79032966 A Rev. 01-19

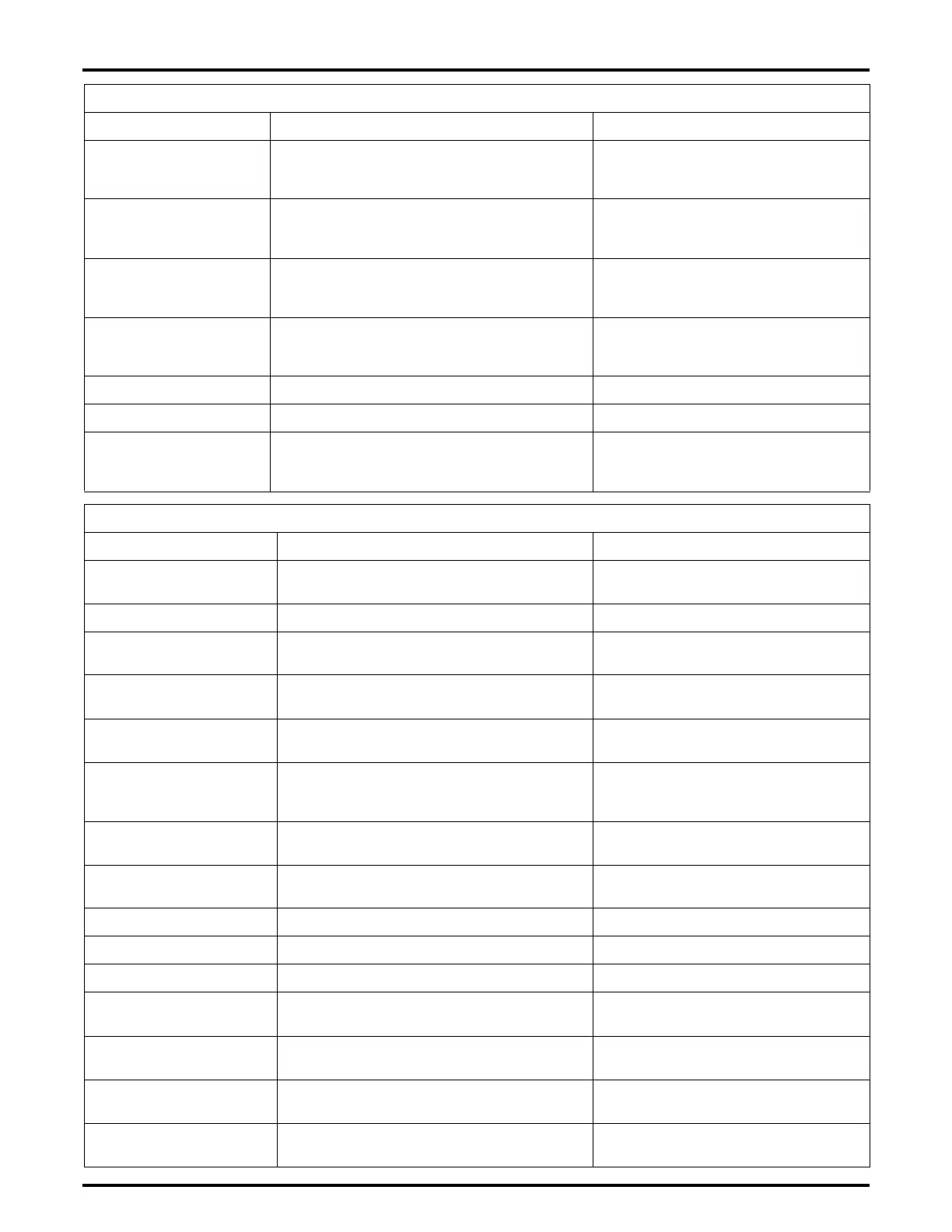

General Information

Hydrostatic

Rotor/Propulsion Pump

Drive Belt

Check tension and adjust as required. Especially important when operating

on hilly terrain to assure engine

braking assistance.

Radiator Coolant Check level of coolant in radiator coolant

recovery tank, with combine parked on level

ground, and add coolant if necessary

Use solution of 50% water and 50%

diesel type low silicant antifreeze. Do

not use Organic Acid type antifreeze.

Radiator Core and

Rotary Screen Air Intake

Check to ensure screen and radiator core are

clear of chaff and dust

Check twice daily in extremely dusty

conditions. Check that screen is free

to turn before starting engine.

Separator Pan

(Operating in mud and/or

snow conditions)

Check for buildup of material Clean as necessary through side

access doors.

Shoe Grain Pan Check for build-up of material.

Transverse Fan Check for build up of dirt and trash

Wheel Hardware Check torque every 10 hours or until the

wheel hardware remains tight

Refer to the Specifications section for

the correct wheel hardware torque

specification.

