- 24 -

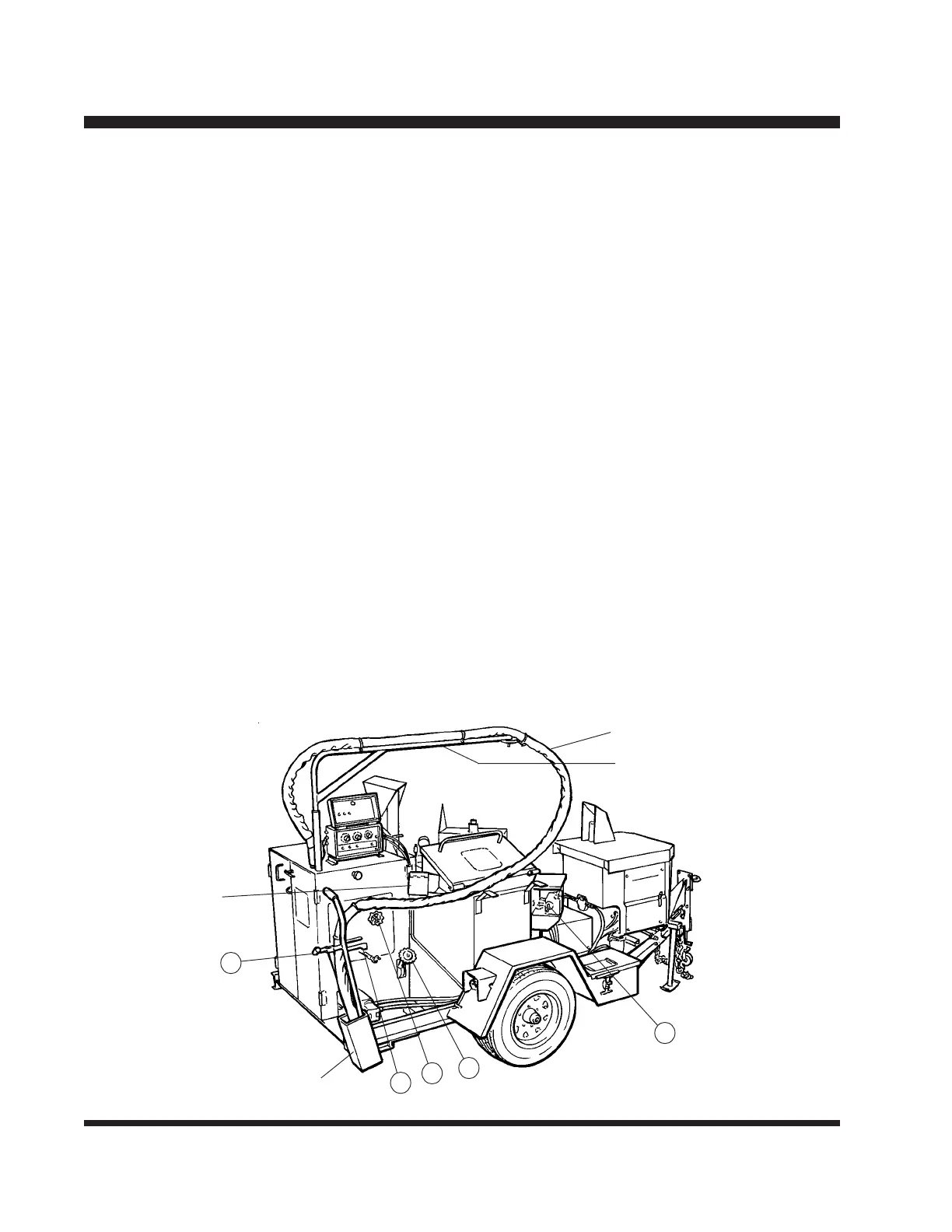

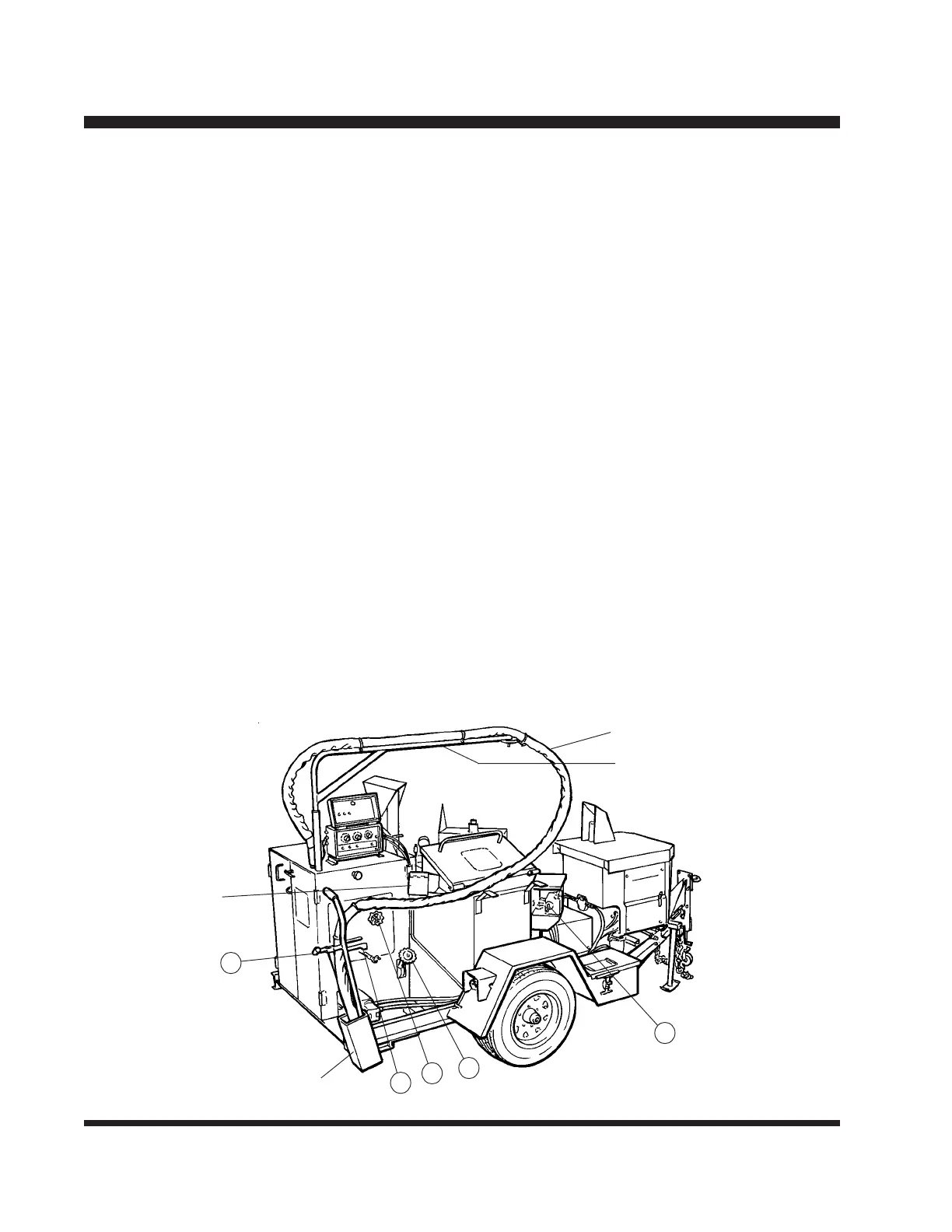

C

D

B

A

F

SEALING HOSE

WAND HOLDER

HOSE BOOM

ACCESS PORT

Material System Cleanout

Approximately 10-15 minutes before the end of the work period, turn the temperature control

knob(s) "off". There are three methods of cleaning that can be used; reverse flow, air and

solvent flushing.

NOTE: The material loading doors and wand access port must be closed at all times.

REVERSE FLOW CLEANOUT METHOD

1) To clean out the machine at the end of the day, return the wand to the wand return and

open the wand valve (F). Turn the pressure valve (B) clockwise until closed and reverse

the material pump by turning the material pump drive knob (C) clockwise. Run the

pump in reverse for 2 - 3 minutes.

2) With the hose still in the hose holder, elevate the hose over your head and physically

walk the length of the hose, shaking it to drain any residual sealant out of the hose.

3) Close the sealing hose valve (A) by turning clockwise, and continue with pump in re-

verse for 2 - 3 minutes.

4) Close the tank outlet valve (D) by turning clockwise.

5) Turn the pump off and open the pressure valve by turning counterclockwise.

6) Coil the hose back into the heating cabinet and shut the machine down (Non-heated

hose models only).

Loading...

Loading...