13

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

5. Pull the roller off the drive spindle.

• The groove size is stamped on

the corresponding side of the

roller. Select the groove size

according to the size of the

wire you are using and put the

roller back on the spindle with

your chosen side facing you.

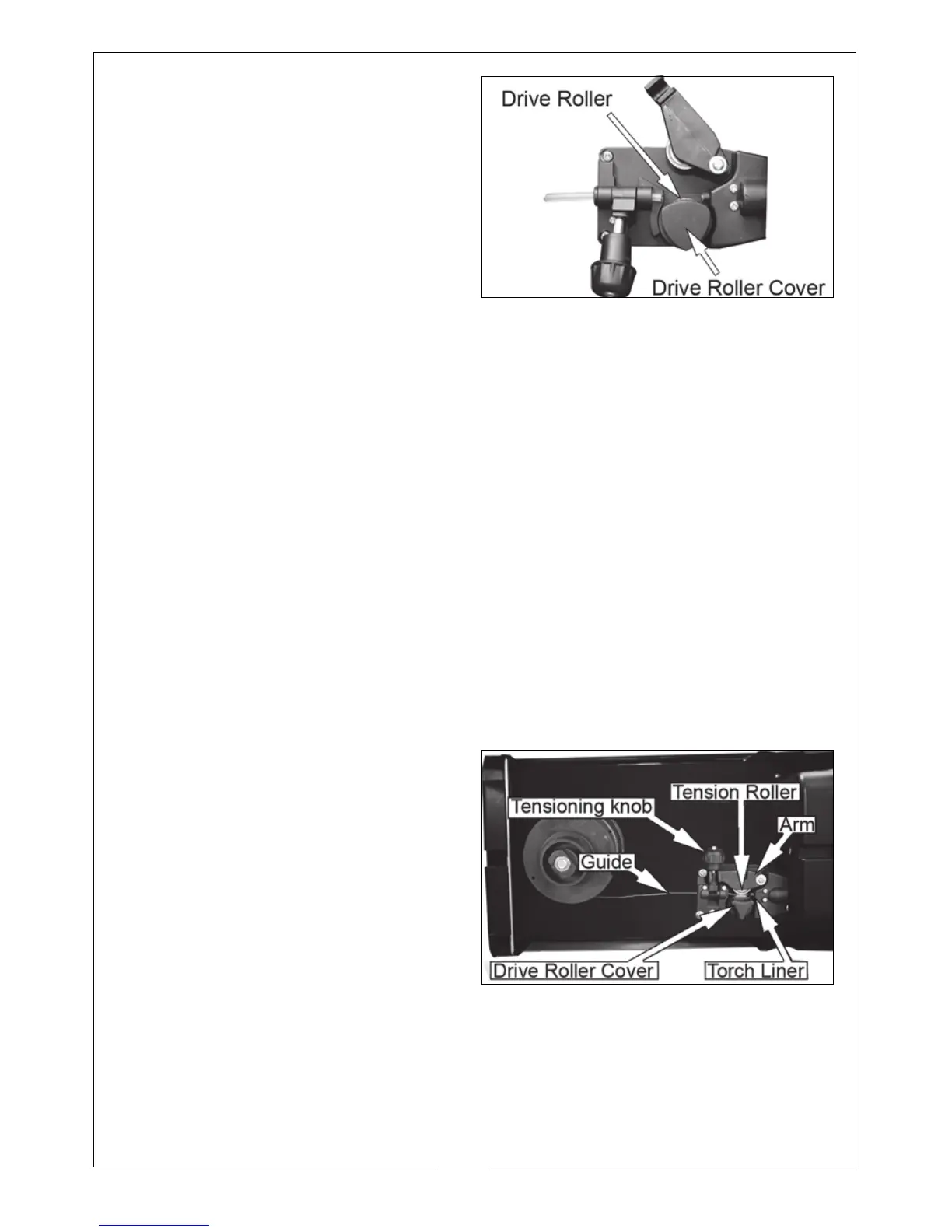

6. Replace the drive roller cover

back onto the drive spindle with

the opening facing right.

7. Ensure that the flanges at the base of the drive roller cover, seat fully into

the circular recess in the main moulding and then rotate the drive roller

cover through 90° to lock it in place.

THREADING THE WIRE

IMPORTANT: Do not release the tension on the wire as it will unravel causing

feeding problems later.

1. Pull out the end of the wire from the spool, taking care not to release the

tension.

