Support before removing the MFC.

- Prior to replacing an MFC thoroughly purge the system or replace/re-clean contaminated

components.

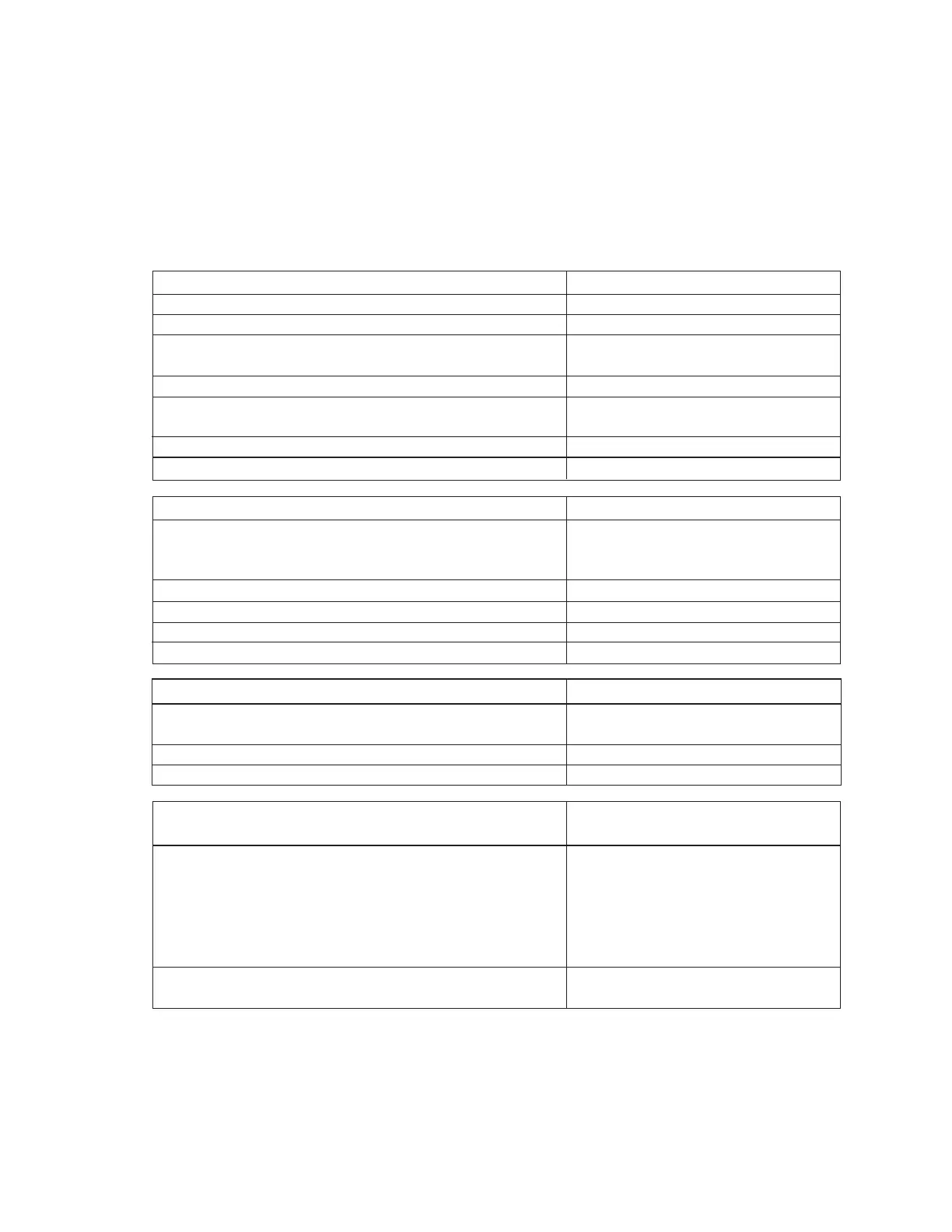

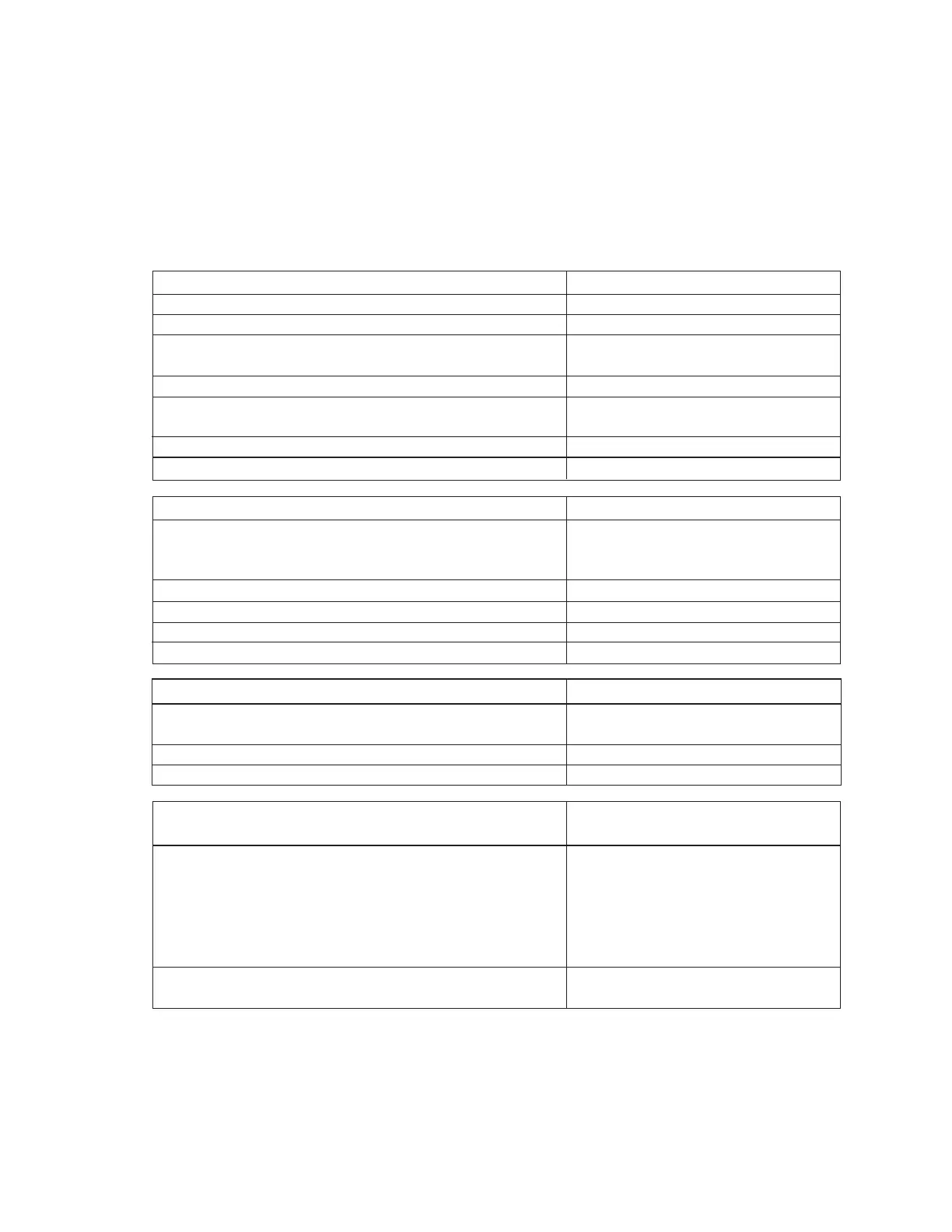

NO GAS FLOW WHAT TO DO?

Is the gas supply turned on?

Check the shut-off valve and the pressure readout.

Is the regulator on and at the correct operating pressure? Typically 25 psia.

Are any upstream or downstream isolation valves closed, either by the system Verify that the pneumatic valves are operating.

or because of failure?

Is the MOD LED on the MFC lit solid green? Look at the top of the unit.

Is the NET LED on the MFC lit solid green? Look at the top of the unit.

If not, cycle power to the unit or re-boot.

Is the commanded setpoint from the system “0%”? Use the tool software. Verify interlocks.

Has the MFC been commanded off by an active “valve close” input? Use the tool software. Verify interlocks.

FLOW OUT-OF-RANGE WHAT TO DO?

Is the gas inlet/outlet pressure differential either too high or too low? Verify that the pressure is correct for this gas and

•

If the differential is too high, MFC valve voltage or drive will be zero or range, typically 25 psia.

abnormally low for the setpoint.

Is the MOD LED on the MFC lit solid green?

Look at the top of the unit.

Is the setpoint correct for the required flow? Use the tool software to verify this.

Is the MFC calibrated for the particular gas? Check the MFC label. Run Flow Verify.

Is the MFC zero correct? (If not refer to the Zeroing Procedure.) Verify Leak Check Rates are OK.

NO GAS CONTROL; FLOW IS AT OR ABOVE MAXIMUM WHAT TO DO?

Is there too much gas pressure across the MFC? Verify that the pressure is correct for this gas and

range, typically 25 psia.

Is a system “valve open” or “purge” input activated? Use the tool software to verify this.

Is the setpoint correct for the required flow? Use the tool software to verify this.

FLOW UNABLE TO REACH A SETPOINT (When the setpoint is raised WHAT TO DO?

beyond this point, the MFC remains at some value lower than the setpoint.)

Is the gas inlet/outlet pressure-differential sufficient? Verify that the pressure is correct for this gas and

•

If the differential is too low, the MFC valve voltage or drive will be at its range, typically 25 psia.

maximum value when the setpoint is raised above the point where the flow

will increase.

•

Adjust regulator to the proper operating pressure. Verify that the pressure is

correct for this gas and range, typically 25 psia.

Is the MFC calibrated for the gas flowing? Check the MFC label. Run Flow Verify.

•

If not, replace the MFC with properly calibrated unit.

, Inc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...