ENGLISH

55

Transport and

longer periods out of service/storage

• CEDIMA

®

• Technical Documentation • All rights reserved as per ISO 16016 • Subject to modications due to progressive development •

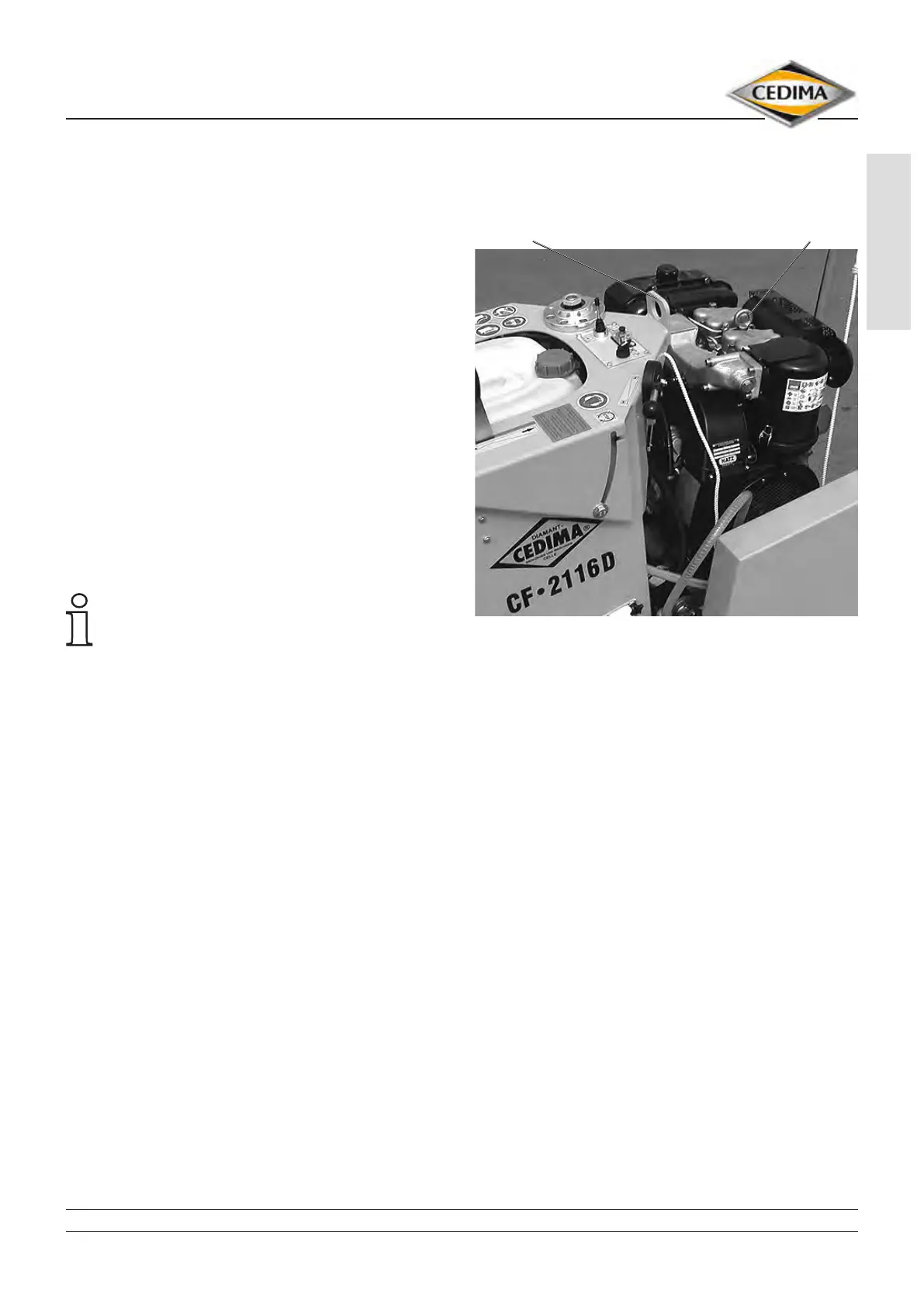

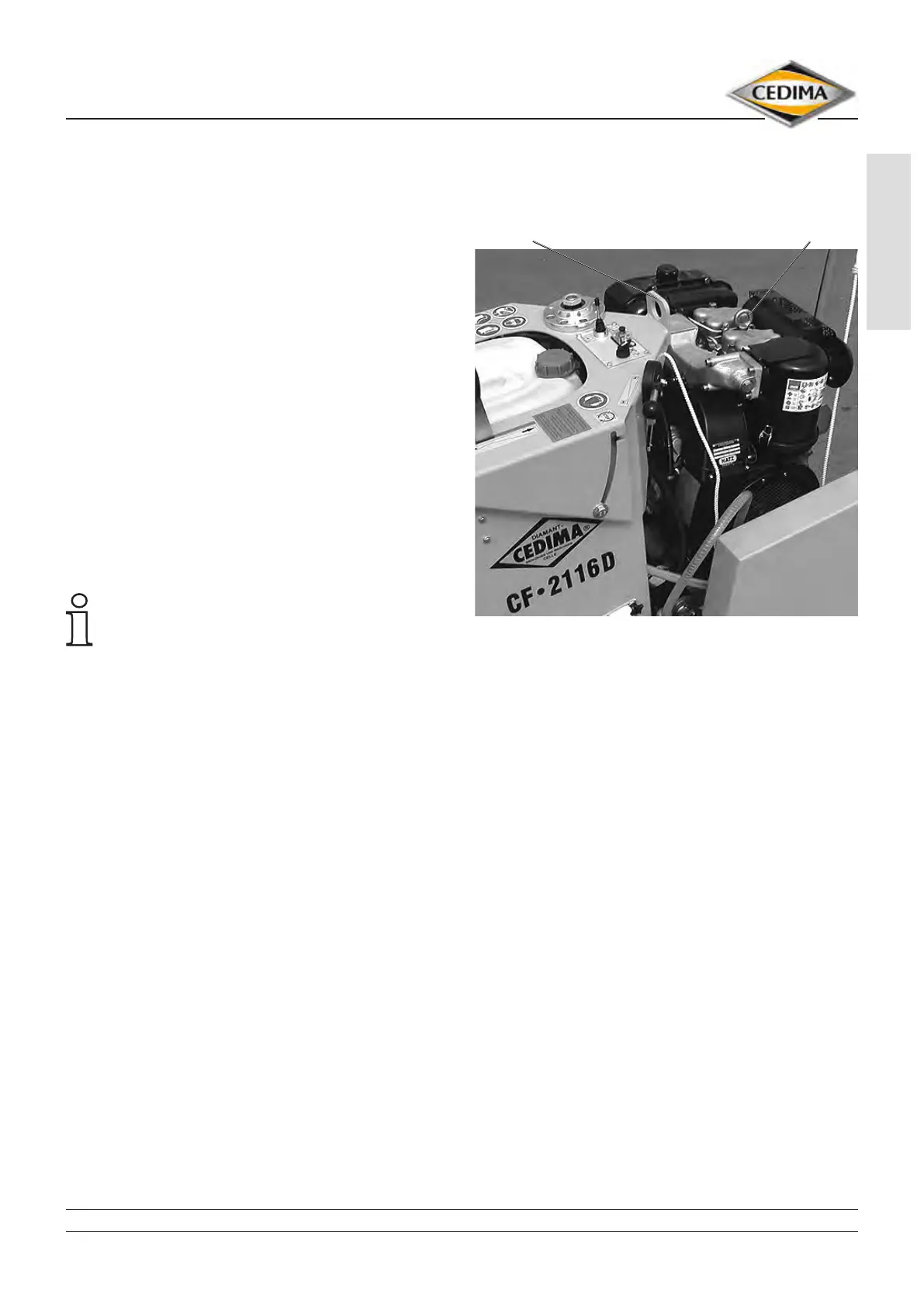

For transporting the joint cutter CF-2116 D observe the

following points:

• Only transport the joint cutter with ther the (blade)

drive motor stopped.

• Dismount the diamond saw blade.

• Lower the cutting shaft (without saw blade).

• Disconnect the external water supply hose.

• Only transport the joint cutter standing on its wheels,

horizontally, in order to prevent leakage of uids (mo-

tor, compact hydraulic unit, hydrostatic feed drive,

fuel tank, battery, …).

• Engage the (switched off) feed drive. Thus the brakes

for the rear drive wheels are applied.

• For transport by crane there is a ring eye (g. 7.1) at

the joint cutter (superstructure box, control panel,

front). Using this ring eye the machine will hang

almost horizontally.

Do not lift the joint cutter by means of the ring eye

on the motor!

The motor ring eye (g. 7.1) is only meant for mounting/

dismounting the motor.

• Lift the front pointer, sway in the rear pointer, push in

the two push rods (section 3.2.6) and dismount the

attaching tube from the hydraulic hand pump (sec-

tion 3.9.4). This will reduce the transport volume and

prevent damages (for example bending).

• In order to reduce the transport length farther the

front blade guard (hood) can be opened.

• After the transport check that all screws and compo-

nents are well tightened.

CF-2116 D, ring eye(s) for transport by crane Fig. 7.1

joint cutter ring eye motor ring eye

Observe the following in case of longer periods out of

service/storage:

• Observe the service intervals (table 6.5).

• Observe the motor operating manual.

• Observe the battery documentation.

• Drain completely the joint cutter’s cooling/rinsing

system.

• Check oil levels of motor, hydrostatic feed gear and

hydraulic quick-lifting. If necessary, ll up.

• Release tension of V-belts.

• Clean, grease and renew corrosion protection of all

moving parts.

• Release the wheels (prevention of footprints) by

underlaying wood of suitable thickness.

• Store the joint cutter at a dry and dust-free place,

protected from extreme sunlight and vibrations.

7.0 Transport and longer periods out of service/storage of the CF-2116 D

Loading...

Loading...