• We recommend you cut off and discard the first 10 cm of wire from

the spool to avoid burrs and then straighten the next 15 cm of wire

to help with feeding.

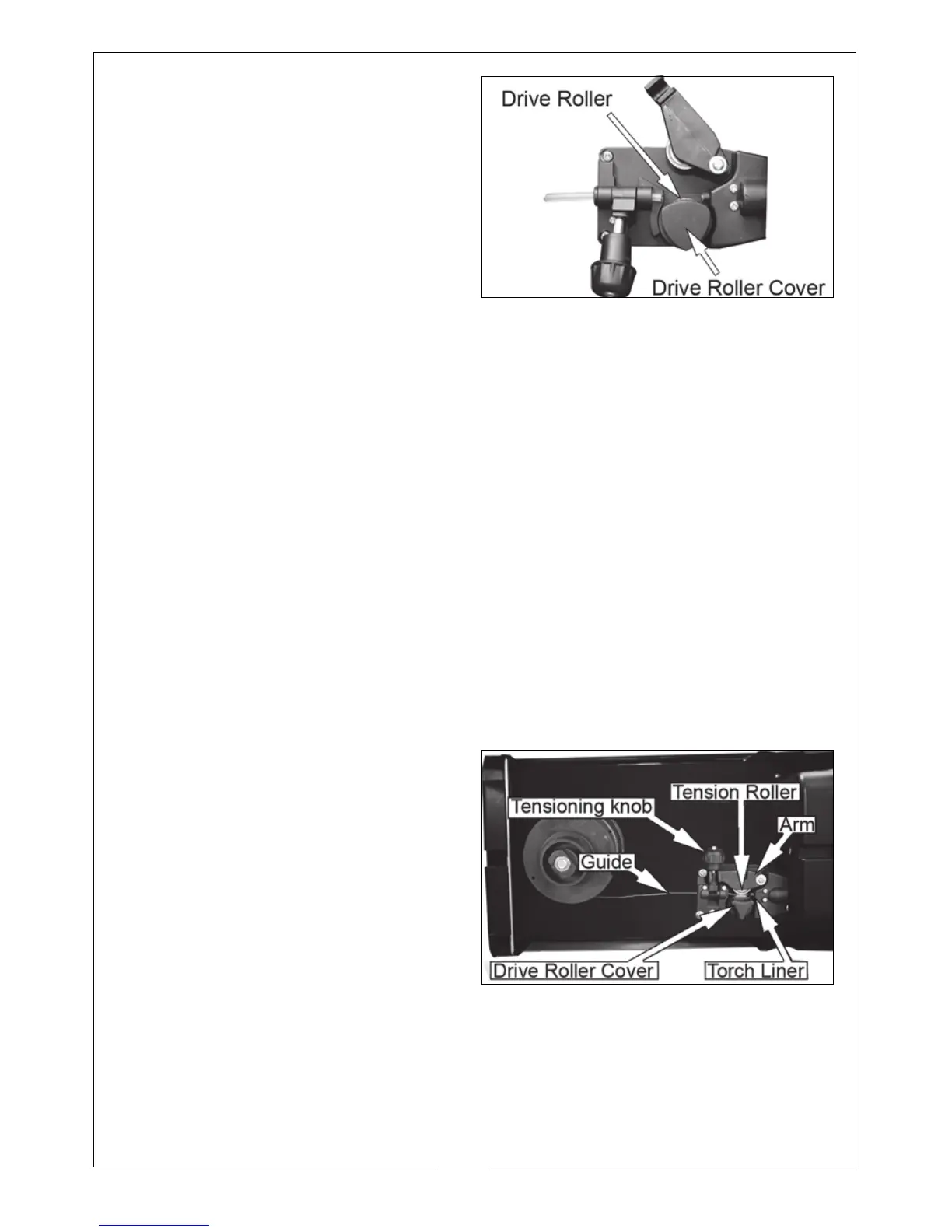

2. Loosen the tensioning knob and pivot it towards you.

3. Lift up the arm.

4. Pass the wire through the guide,

over the drive roller and into the

torch liner.

• Push about 10-15 cm into the

torch liner.

5. Lower the arm and replace the

tensioning knob.

• Tighten the tensioning knob

sufficiently to hold firmly, but do

not fully tighten.

NOTE: Correct tension will allow the wire to feed into the torch liner

smoothly, but will allow the drive roller to slip in the event of a

blockage.

Loading...

Loading...