- 23 -

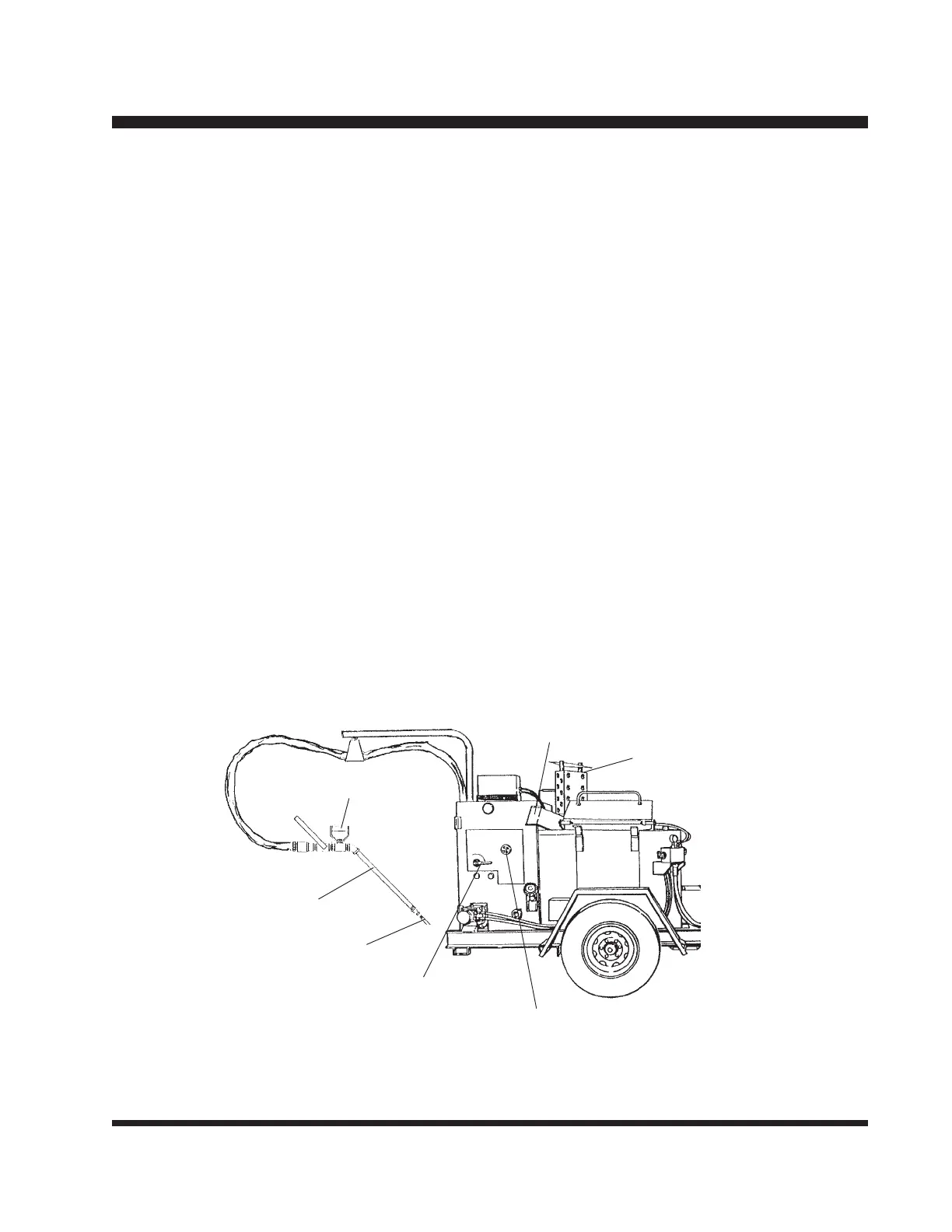

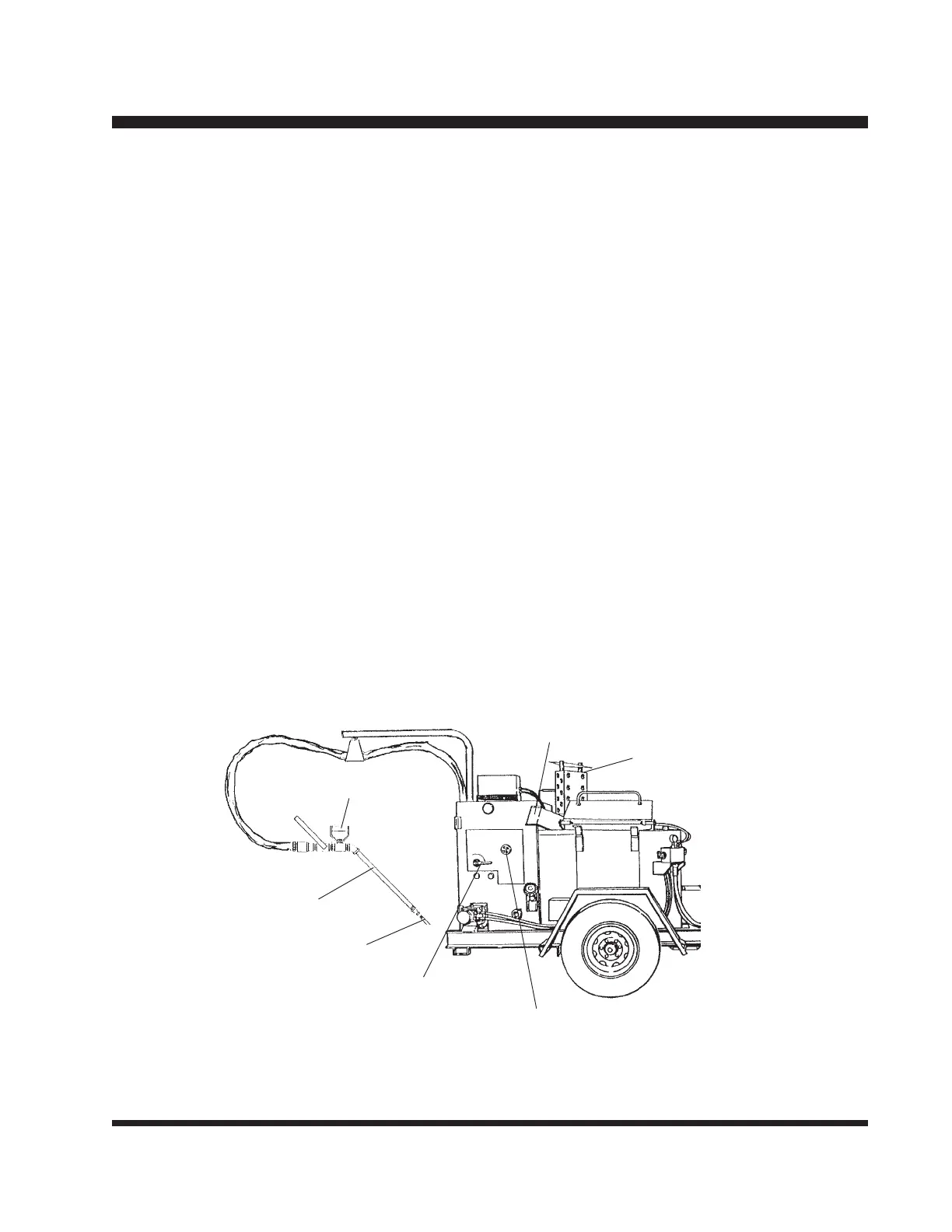

SEALING TIP

WAND

ACCESS PORT

WAND VALVE

SEALING HOSE VALVE

PRESSURE VALVE

STACK DIVERTER

(Propane units only)

Unplugging a Clogged Hose

2) If the unit is not full of material, add material to lower the tank temperature enough so the

control box will fire the burner. Keep adding material until the cabinet temperature is

high enough to unplug the hose.

NOTE: Be sure to open the thermal regulating gate to the full open position. On

propane units, be sure the stack diverter is closed.

3) If the unit is full, it may be necessary to open up the loading door and allow the material

to cool down. Turn the temperature control setting to 250º F. Allow the material to cool

down enough so that the burner will have to run for a period of time long enough to heat

the hose sufficiently. The actual time required will vary depending on how much material

and what type of material is left in the hose. Thermal regulating gate must be wide

open. On propane units, the stack diverter must be closed.

4) If the unit is clogged and the above two procedures are not possible, it may be neces-

sary to use a back up hose. The clogged hose can then be connected and unplugged

the next time you start up with a cold material tank.

The above situations illustrate the importance of properly cleaning the hose after use. It also

shows the importance of returning the hose to the access port during times between use to

keep the material flowing freely through the hose.

Loading...

Loading...