4-13

ADJUSTING COOLANT FLOW

Step 1 – Press the saw blade start button to start the saw blade drive motor.

Step 2 – Use the flow control valve (shown below) to adjust the amount of fluid flowing to the cutting

area.

Adjust the flow amount if you observe the following changes to the chips generated from

cutting.

If the chips are sharp and curved, increase the coolant

flow amount.

If the chips are granulated, decrease the coolant flow

amount.

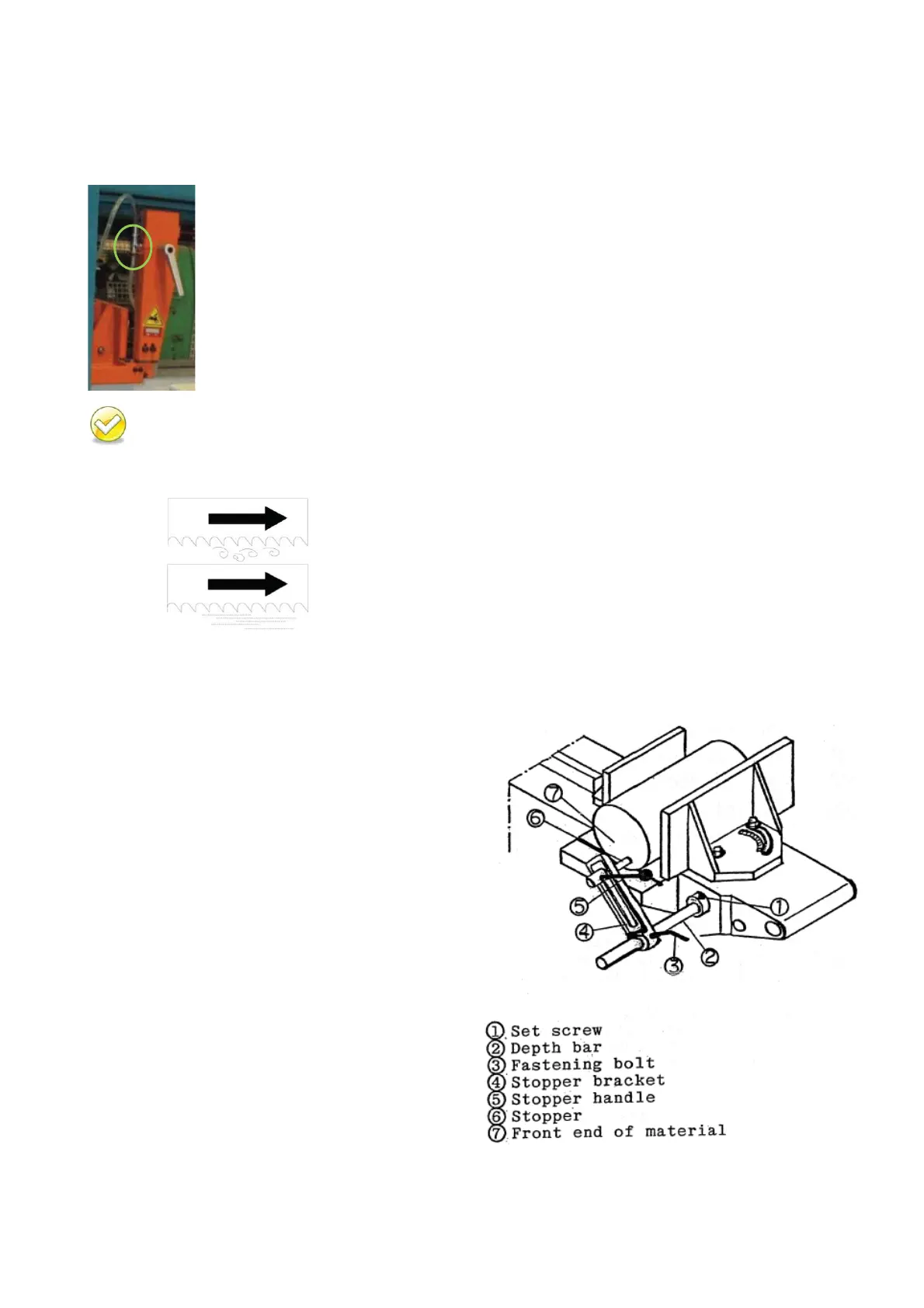

INSTALLING MATERIAL STOP BRACKET

This device is easy to cut the same length repeatedly and saves adjusting time.

Step 1 - Install the depth bar and tighten the set

screw.

The depth bar is taken off from the

machine base during transit for safety reason.

- Lift the saw bow and clamp material

-

Lower the saw bow to allow about 1 mm

clearance between saw blade teeth edge and the

top of the material. Then measure your desired

cutoff length.

- Loosen the fastening bolt.

- Slide and position the stopper

so that the

end of stopper faces the direction of the front

end of the material.

Then tighten the stopper

to fix the stopper in the bracket.

- Move the stopper bracket toward the

workpiece so the stopper end just to

uches the

front of the material, then tighten the fastening

bolt.

MS1318M / MS1318SA

Loading...

Loading...