Profire V Burner Chapter 2

750-177 2-15

FULL MODULATION - OPEN DAMPER PURGE

Combustion Air Gas Oil

COMPONENTS

DESCRIPTION

A two blade damper is controlled by a

proportional modulating actuator (or

motor) with mechanical linkage. The

modulating actuator is capable of

stopping at any point along its 90

degree stroke based on a signal from

a remotely connected modulating

control or from a burner mounted

manual potentiometer which is

selected through an auto/manual

modulation selector switch. The

actuator also contains two internal

switches that ensure the damper

reach the high fire and low fire

positions during purge and before

ignition is initiated.

Safety shut off valve(s) are provided

to initiate the flow of gas. The

primary is a diaphragm or motorized

type valve which have delayed

opening rates to prevent an "in rush"

of gas. A butterfly type gas metering

valve is linked directly to the damper

actuator and provides gas flow

metering relative to the actuators

position . A manually adjusted gas

regulator limits maximum firing rate.

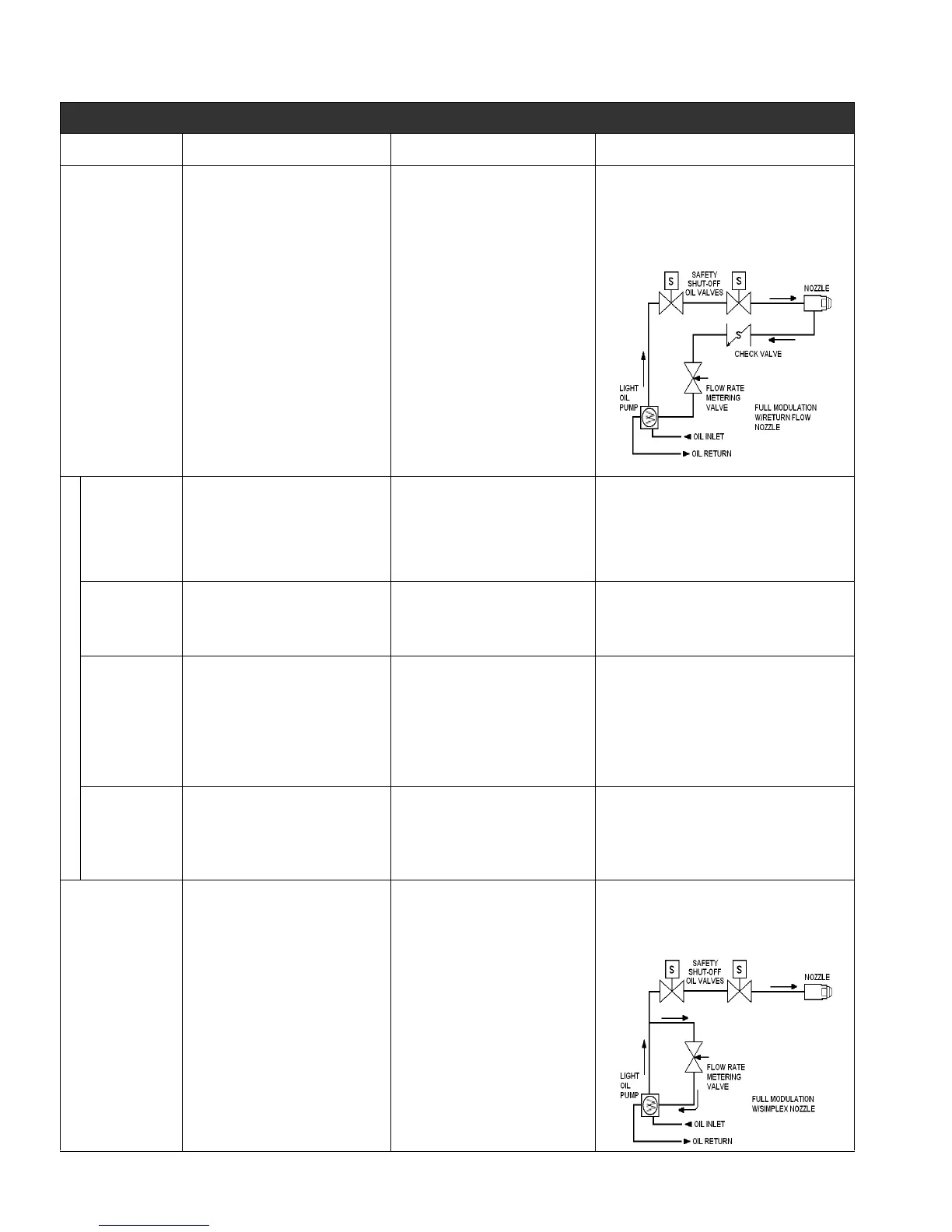

Pressure Atomization: Two solenoid type safety shut

off oil valves initiate the flow of oil from the high

pressure pump to a return flow nozzle. In the return

line from the nozzle an adjustable oil metering valve

limits the amount of oil allowed to return to the pump.

The metering valve is connected to the damper

actuator with mechanical linkage.

Operating Sequence

PRE-PURGE

From its closed position the damper

is driven open by a signal from the

flame safeguard control where the

high fire air switch is proven. The

damper will remain open for the

duration of the pre-purge cycle.

Valves are closed.

The pump is operational but the valves are

closed. Oil is flowing through an internal relief

valve and returning to the supply system.

STARTUP,

IGNITION

Damper returns to the low fire position

which is proven through the internal low

fire air proving switch. The burner is now

ready for startup.

Valves open. To prevent a surge the

primary gas valve opens at a slowed rate.

Gas flow to the manifold is metered based

on the butterfly valve low fire setting.

