8-5

2

2

2

3

2

2

2

8

8

9

10

11

12

13

14

15

16

17

18

18

18

18

18

18

Point Operations

[Point 1]

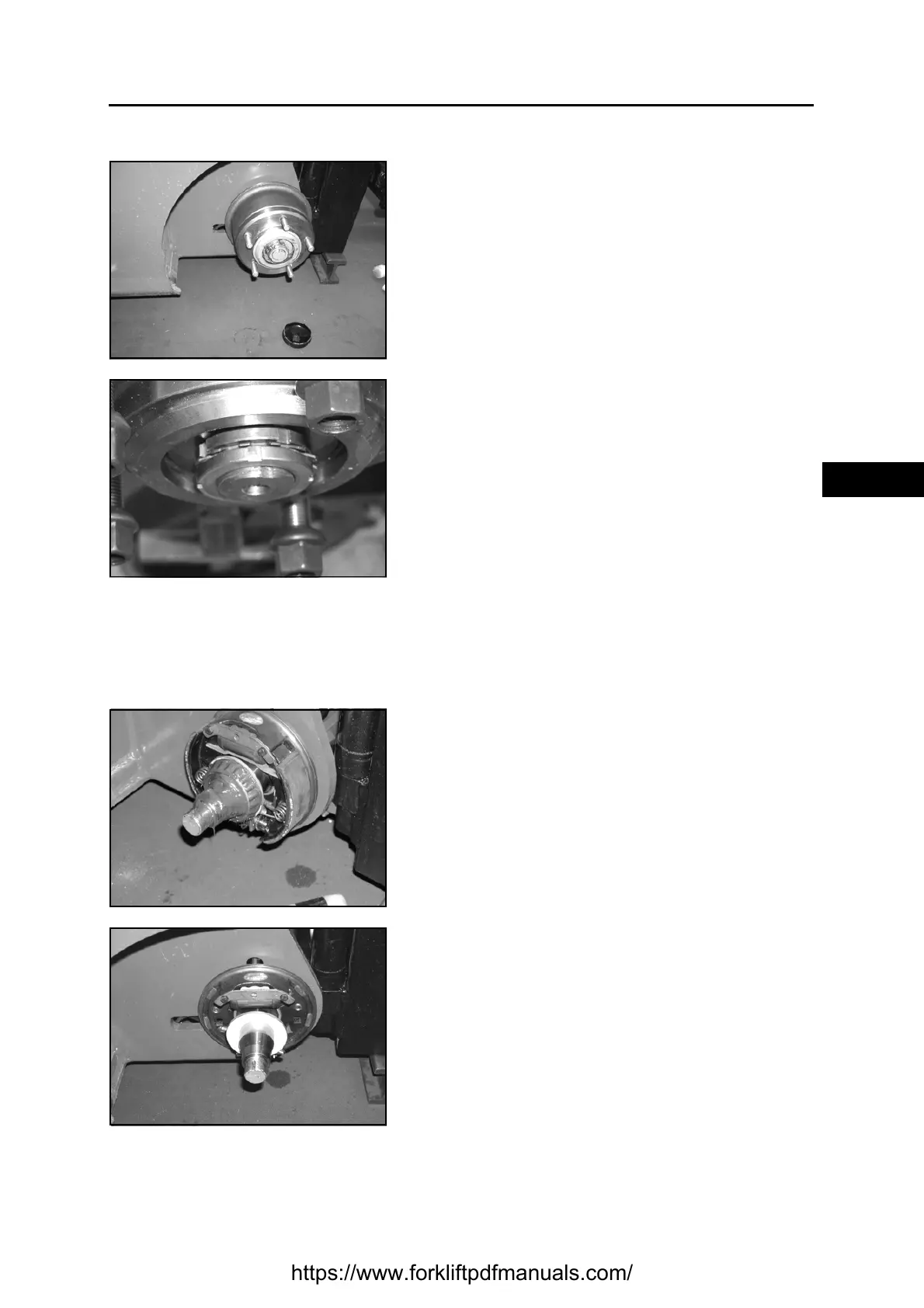

Disassembly:

Remove the hub wheel, pay attention not to damage it

Reassembly:

After installation, put 1/3 of appropriate grease inside

the cover (around 30gr.) well distributed

[Point 2]

