General Information

01-48 79032966 A Rev.

Maintenance of Belts

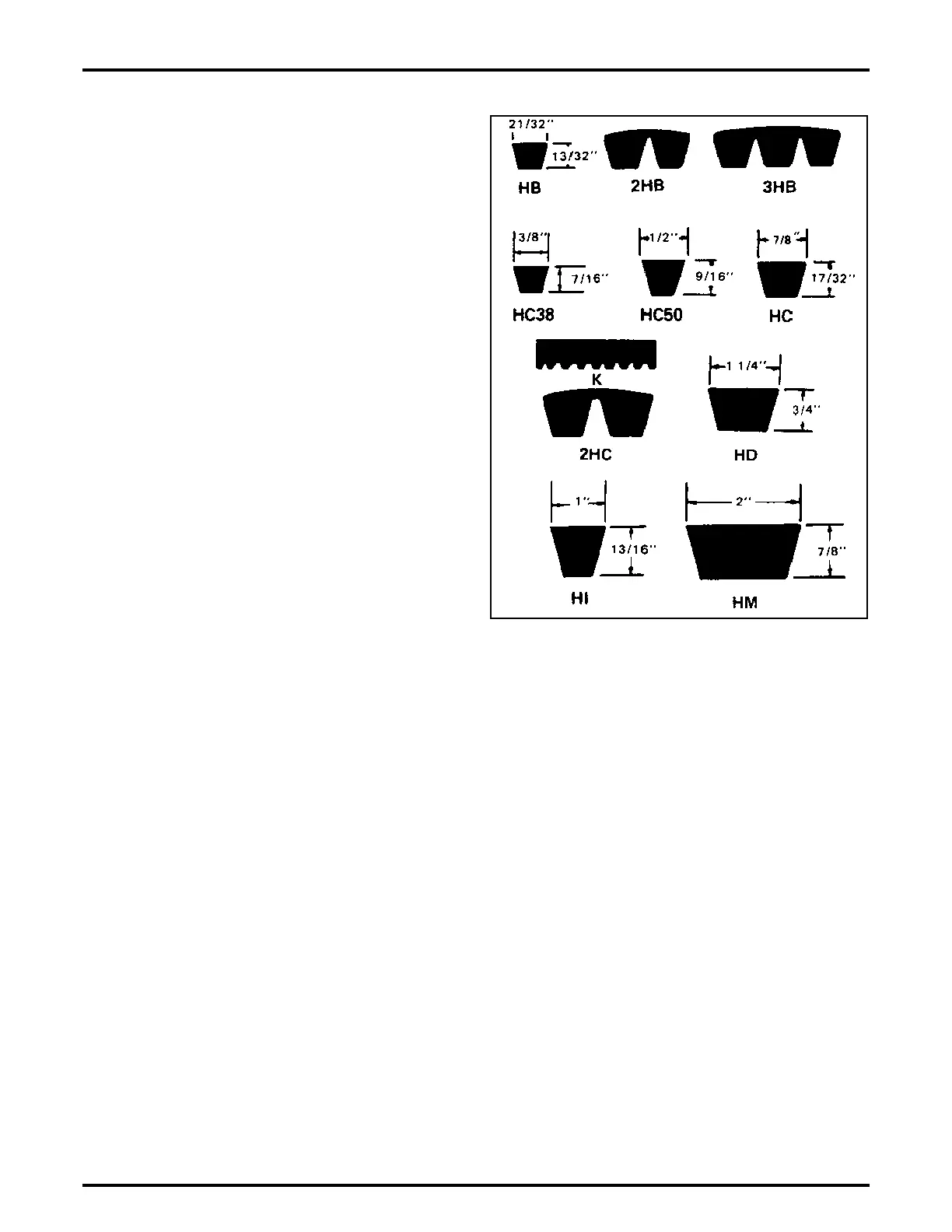

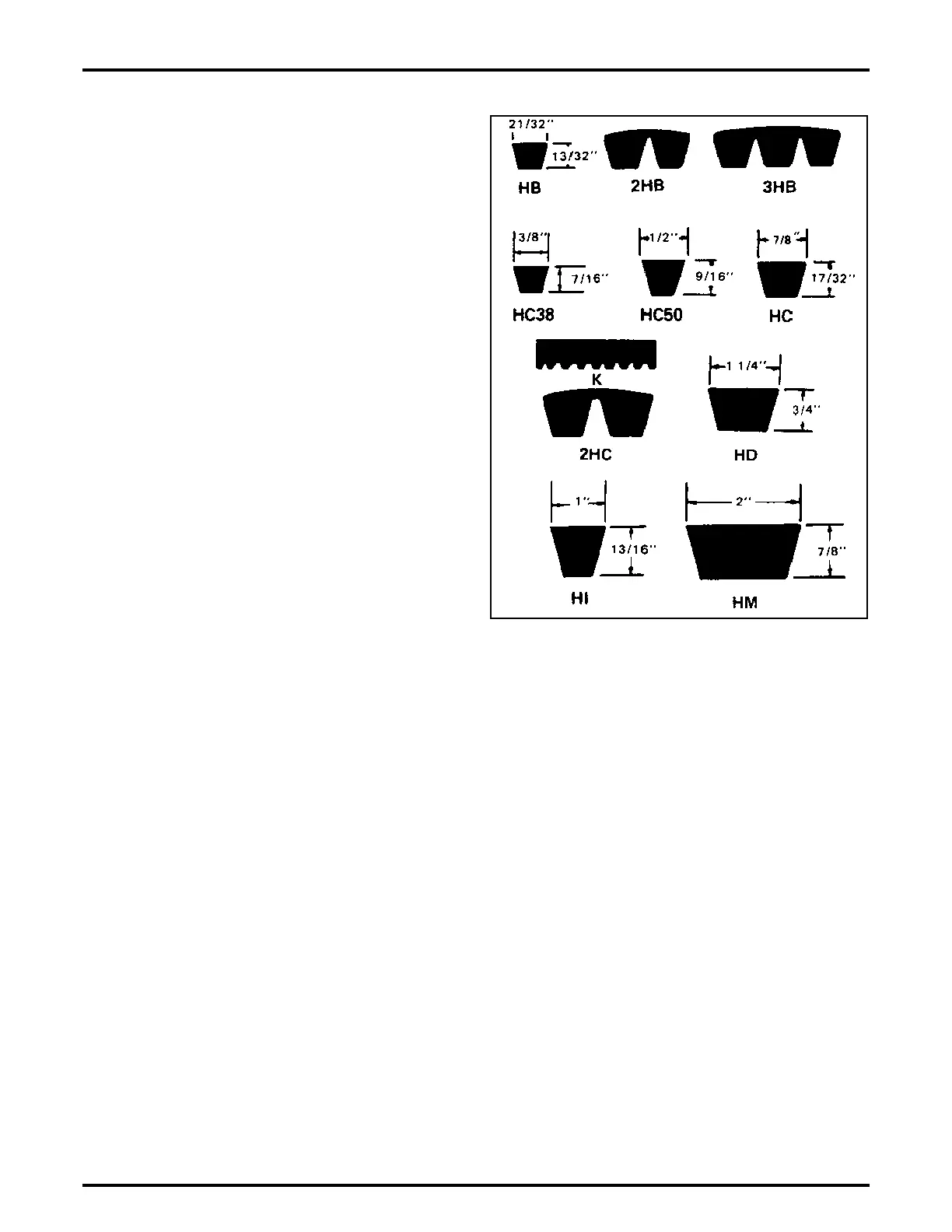

FIG. 97: Cross sections of some of the belts used on the

combine are shown.

A drive inspection must be done every one to two weeks.

Check belts frequently for excessive wear, tearing,

breaking, increasing, and unraveling.

Belt tensions are controlled with spring loaded idlers on

most drives on the combine. Over tightening puts too

much strain on the belt and too much loading on the

shafts and bearings.

Look and listen for any not normal vibration or sound

while watching the drive in operation. A drive kept in good

condition will operate smoothly with little noise.

Inspect guards for looseness or damage. Keep all guards

free from debris, dust, or grime deposit on either the

inside or the outside of the guard. Deposits of material on

guards operate as insulation causing drives to run hotter.

Belts that are running hot, running in a hot environment,

or from slipping will harden and form cracks from the

bottom of the belt up.

An internal temperature increase of 10 degrees C (18

degrees F) can cut belt life in half.

Inspect for oil or grease leaking on the drive. This can

indicate over lubricated bearings or a fluid leak. If this

material gets on rubber belts, the belts can increase in

size and become distorted, causing an early belt failure.

Belts must be replaced if there are signs of cracking,

fraying, or not normal wear.

FIG. 97

D-5594

Loading...

Loading...