... Serial number.

Always indicate this for any request regar

ding the machine.

....... Three-phase static frequency converter -

transformer/rectifier.

................... Drooping characteristic.

.................Suitable for plasma cutting.

TORCH TYPE........Type of torch that may be used with this

machine.

U

0

. PEAK........Secondary open-circuit voltage. Peak

value.

X....................... Percentage duty cycle.

The duty cycle expresses the percentage

of 10 minutes for which the machine may

work at a certain current I

2

and voltage

U

2

without overheating.

I

2

....................... Cutting current.

U

2

..................... Secondary voltage at cutting current I

2

.

On art. 354, this voltage is measured by

cutting with the nozzle in contact with

the workpiece, and on art. 356 by cutting

with the nozzle 3 mm away from the work

piece.

If this distance increases, the cutting

voltage also increases and the duty

cycle X% may drop.

U

1

......................Rated supply voltage

3~ 50/60Hz....... Three-phase 50-or 60-Hz power supply

I

1

....................... at the corresponding

cutting current I

2

and voltage U

2

.

IP23.................. Housing protection rating.

Fig.1

Loading...

Loading...