20

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

TROUBLESHOOTING

Your CLARKE MIG Welder has been designed to give long and trouble free

service. If, however, having followed the instructions in this booklet carefully,

you still encounter problems, the following points should help identify and

resolve them.

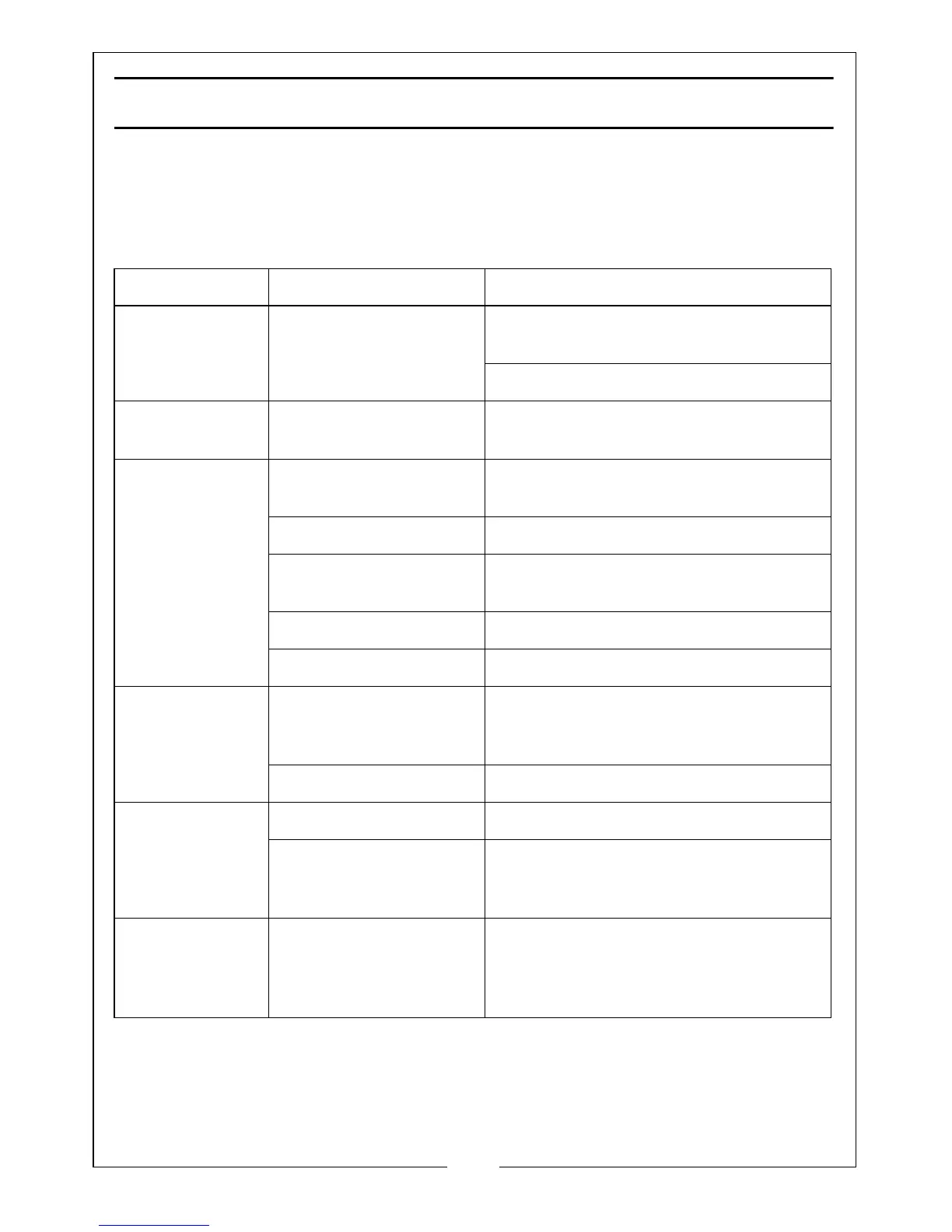

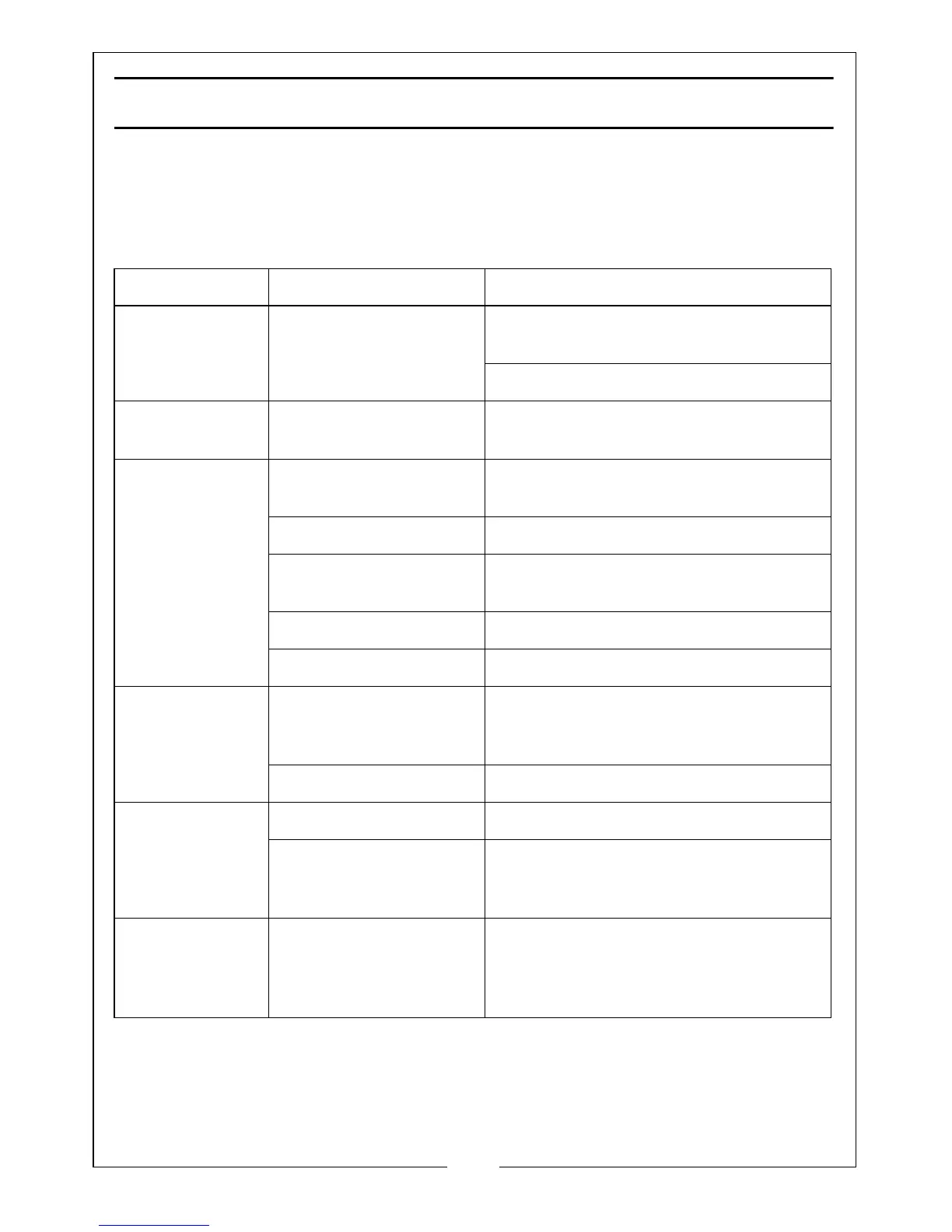

PROBLEM CAUSE SOLUTION

No response from

welder

Check fuses and mains

lead

Replace fuses as necessary, If problem

persists return welder to your local dealer

Check fuse size

Welder does not

feed wire

Feed motor has malfunc-

tioned.

Return welder to your local dealer

Feed motor run-

ning but no wire

being fed from

welder tip

Insufficient Feed Roller

pressure

Increase roller pressure

Burr on end of wire Re-cut wire square with no burr

Liner blocked or dam-

aged

Clean with compressed air or replace

liner.

Inferior wire Use only good “clean” wire

Roller worn out Replace roller

Wire welds itself

to tip

Wire feed speed too low Unscrew tip, cut wire and fit new tip

Increase wire speed before operating

again

Wrong size tip Fit correct size tip

Wire feeds into

‘birds nest’ tan-

gle

Wire welded to tip As above plus reduce feed roller pressure

Wire liner damaged pre-

venting smooth opera-

tion

Renew wire liner

Loose coils of

wire tangle

around wire drum

inside machine

Locking knob too slack Tighten Locking Knob slightly. Do not

over-tighten

Loading...

Loading...