79032966 A Rev. 01-47

General Information

DRIVE BELTS

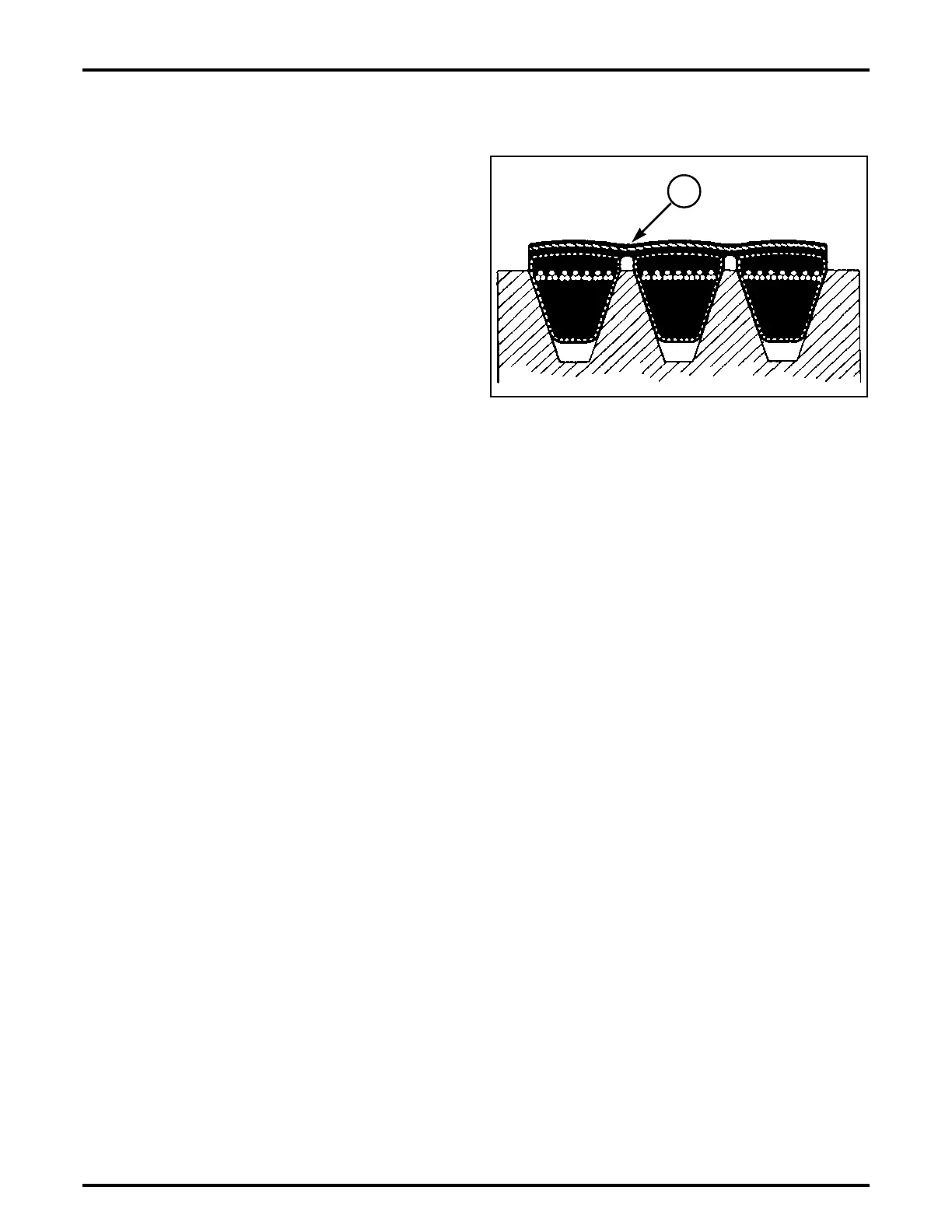

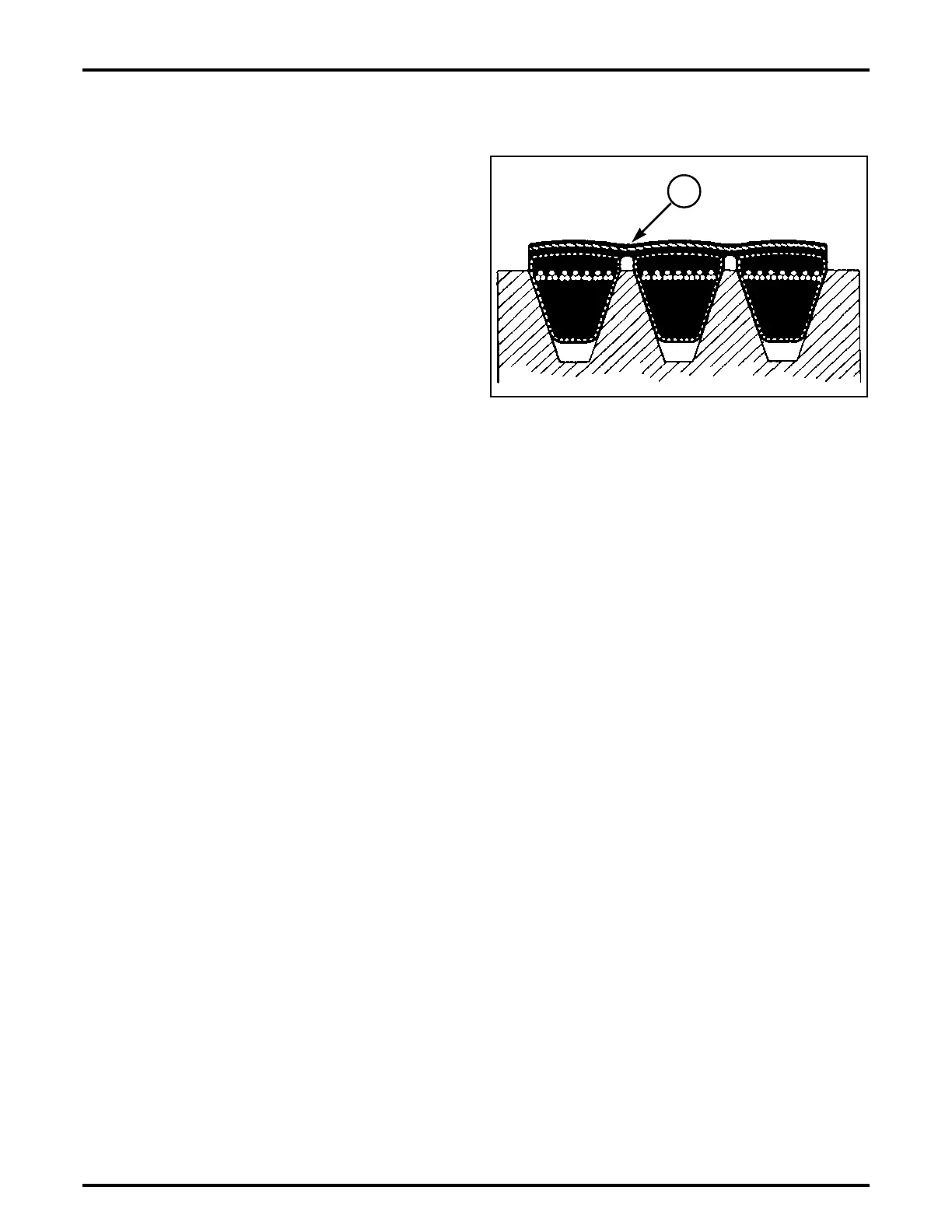

Banded Drive Belt

FIG. 96: A banded drive belt is made of two or more

V-belts (of a standard cross section size) banded together

at the top with a tie band (1). The seperate V-belts and the

tie band are vulcanized together to form a multiple strand

banded belt.

The cross section and spacing of the seperate strands

are such that the banded belt operates on standard

sheaves.

The tie band clears the top of the sheaves so that each

belt strand has full wedging capacity in the sheave

grooves, just as a single belt. The banded belt operates at

the same tension as seperate matched belts on an

regular multiple strand V-belt drive.

Most V-belt drives operate without any problem, requiring

only regular maintenance. There are times where forces

acting on the drive can cause seperate belts to whip, turn

over, or come off the sheaves. The banded belt was

designed to correct these belt stability problems which are

most frequently caused by intermittent or shock loading of

the drive.

Banded belts have standard dimensions and cross

section sizes and are made to order, with the number of

strands being determined by the power needs of the

drive. Spacing between the strands of the belt are the

same as the Rubber Manufacturers Association (RMA)

standard spacing for multiple groove sheaves.

FIG. 96

1

D-6150

Loading...

Loading...