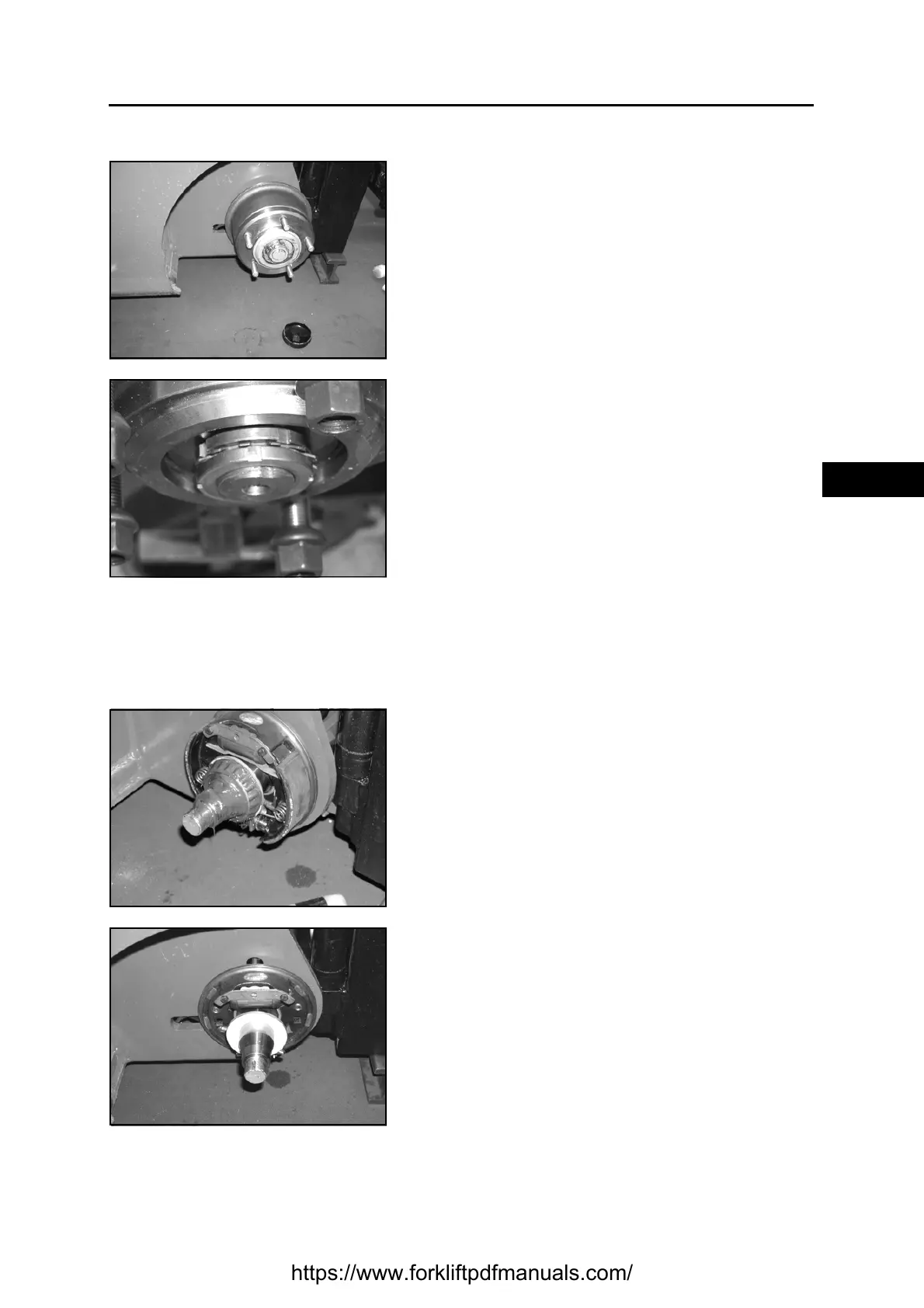

Disassembly:

Before removing the bearing nut (item 16B) it is

necessary to bend the teeth of the safety washer (item

17). Then remove also the bushing (item 16A)

Reassembly:

It is necessary to fit the 2 bearing nuts with the conical

surface orientated towards the frame (this is because

less friction is required between these parts and avoid

any damaging cause by the turning of the bearing-

wheel). After installation, tight the bearing nut (item

16A) with a torque of 60 Nm, then turn the wheel hub

2-3 turns in both directions sides in order to adjust the

bearings.

Then loose the bearing nut and tight it again with a

torque of 20 Nm (with this operation 0,6-1 Nm of

turning torque is obtained)

[Point 3]

Disassembly:

Remove the large conical bearing (item 6)

Reassembly:

After installation, put the appropriate grease with the

correct quantity the bearings. On the big conical

bearing 6 cover it of grease but do net exceed over the

diameter of the Nilos-ring (item 9) located on its rear

side

[Point 4]

Disassembly:

Remove the Nilos-ring (item 9) (this is used to seal the

bearings)

Reassembly:

For the installation it is necessary to replace this part

https://www.forkliftpdfmanuals.com/

Loading...

Loading...