10 Hour or Daily Maintenance

Component Action Required General Information

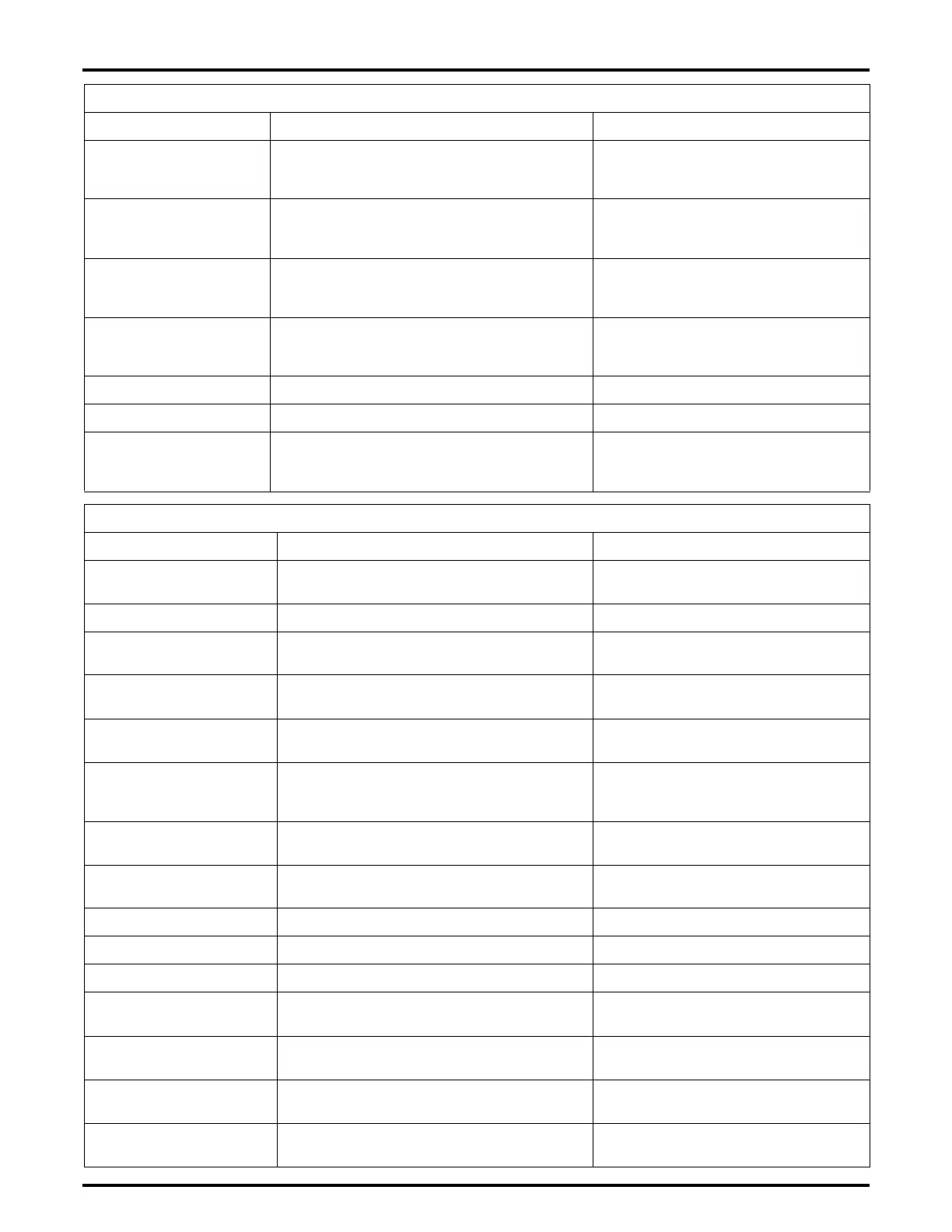

50 Hour or Weekly Lubrication

Component Action Required General Information

Clean Grain Elevator

Drive Idler Pivot

Lubricate one fitting At pivot on left-hand side.

Pitman Drive Idler Pivot Lubricate one fitting At pivot on left-hand side.

Rotor Gearbox Shaft

Spline

Lubricate one fitting Below battery disconnect switch.

Cleaning Fan Drive Idler

Pivot

Lubricate one fitting In grease bank on the front of the

clean grain elevator.

Front Rotor Bearing Lubricate one fitting In grease bank on the front of the

clean grain elevator.

Return Elevator

Countershaft Drive Idler

Pivot

Lubricate one fitting In grease bank on the front of the

clean grain elevator.

Straw Chopper/Spreader

Primary Drive Idler

Lubricate one fitting In grease bank on the front of the

clean grain elevator.

Straw Chopper/Spreader

Secondary Drive Idler

Lubricate one fitting In grease bank on the front of the

clean grain elevator.

Auger Pivot Tube Lubricate one fitting In the front left-hand side grease bank.

Front Beater Drive Idler Lubricate one fitting In the front left-hand side grease bank.

Unloader Drive Idler Lubricate one fitting In the front left-hand side grease bank.

Main Countershaft Drive

Idler

Lubricate one fitting In the rear left-hand side grease bank.

Propulsion Pump Drive

Idler

Lubricate one fitting In the rear left-hand side grease bank.

Rotor/Propulsion Pump

Drive Idler

Lubricate one fitting In the rear left-hand side grease bank.

Pivot Drive Idler Hub Lubricate one fitting On the left-hand side of feeder

housing.

Loading...

Loading...