4-4

Visual and contact pressure checks

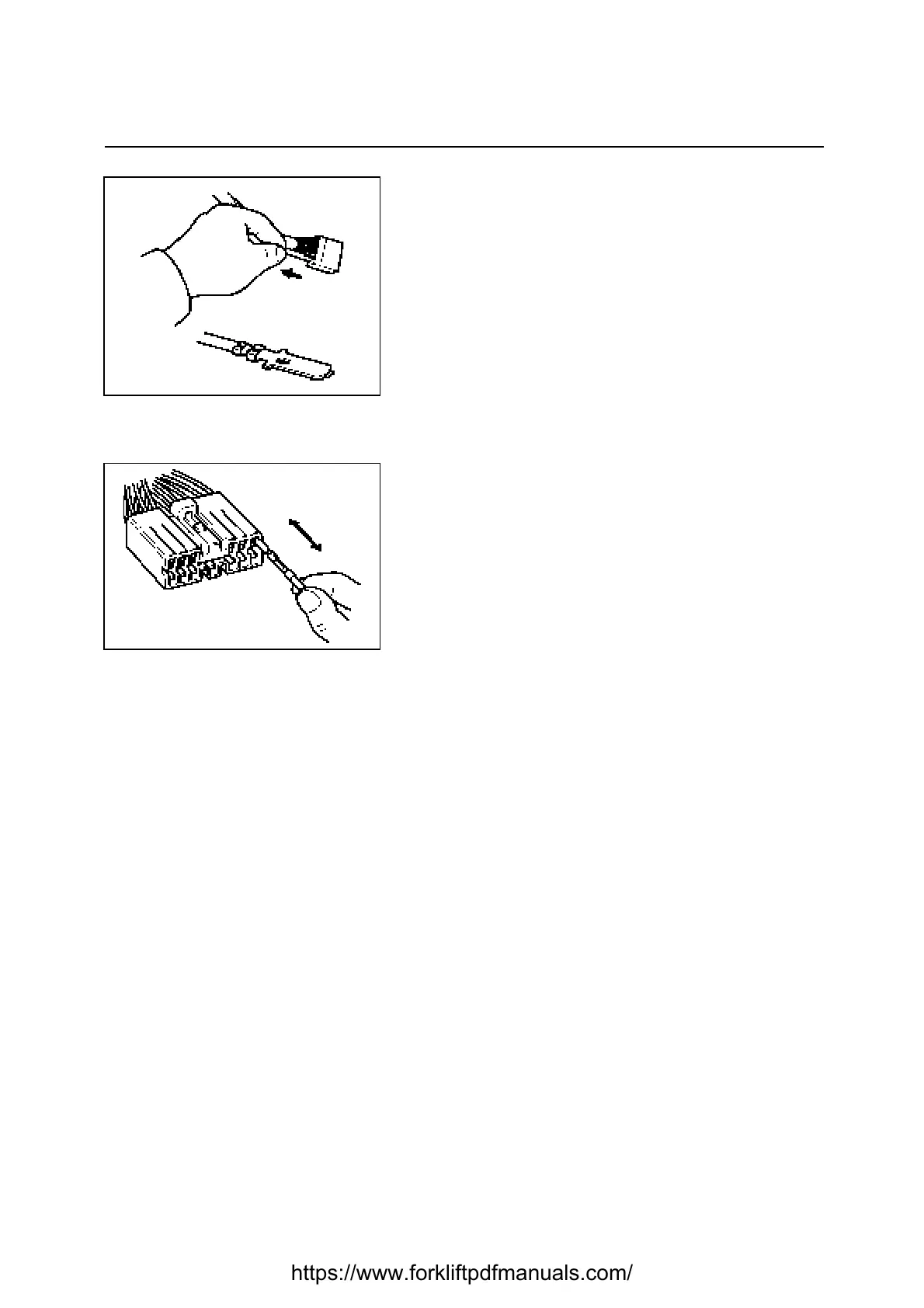

• Disconnect the connectors at both ends of the

corresponding harnesses

• Visually inspect that there is neither rust nor foreign matter

trapped at connector terminals

• Inspect that there is no loosening or damage at the locked

portion. Also, lightly pull the wire harness from the

connector to check that it does not come off

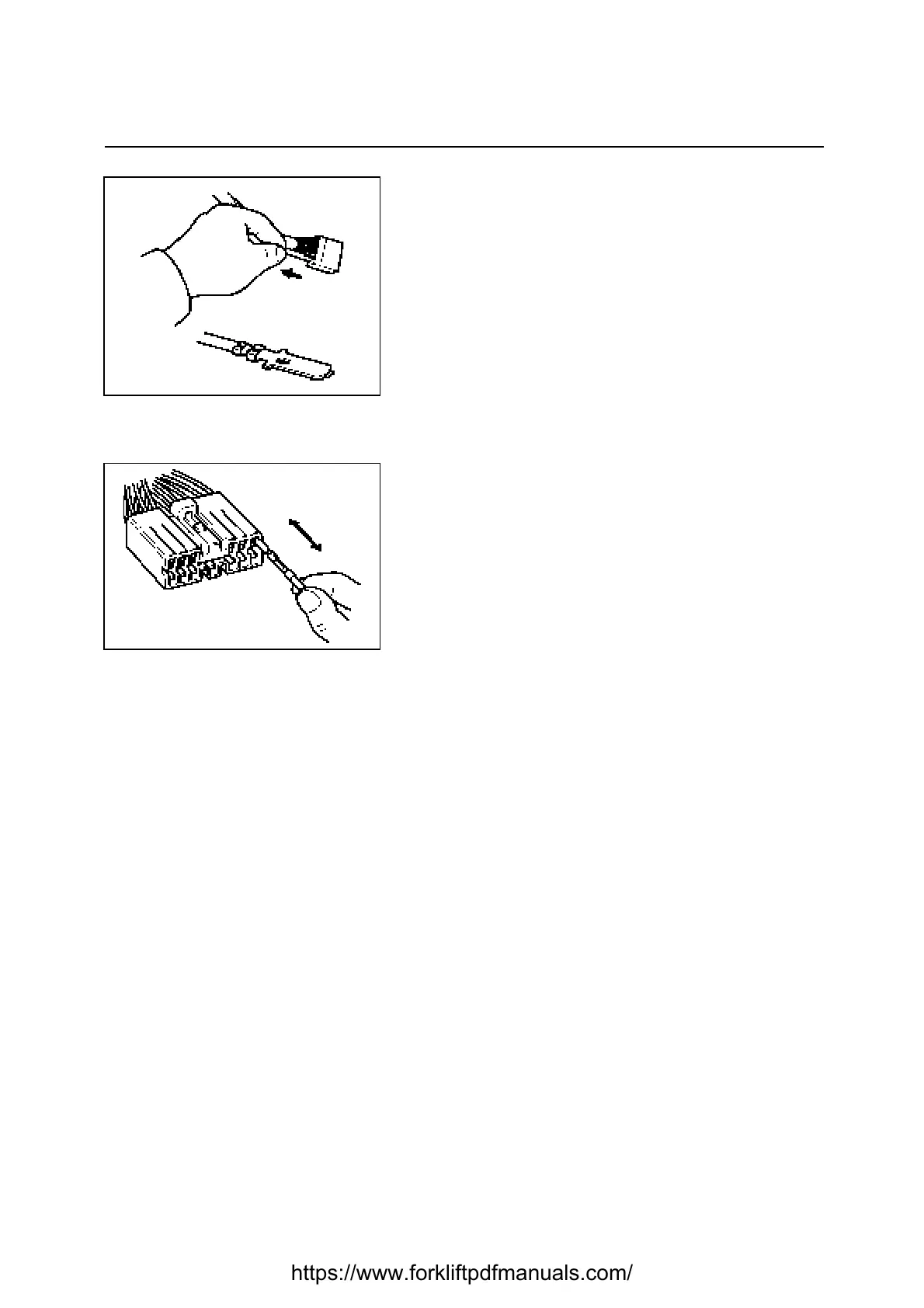

• Insert a male terminal the same as that of the terminal to

check into a female connector and check the force of

extraction.

Defective contact may exist at a terminal where the

extracting force is less than that of other terminals

Remarks:

Notes:Even if there is rust or foreign matter trapped at

the terminal, or the contact pressure between male and

female terminals is low, abnormal contact condition may

be changed to normal by disconnecting and

reconnecting the connector. In that case, repeat

connector connection and disconnection several times.

If defect is perceived even once, terminal contact may be

defective.

The above information, concerning the inspection of the connectors, are referred to specific type as shown

in the drawing. The same procedure must be apply for all types of machine connectors.

https://www.forkliftpdfmanuals.com/

Loading...

Loading...