Safety shut off valves open allowing oil to flow from

pump to nozzle. Oil pressure at the nozzle is based on

the pump's pressure setting less the volume of oil

returning through the metering valve.

RUN,

MODULATE

Damper is driven by the modulating

actuator to a firing rate position as

determined by the modulating control or

manual potentiometer. Actuator can

complete full travel to high fire in 30

seconds. Actuator will then continue to

adjust firing rate position based on signals

from the modulating control until demand

is satisfied.

The gas valves remain in their open

position. As the actuator begins it's travel

to the firing rate position it is also

adjusting the butterfly gas metering valve

increasing the flow of gas to the manifold.

The burner will continue to modulate as

described under the combustion air

heading until demand is satisfied.

The safety shut-off oil valves remain open. As the

actuator begins it's travel to the firing rate position it is

also adjusting the oil metering valve decreasing the

amount of oil allowed to return to the pump. This in

turn is increasing the pressure and volume of oil at the

nozzle. The burner will continue to modulate as

described under the combustion air heading until

demand is satisfied.

SHUT DOWN,

POST-PURGE

Damper returns to its starting position

based on the 30 second closure speed of

the mechanical actuator during post purge.

On shut down all gas valves close within 1

second. The butterfly valve closes in 30

seconds with the damper actuator.

All valves immediately close. The metering valve

opens to it's low fire position in 30 seconds with the

damper actuator. The oil pump is operating with post-

purge, but oil is flowing through an internal relief valve

and returning to the supply system.

VARIATIONS:

Options are available for 4-20amp

modulating signal conversion or 4-20

proportional modulating actuators.

Also optional is an actuator with dual

low fire start switch positions for

improved "turn down" in dual fuel

situations.

None

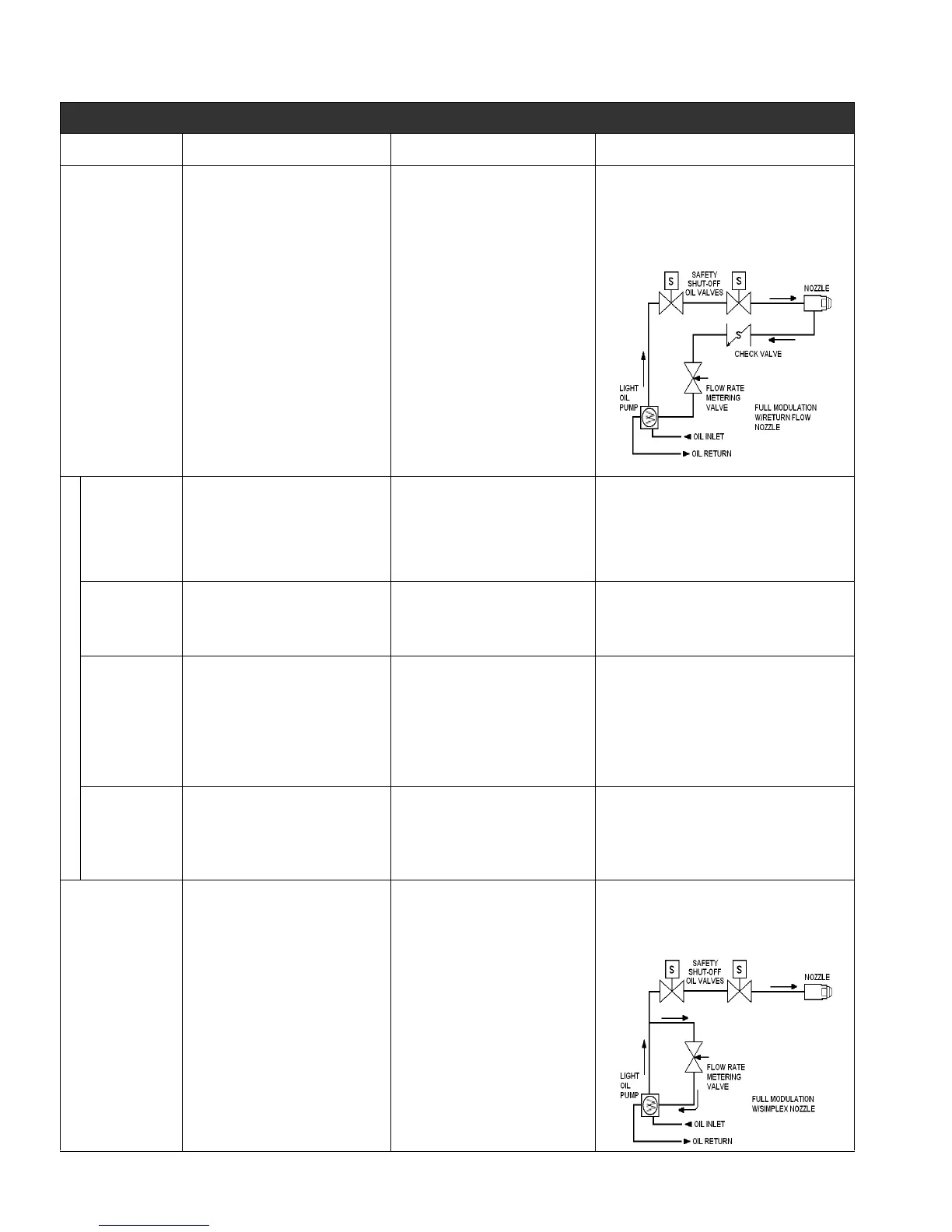

On models with a simplex nozzle oil is diverted

from the supply line through the meter and

back to the pump before the first safety shut-off

valve.

Loading...

Loading...